Anodizing device, continuous anodizing device, and film forming method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084]Hereinafter, the anodizing device, the continuous anodizing device, and the film forming method of the present invention will be described in detail by using drawings.

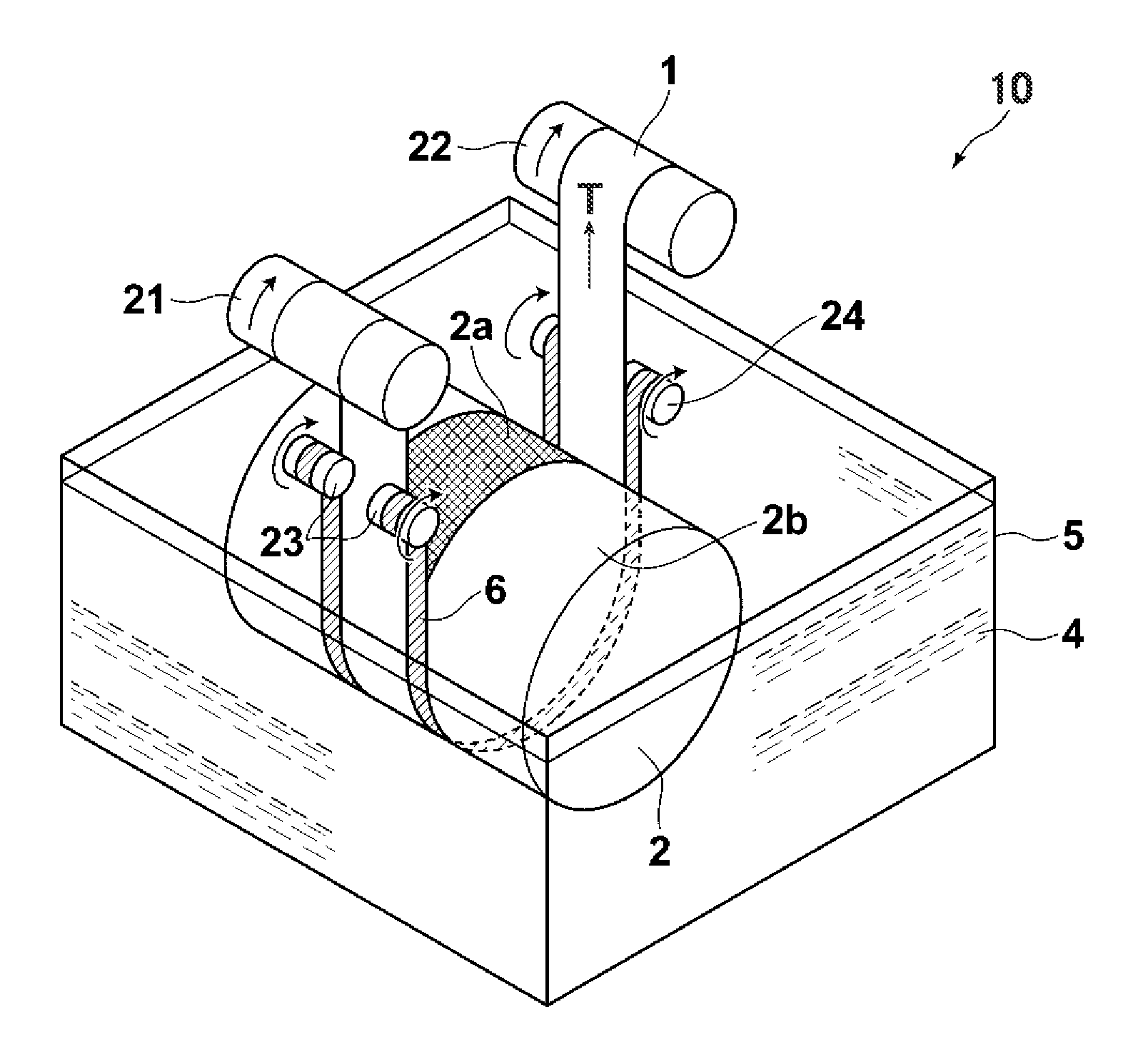

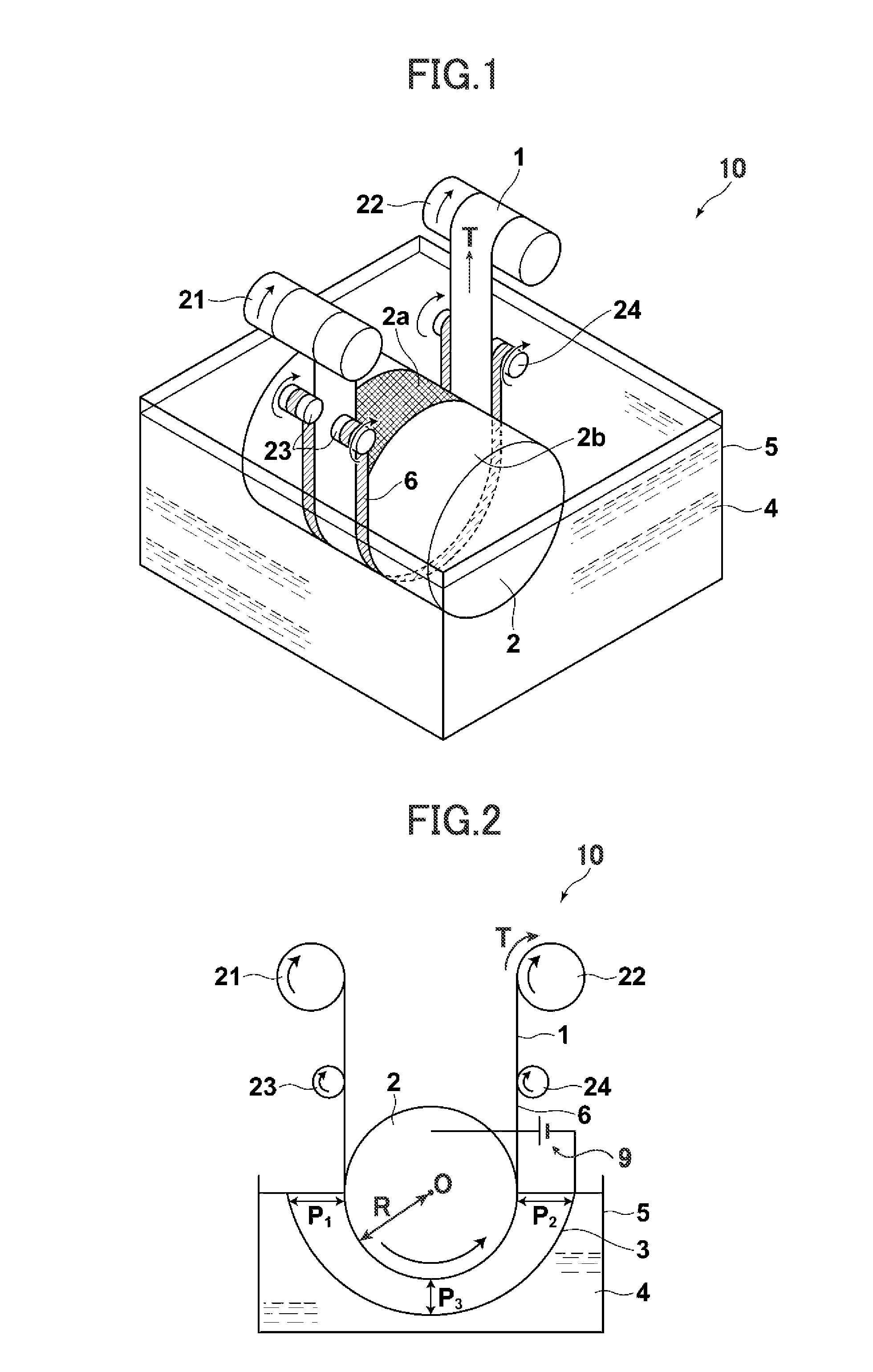

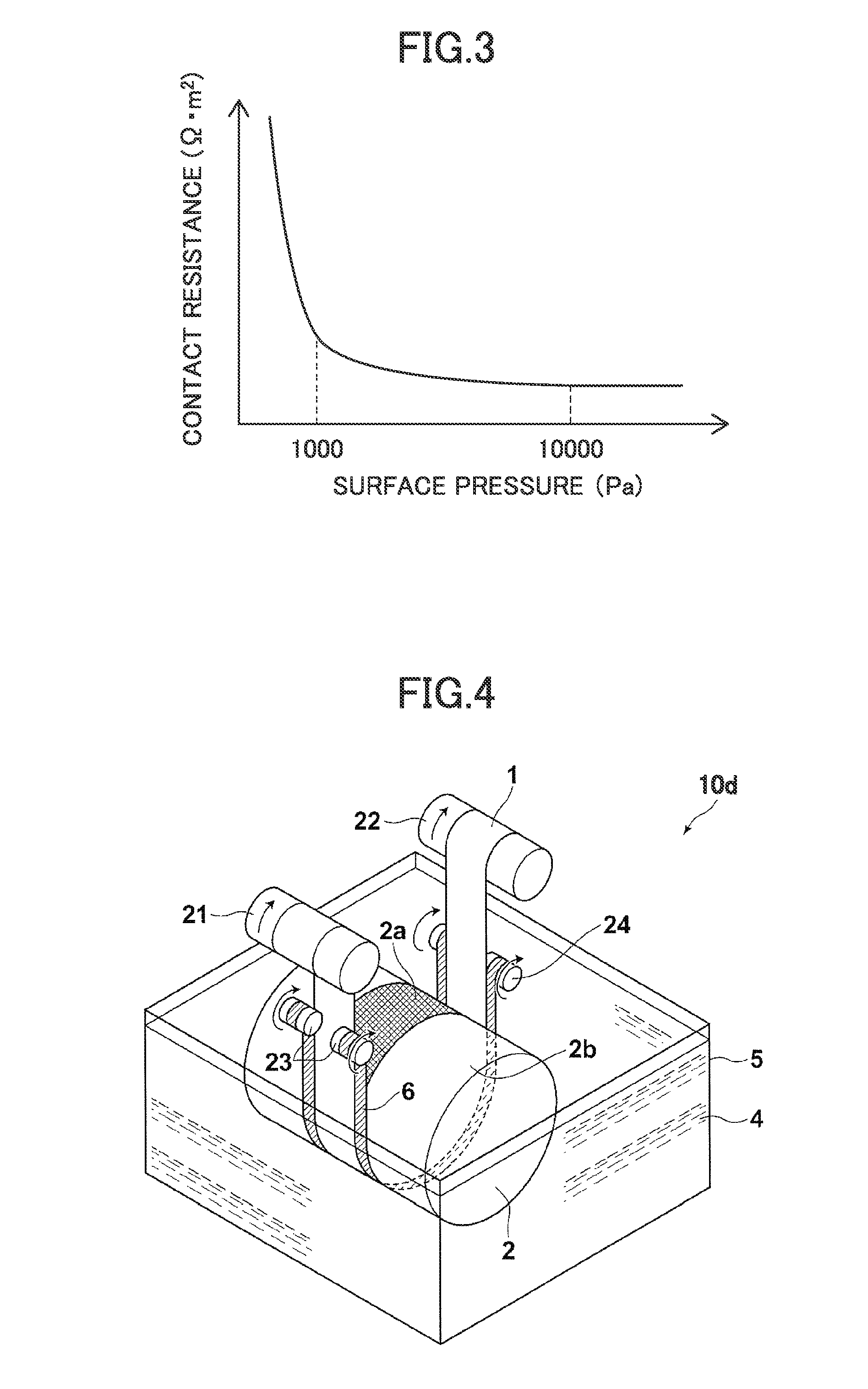

[0085]FIG. 1 is a schematic perspective view showing an anodizing device of an embodiment for achieving a first object of the present invention, and FIG. 2 is a schematic cross-sectional view of the anodizing device of the embodiment for achieving the first object that is shown in FIG. 1.

[0086]Hereinafter, the anodizing device used in common for achieving the first to fourth objects of the present invention will be described.

[0087]As shown in FIGS. 1 and 2, an anodizing device 10 of the present invention has a power supply drum 2 which is in close contact with and supports a web made of an anodizable metal or a web 1 made of composite conductive metal foil of which at least one surface is composed of an anodizable metal (hereinafter, also called simply “web 1”), and in which at least a portion 2a that is in close...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com