Device for blowing air by means of narrow slit nozzle assembly

a technology of nozzle assembly and nozzle, which is applied in the direction of piston pumps, lighting and heating apparatus, heating types, etc., can solve the problems of only being able to adjust the pitch of fans or circulators, failing to meet the requirement for adjusting the direction of air stream, and reducing the brightness of the room, so as to save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]To make the objectives, technical solutions and advantages of this invention understandable clearly, the invention is described in further detail below in conjunction with the drawings and embodiments. It should be understood that the embodiments are described for explaining this invention only and are not intended to limit the scope of this invention.

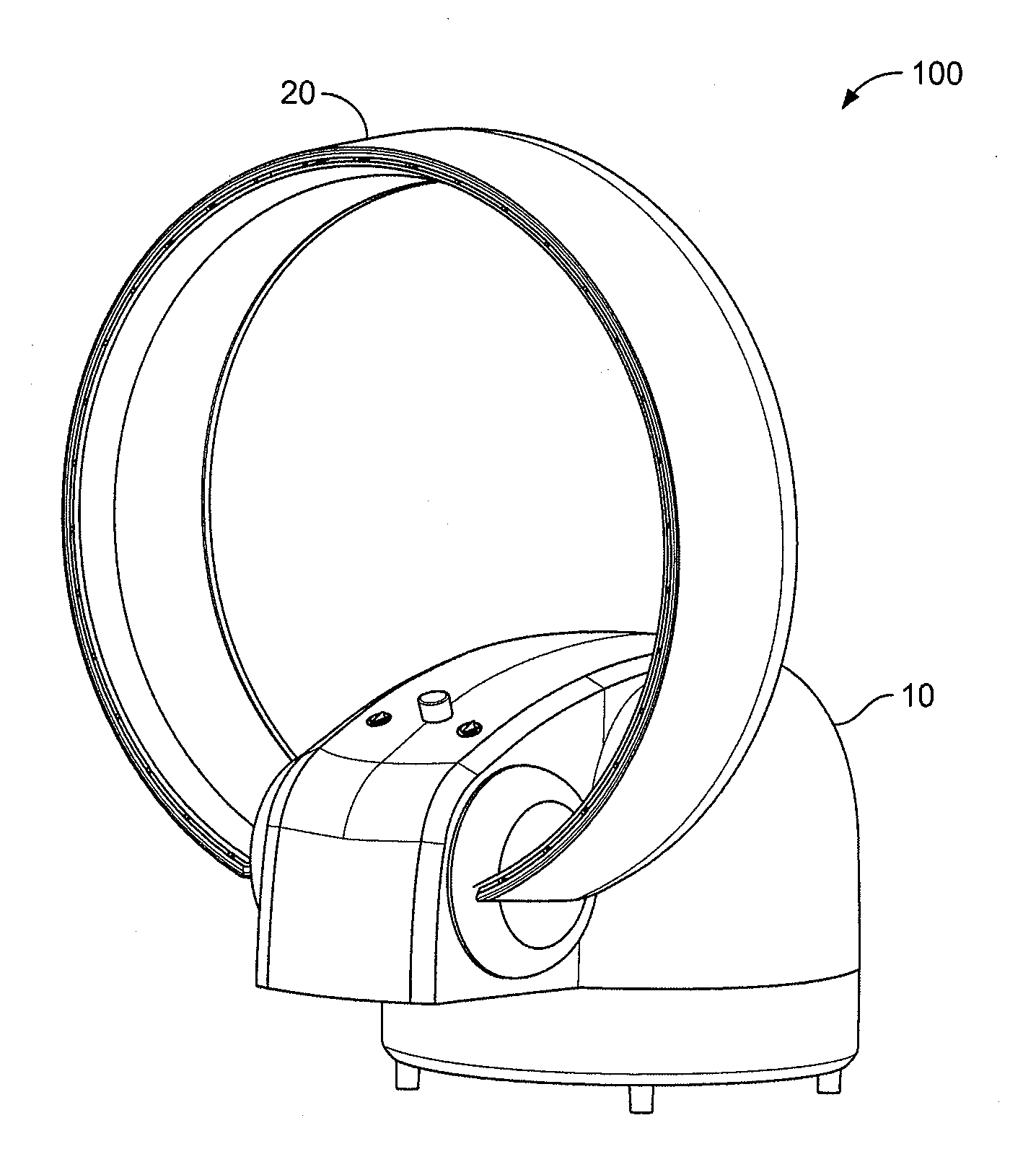

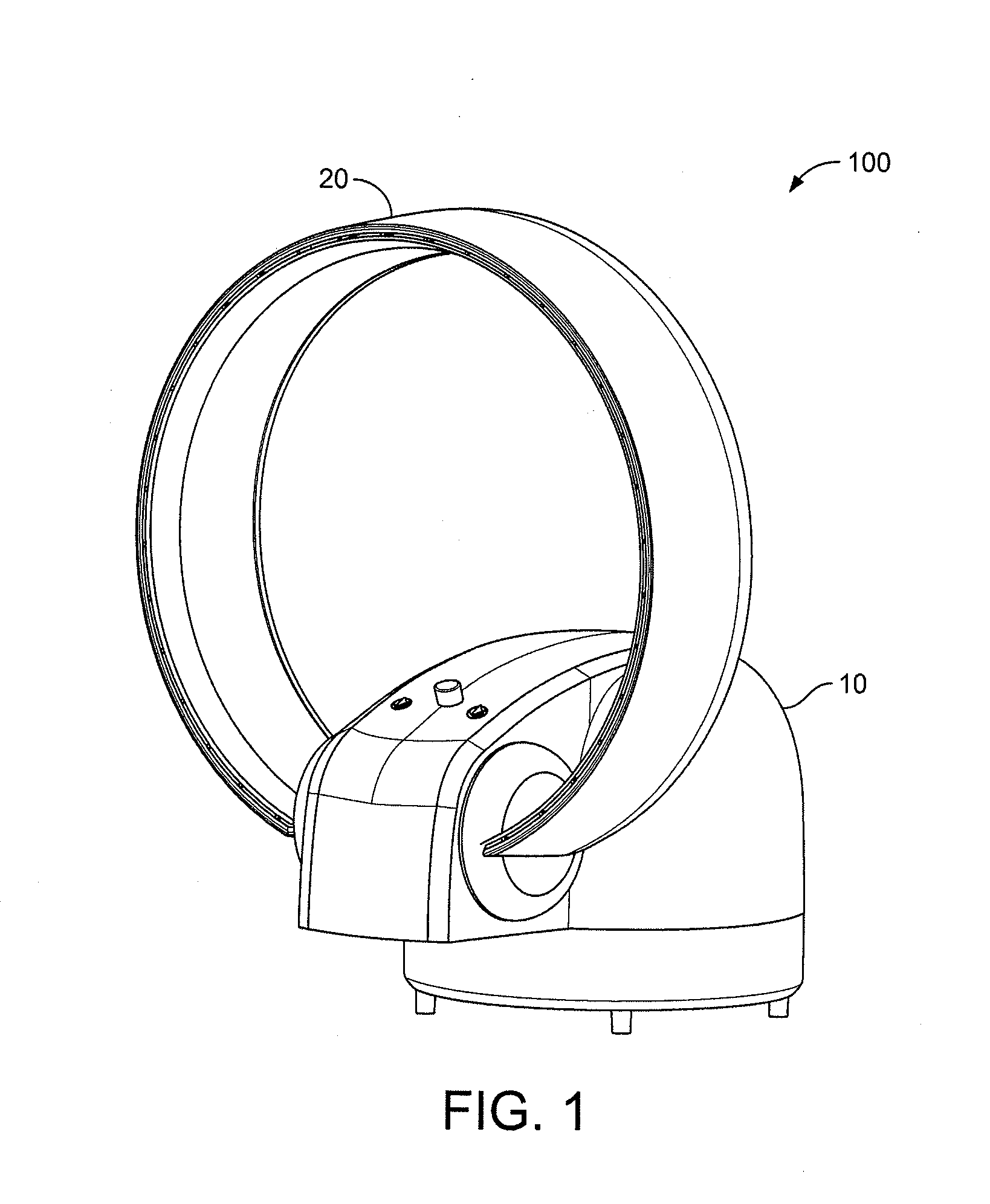

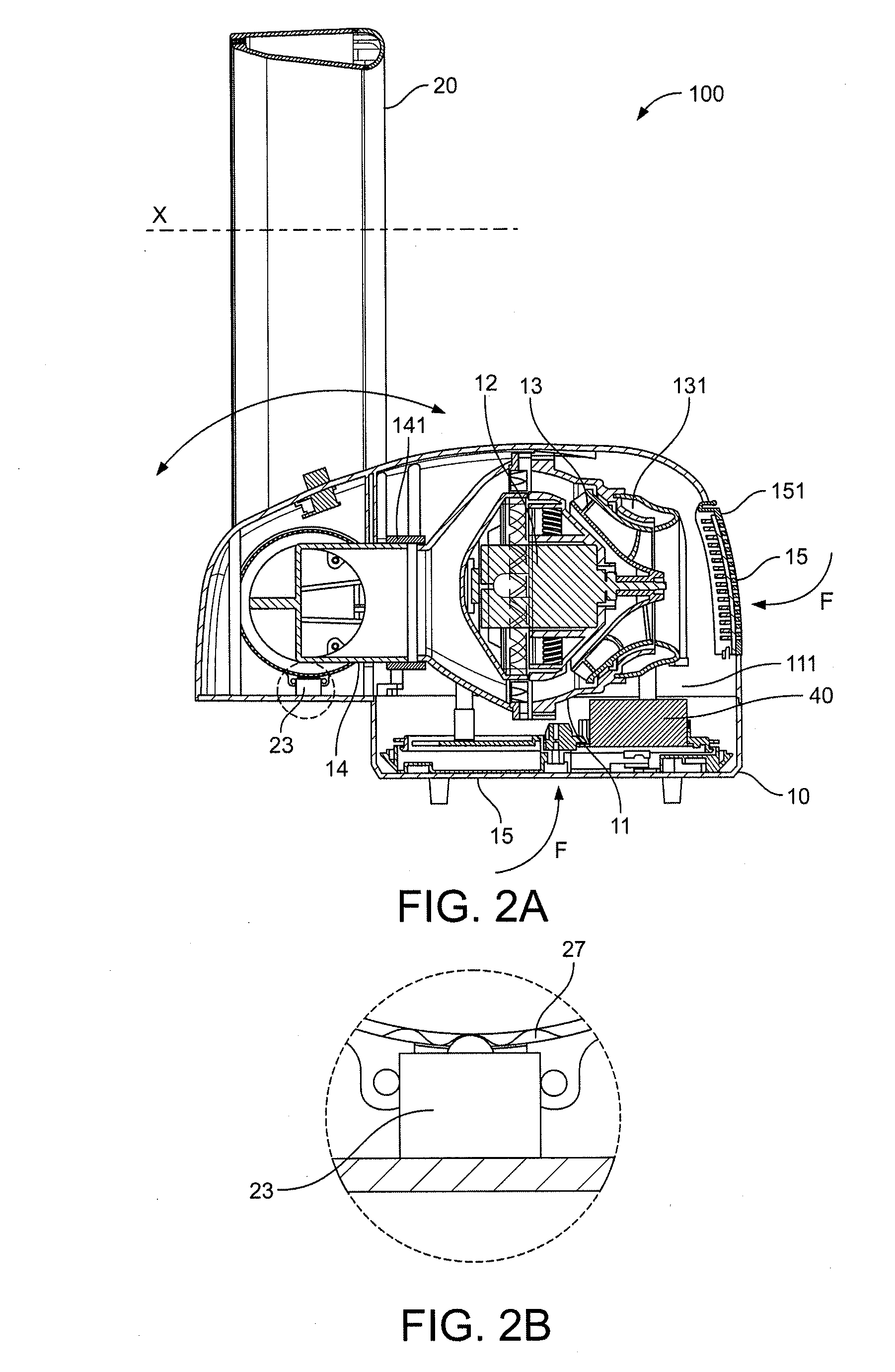

[0056]Referring to FIGS. 1-4, a device 100 for blowing air by means of a narrow slit nozzle assembly is provided. The device includes a base seat 10 for generating an air stream to supply air flow and a narrow slit nozzle assembly 20 supported by the base seat 10 for blowing air. An airflow passage is connected between the base seat 10 and the nozzle assembly 20. An intake end of the airflow passage is opened on the outer surface of the base seat 10, and an output end of the airflow passage is connected to the nozzle assembly 20 by means of a pivot component 21. An intake end of the nozzle assembly 20 is connected to an output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com