Method and System for Injecting Low Pressure Oxygen from an Ion Transport Membrane into an Ambient or Super Ambient Pressure Oxygen-Consuming Process

a technology of ion transport membrane and oxygen-consuming process, which is applied in the direction of manufacturing tools, lighting and heating apparatus, combustion types, etc., can solve the problems of high energy consumption of separation process, large increase in cost of oxygen (for use in oxy-fuel combustion), and high cost of glass melting furna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

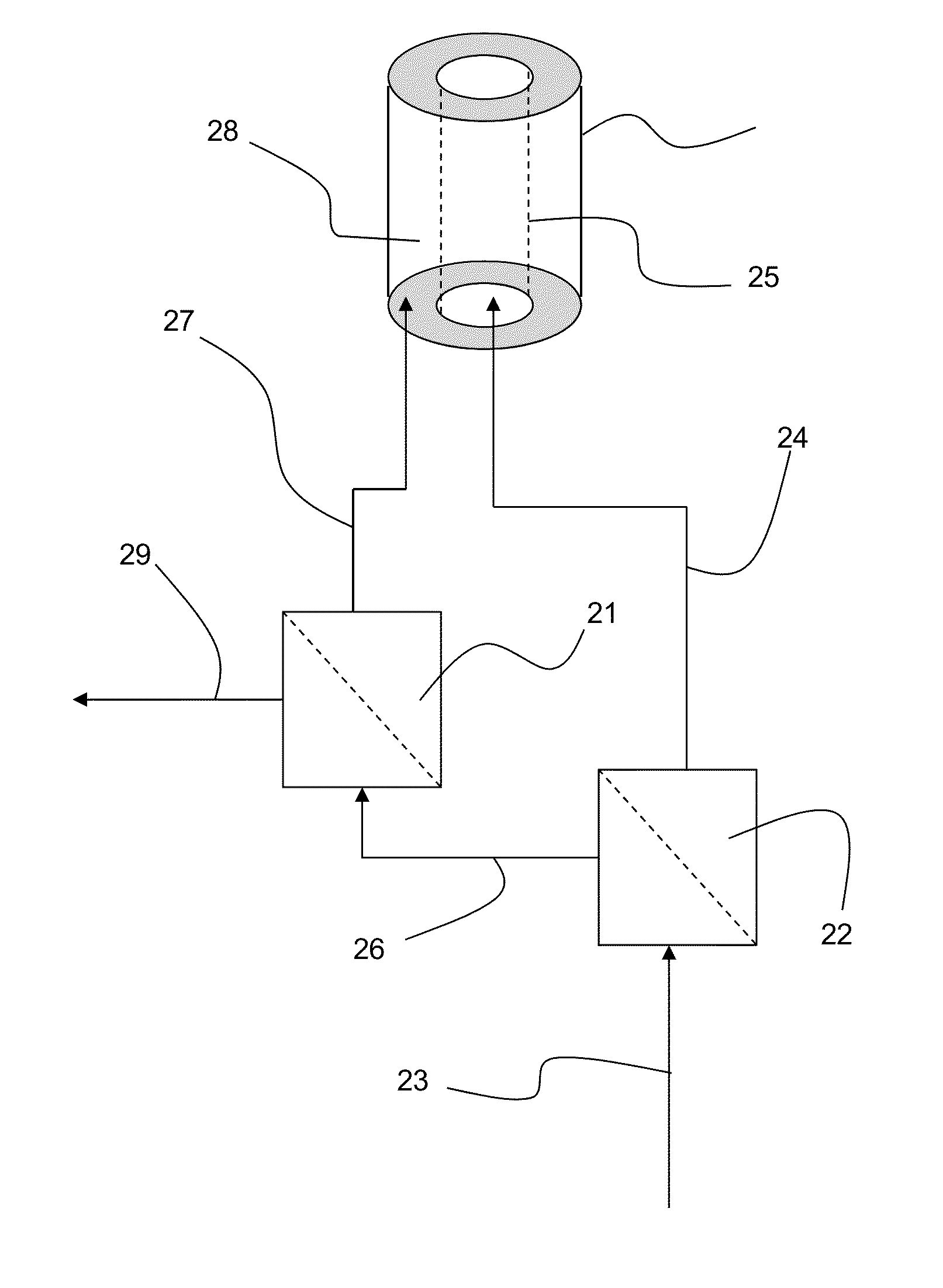

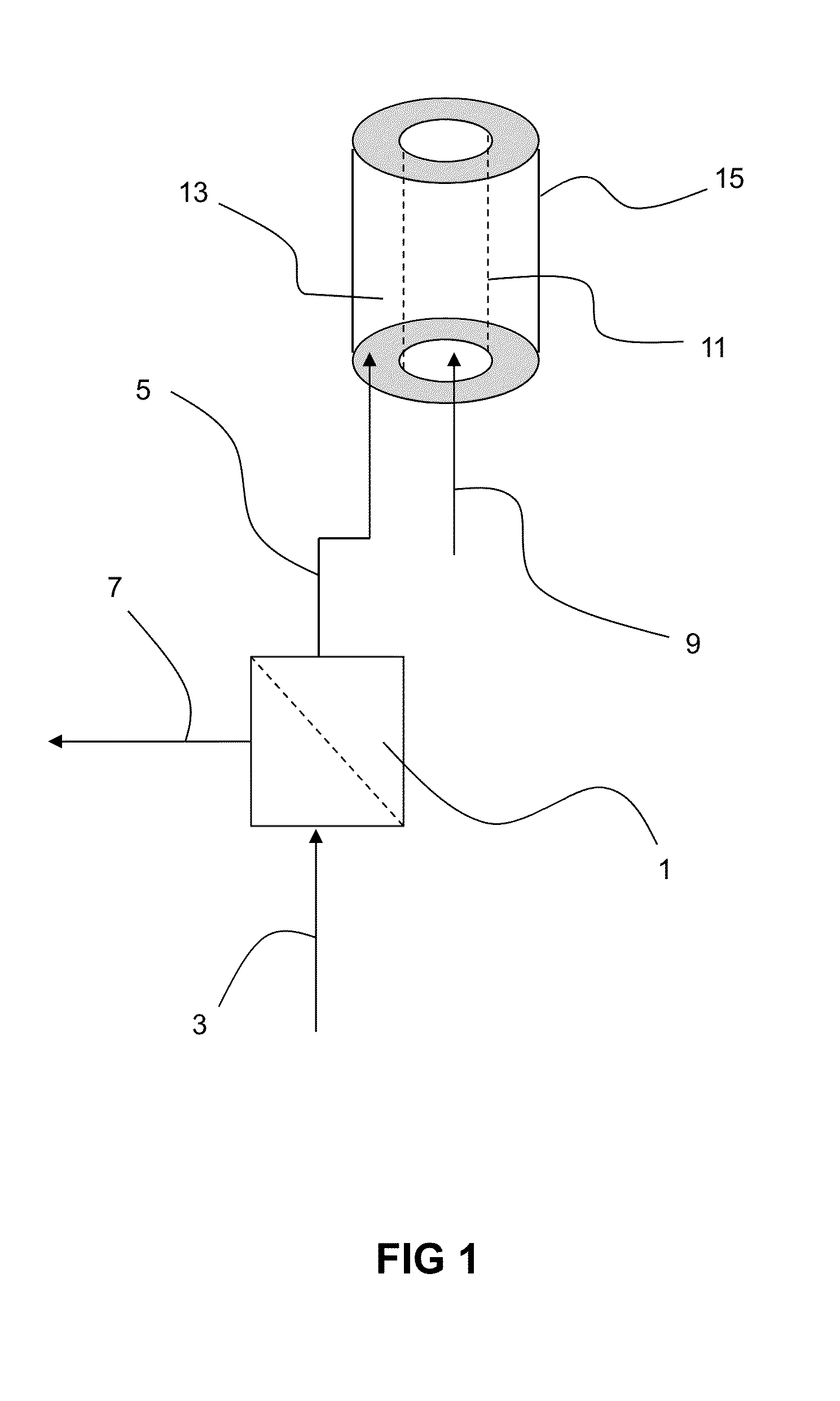

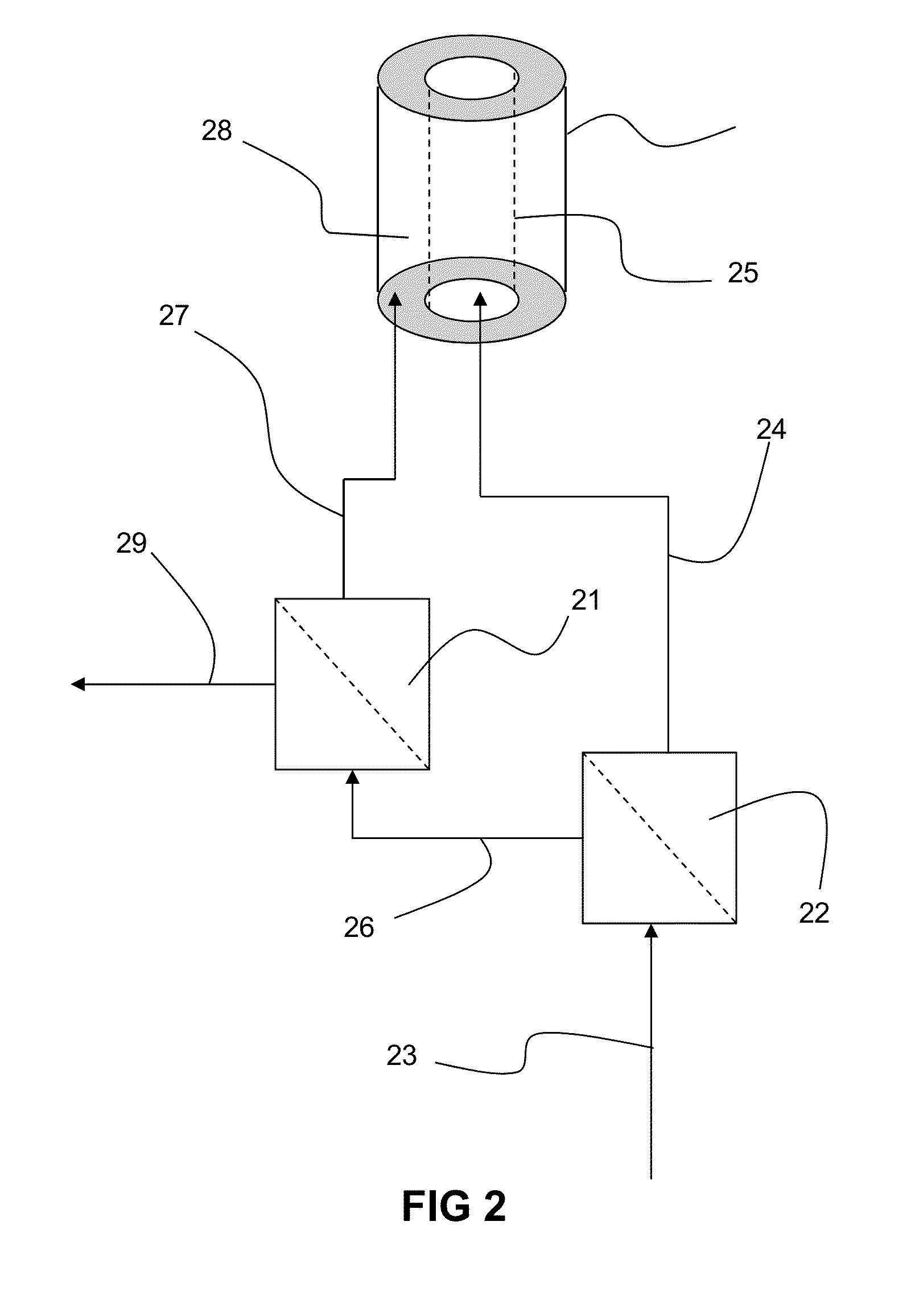

[0052]In this invention, sub ambient pressure oxygen that is permeated from an ion transport membrane is injected into an oxygen-consuming process from an oxygen injection device. The oxygen injection device comprises an outer tube concentrically disposed around an inner tube. The outlet of the inner tube and an outlet of an annular space in between the inner and outer tubes feed into an interior of a reactor in which the oxygen-consuming process takes place. A high velocity gas is injected into the reactor from the inner tube. Expansion of the high velocity gas at the outlet of the inner tube causes oxygen to be sucked from the annular space and, hence, sucked from the ion transport membrane.

[0053]The reactor containing the oxygen-consuming process is not limited. Typical types of reactors include oxy-combustion furnaces, oxy-combustion boilers, aluminum furnaces, cement kilns, electric arc furnaces having oxygen lances or oxy-combustion burners, industrial melting furnaces, and bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com