Techniques for Metal Gate Work Function Engineering to Enable Multiple Threshold Voltage Nanowire FET Devices

a technology of nanowires and function engineering, applied in the field of gate work function engineering, can solve the problems of multiple threshold voltage (vt) devices, becomes extremely problematic, and requires a substantial amount of process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

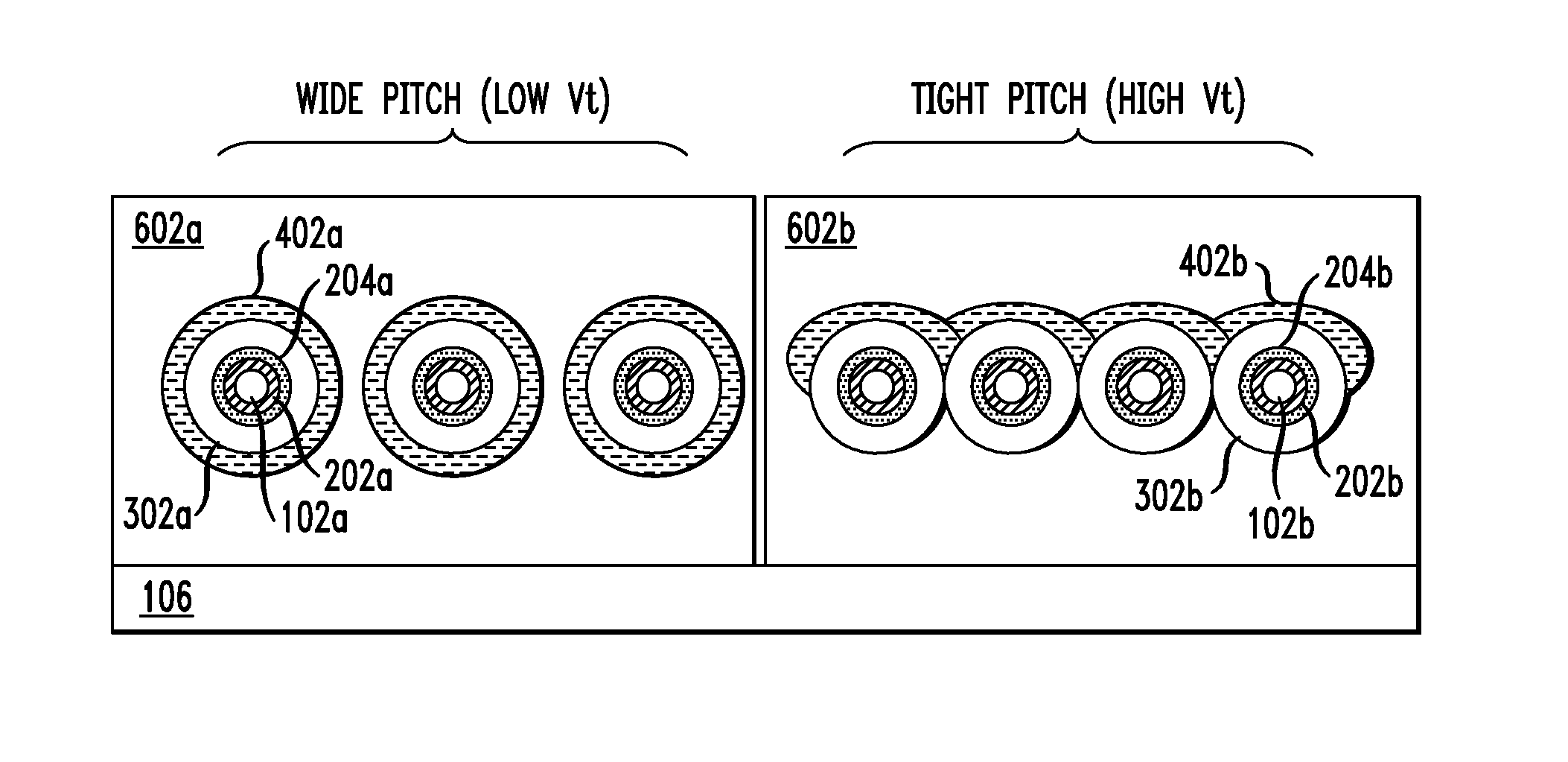

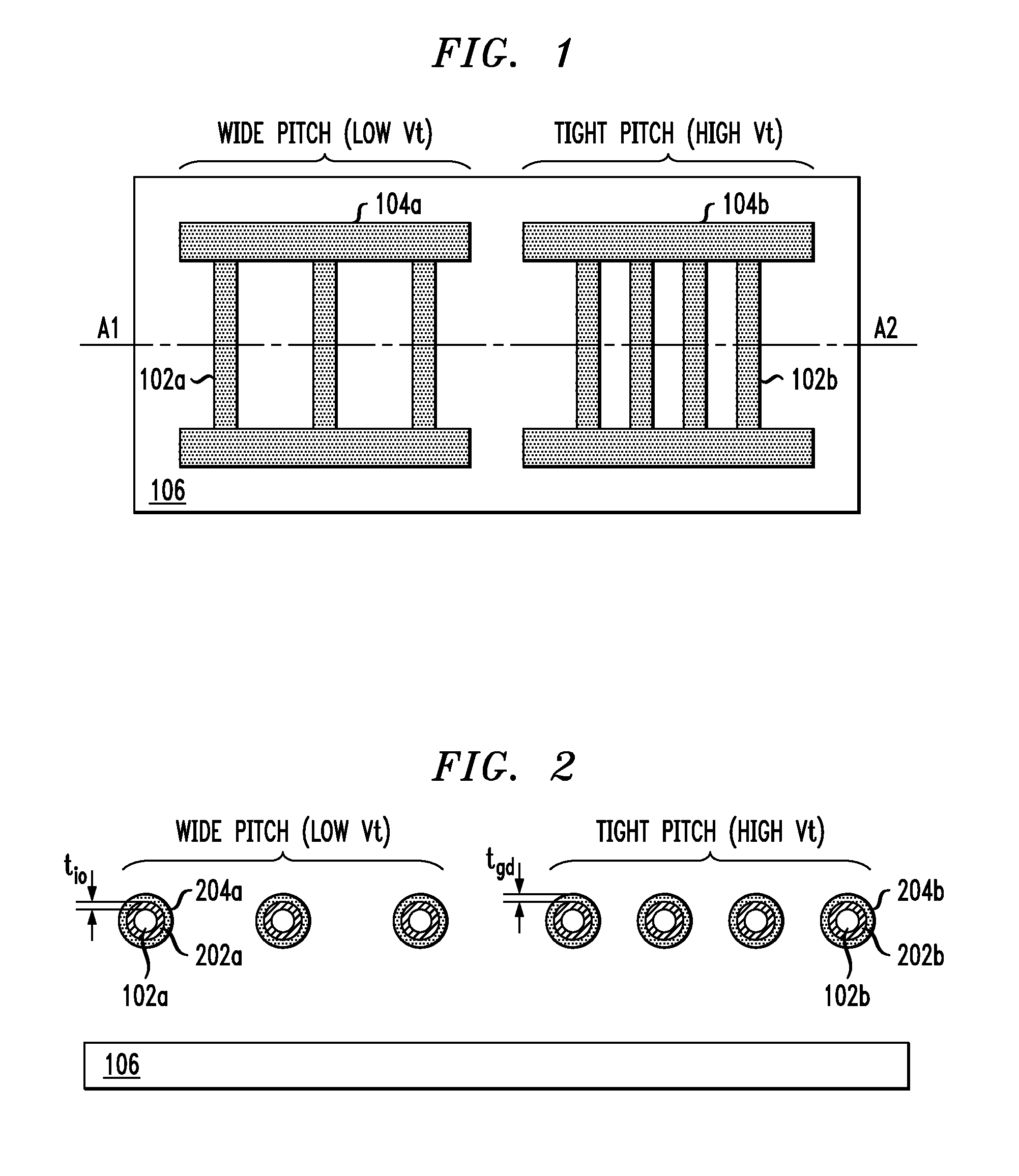

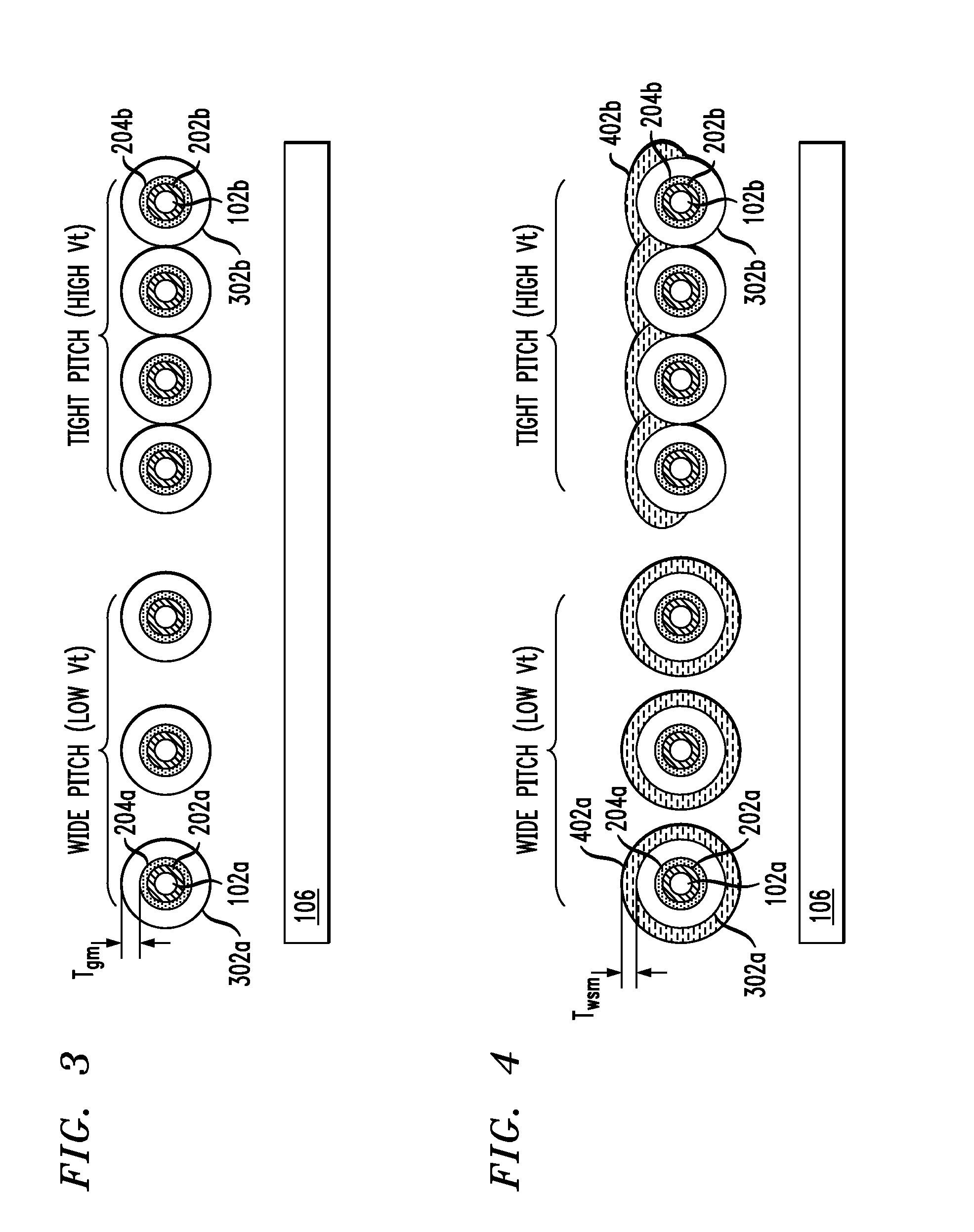

[0017]As described above, there are notable disadvantages associated with using doping and / or different work function gate stacks to produce multiple threshold voltage (Vt) nanowire field-effect transistor (FET) devices. Advantageously, provided herein are techniques for producing multiple Vt nanowire FET devices using a work function setting material in an amount that is modulated as a function of nanowire pitch (wire to wire pitch, where the pitch is defined as the distance from the center of one nanowire to the adjacent nanowire(s)). Namely, a thickness of the materials in the device gate stacks will be chosen such that less work function setting material ends up in the tighter pitch nanowire FETs. Thus, for smaller pitch, higher nanowire FET Vt is obtained and therefore, through nanowire pitch variation, different Vt devices may be fabricated. The technique does come at the cost of significant reduction in active width density, however if the lower Vt (wider pitch) devices are n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com