Oxygen diffusive wound dressings and methods of manufacturing and use

a technology of diffusive wound dressing and oxygen, which is applied in the field of wound dressing apparatus, can solve the problems of occlusion of open interfilament space and diminution of lateral oxygen diffusion along the length of the fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

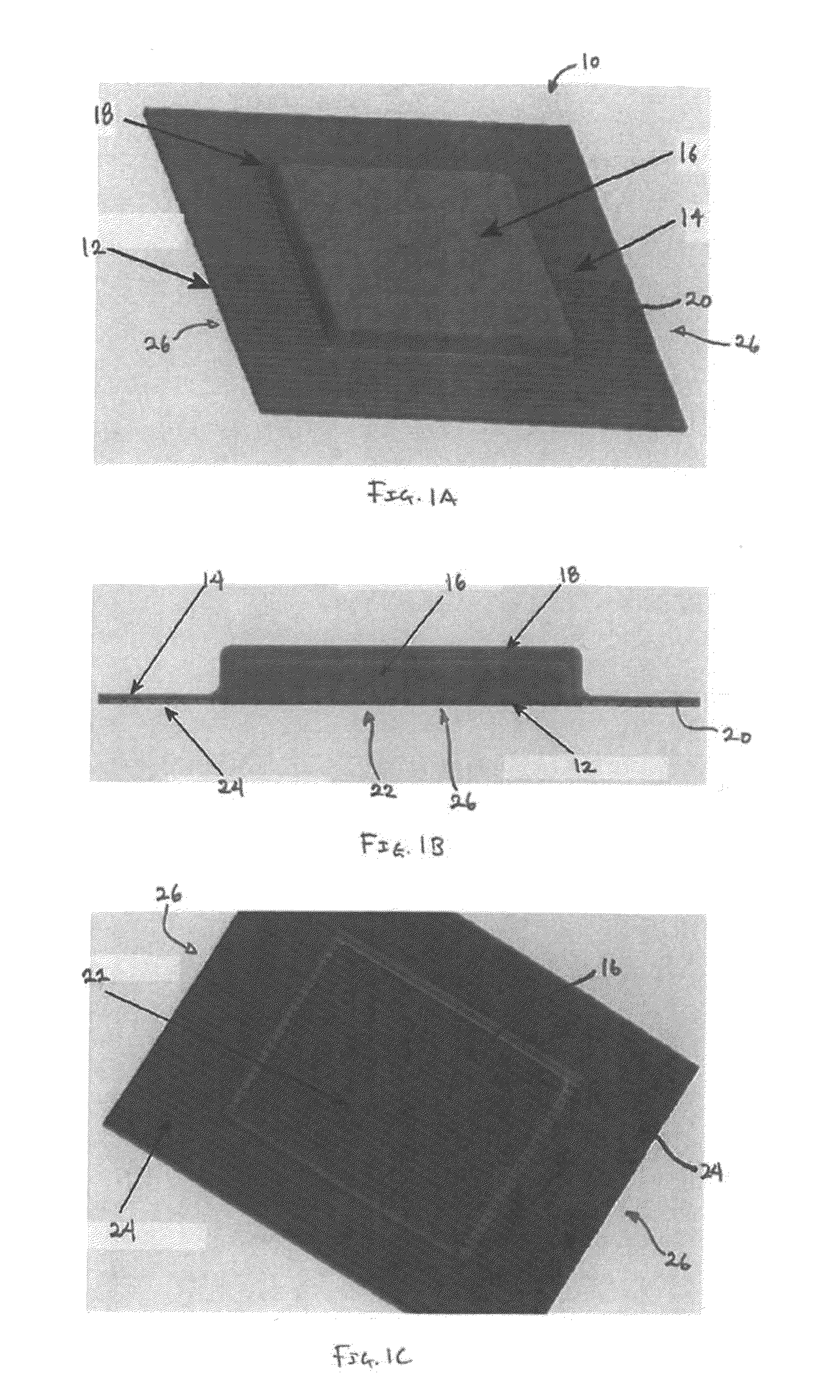

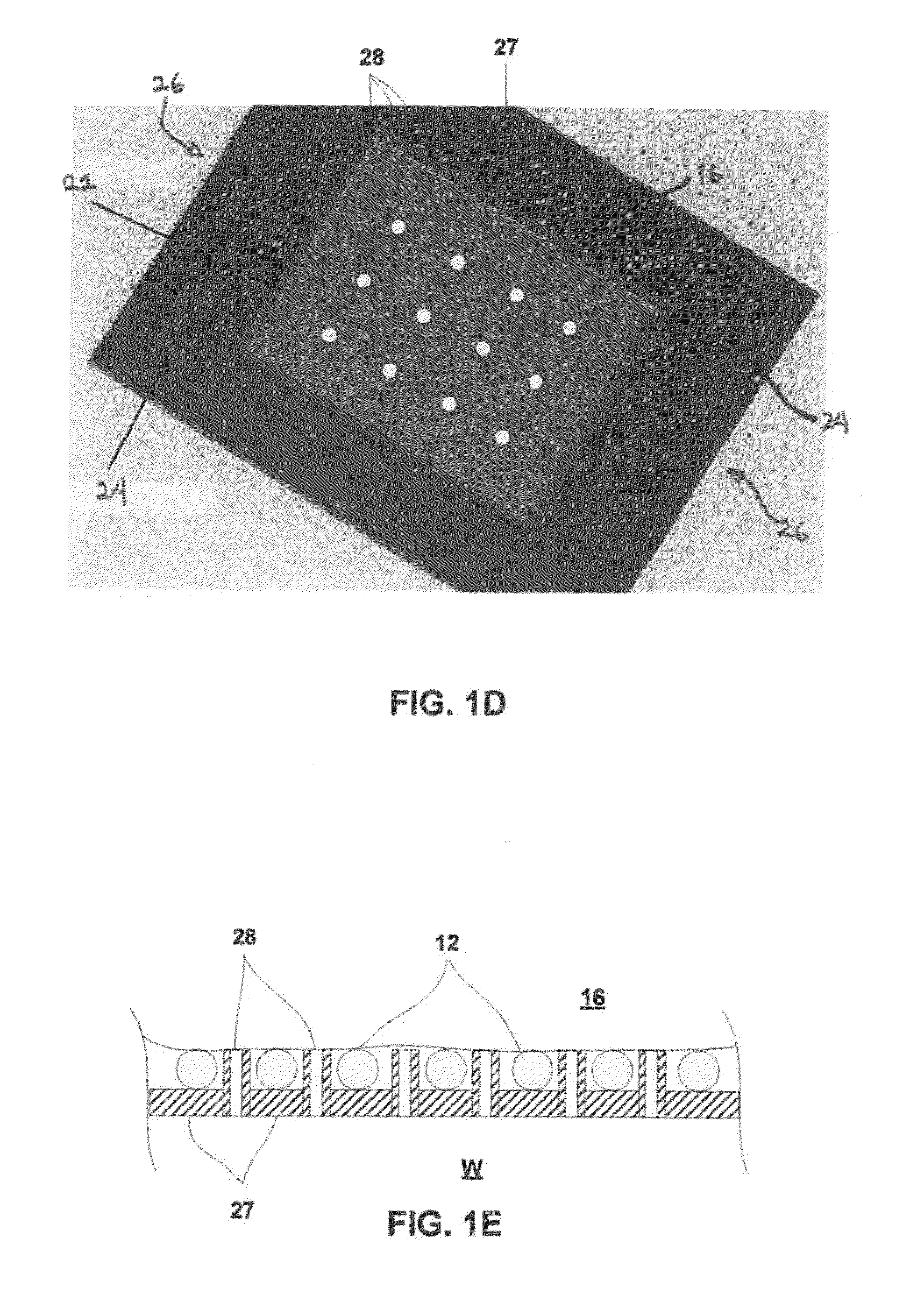

[0056]In covering wounds to facilitate healing, wound dressings are provided which maintain a high availability of oxygen, provide for removal of exudate, prevent toxin accumulation, minimize evaporation, and maintain a moist environment. Furthermore, all wound dressings should prevent contamination, inhibit infection and prevent re-injury of the healing wound. Such a wound dressing may also optionally allow for the administration of various agents or medicines directly to the wound site. Healing may thus be enhanced by providing conditions at the wound site with dressings which are conducive to cell survival and growth in the underlying tissue while preventing cells from dying. Because the wound dressing is sealed to prevent dehydration of the wound, the dressing may be entirely waterproof while preventing adhesion to the wound allowing for normal lifestyle activities including bathing and accelerating healing time.

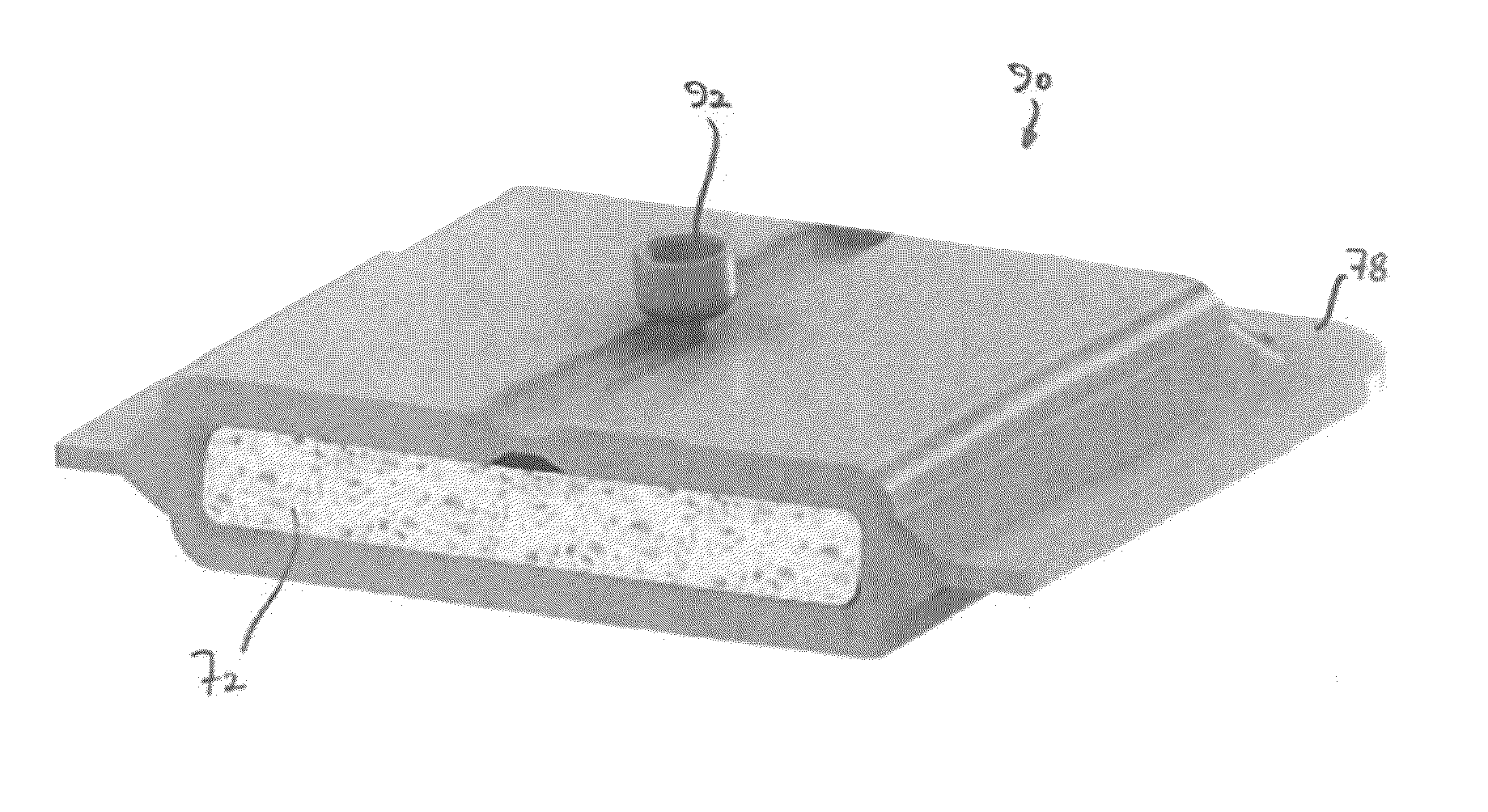

[0057]One variation for a wound dressing which provides for oxygena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com