Separating Fluid, Method And System For Separating Multilayer Systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

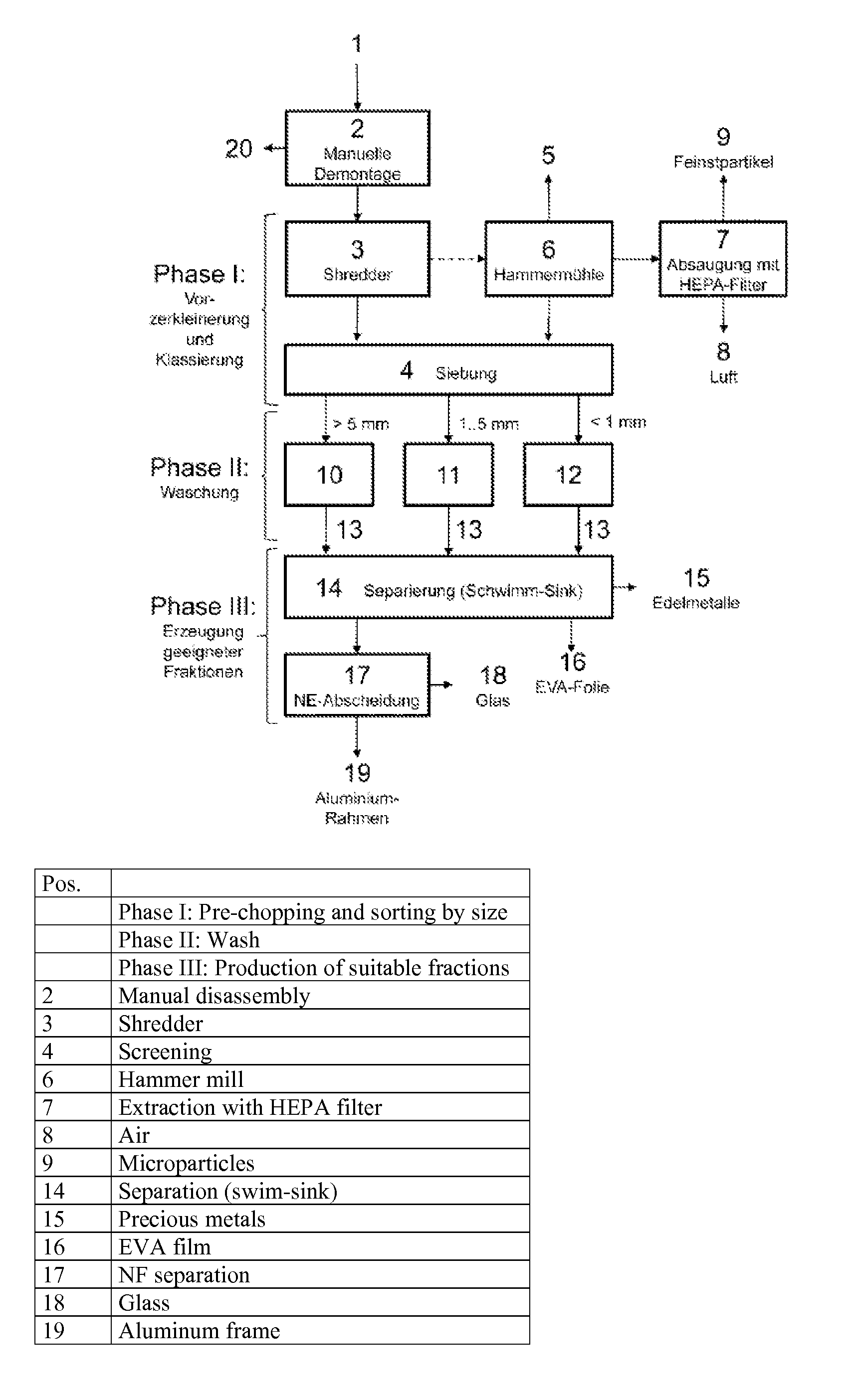

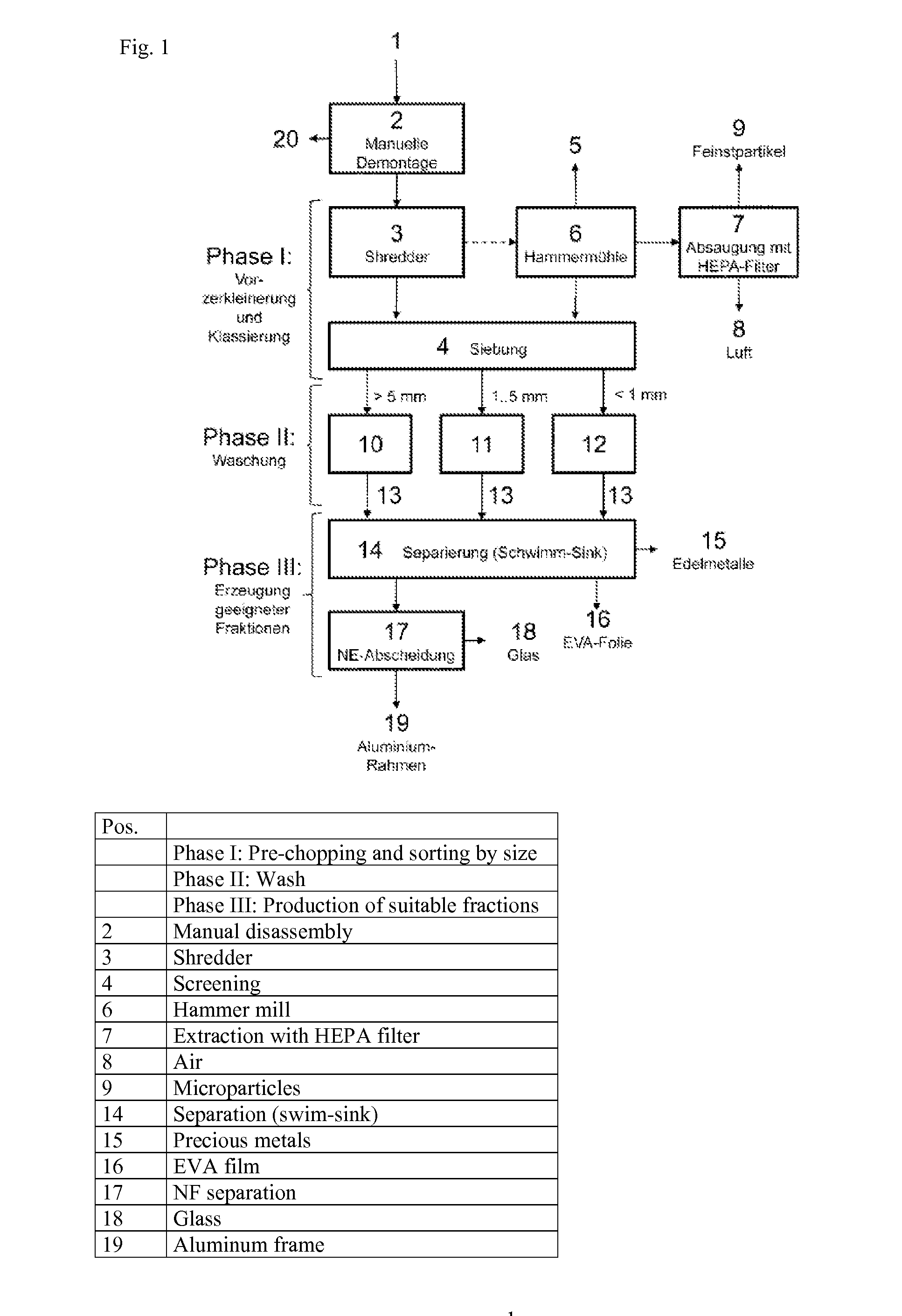

Method used

Image

Examples

example 1

[0078]

Contribution to% bythe aqueousComponentweightSubstancecomponentAnionic17.8Leuna alkane sulfonate 3011.8surfactant(sodium alkane sulfonatemixture with an averagechain length C15 (C12-C18) based on n-paraffin -34% watery solutionNon-ionic5.9Polyethylene glycol-surfactantmono-n-dodecyl / tridecyl / tetradecyl / -pentadecylether assubstance mixture ofcompositions with 4 to 25ethylenoxide unitsHydrotrope3.5Cublen R 60 [N-(2-1.4hydroxyethyl)-N,N-bis-methylenephosphonic acidin the form of a 60%watery solutionCo-surfactant8.9Butanol-2Organ. Phase7.0Xylen (techn.)Addition of water56.90Watery70.1Total of addition of watercomponent totaland contributions to thewatery component

example 2

[0079]

Contribution to% bythe aqueousComponentweightSubstancecomponentAnionic6.0Leuna alkane sulfonatesurfactant95 (sodium alkanesulfonate mixture withan average chain lengthC15 (C12-C18) basedon n-Paraffin)Non-ionic6.0Polyethylene glycol-surfactantmono-n-dodecyl / tetradecylether assubstance mixture with9 ethylenoxide unitsHydrotrope2.0Dimethylaminomethane-bis-phosphonic acidCo-Surfactant9.0EthylhexanolOrganic phase8.0MesitylenAddition of water69.0Aqueous69.0Total of addition ofcomponent totalwater and contributionsto the watery component

[0080]In the nanoscale dispersions according to example 2, NaOH may be added to increase the pH value.

example 3

[0081]

Contribution to% bythe aqueousComponentweightSubstancecomponentAmphoteric5.0N,N-dimethyl-N-surfactanttetradecyl-ammoniopropanesulfonateNon-ionic6.0Polyethylene glycol-surfactantmono-n-dodecyl / tetradecylether assubstance mixture with 9ethylenoxide unitsHydrotrope2.0Dimethylaminomethane-bis-phosphonic acidCo-Surfactant9.0EthylhexanolOrganic phase7.0Hydrosol P 180 EAAddition of water71.0Watery71.0Total of addition of watercomponent totaland contributions to thewatery component

[0082]In example 3, the anionic surfactant is replaced by an amphoteric surfactant in contrast to examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com