Integrated Cascading Plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

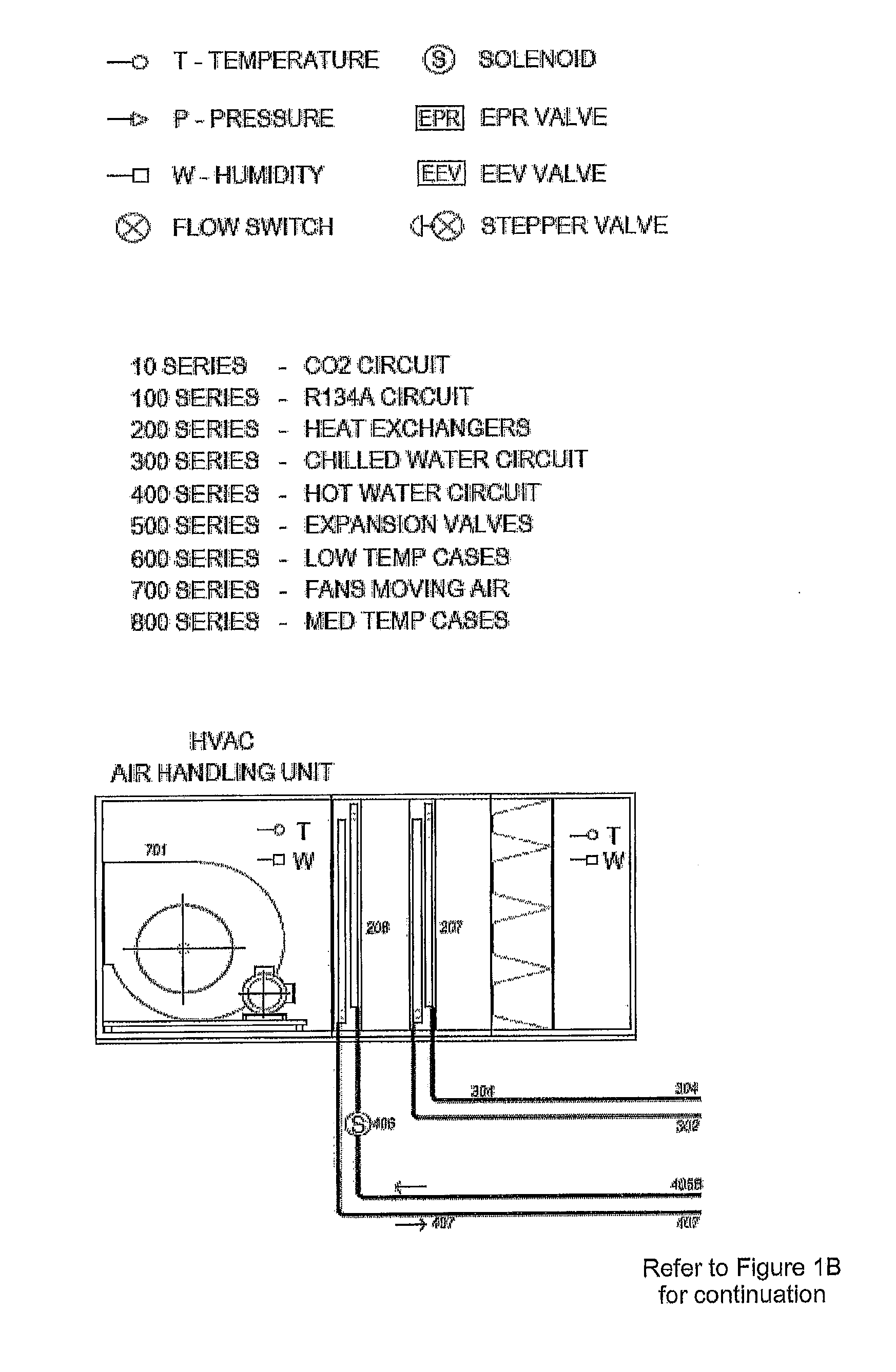

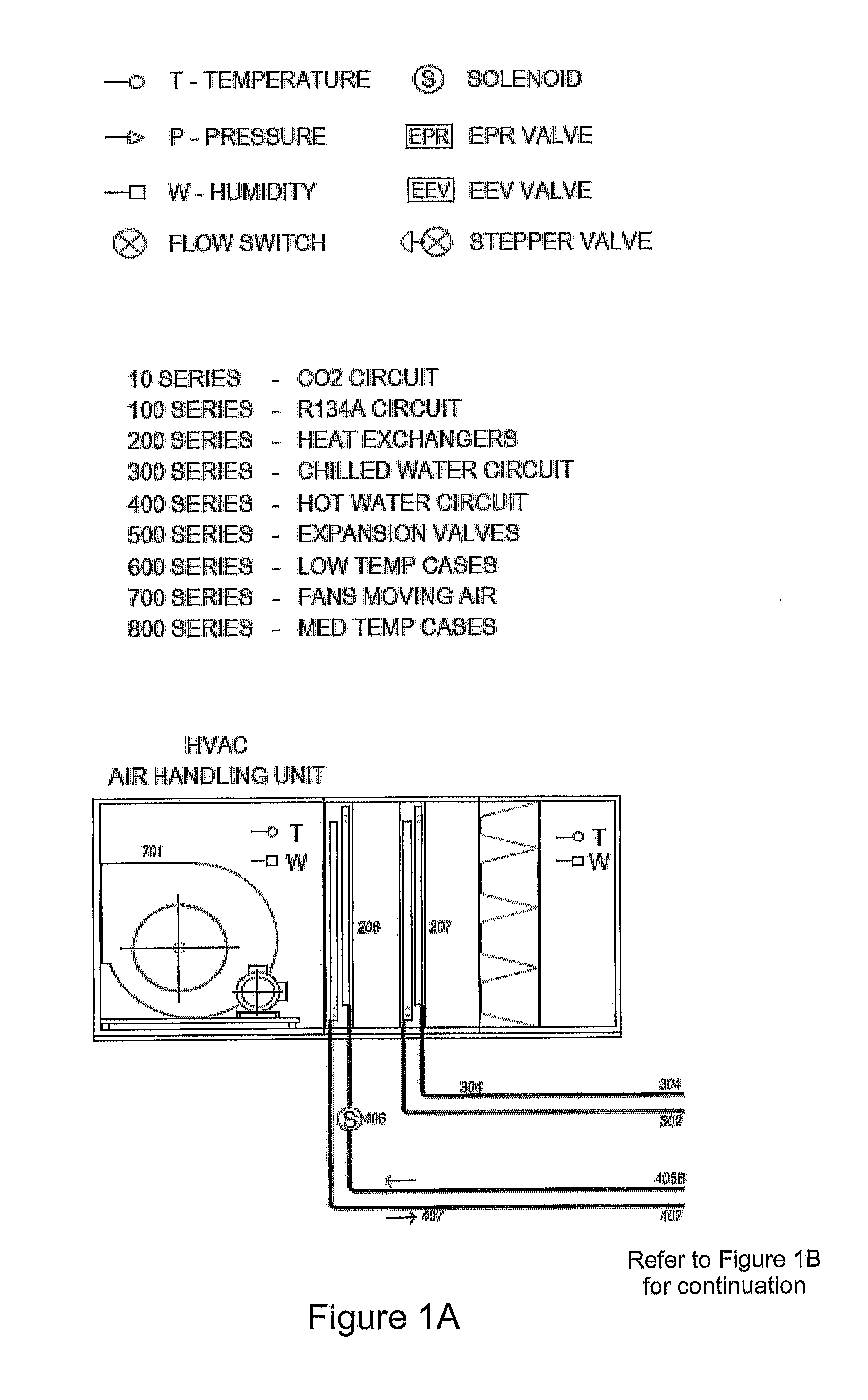

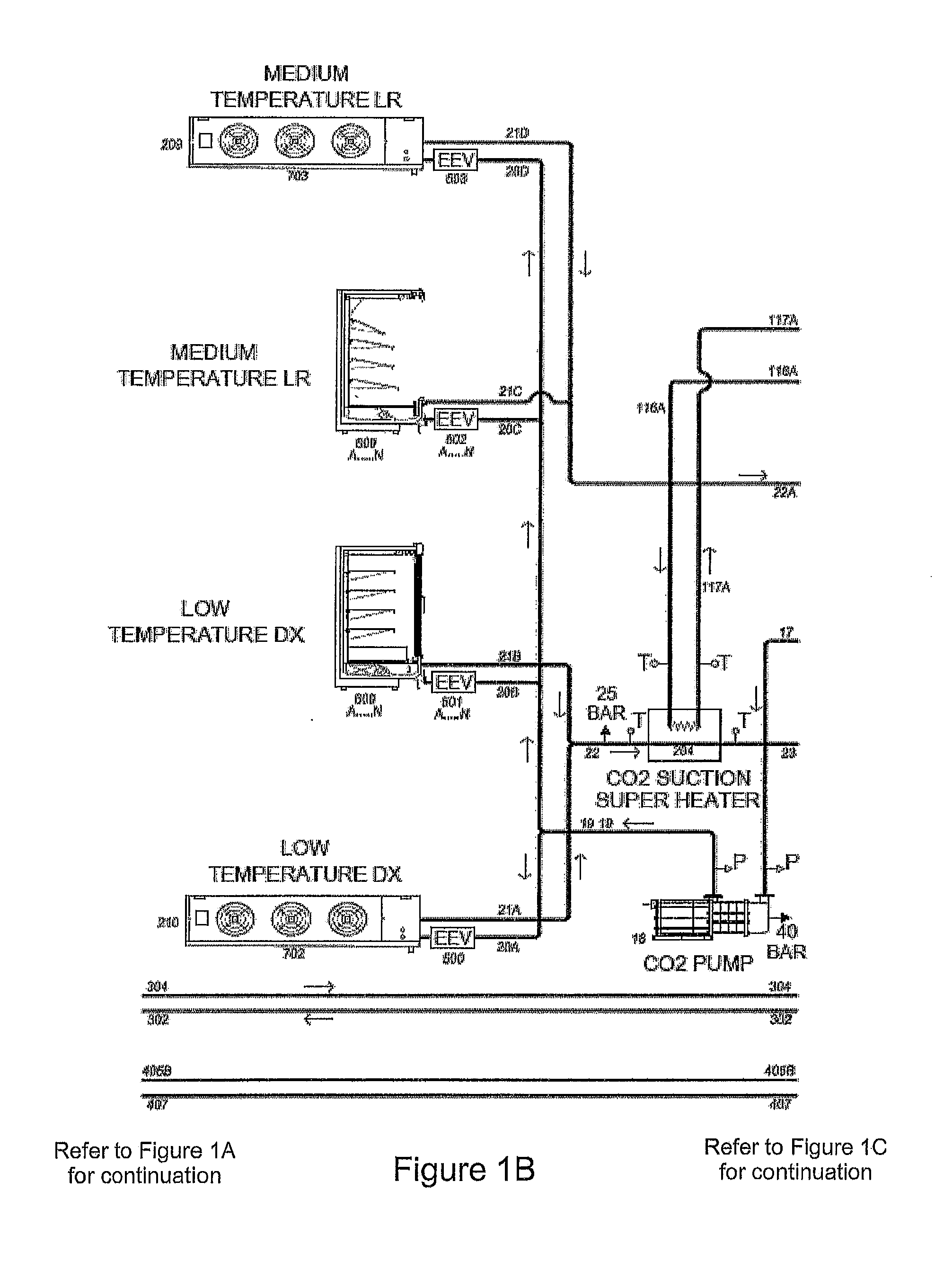

[0036]The invention will now be further illustrated with reference to the non limiting example depicted in the accompanying figure.

[0037]The low temperature segment (designated by 10 series of numbered components) operated in a closed cycle conventional vapour compressor refrigeration will have CO2 as the refrigerant and use a single or plurality of positive displacement type of compression system (10). The discharge gas of this compressor is directly led into the vapour line of CO2 entering the cascade heat exchangers (200 and 201). This vapour line not only receives the vapour from these compressors (13A and 13B), but also from the vapour space of the CO2 receiver (14A and 14B). An important requirement is that the CO2 liquid receiver (16) pressure (p16) must be matched with the discharge pressure (p13) of the compressor. Notionally, this pressure will be the saturation pressure of CO2 at the cascading temperature which is typically set at −7° C. in the description without prejudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com