Method and apparatus for the sterilization of ground meat using supercritical co2

a technology of supercritical co2 and ground meat, which is applied in the direction of meat/fish preservation using chemicals, milk preservation, food preparation, etc., can solve the problems of meat being too expensive, losing vital taste and texture characteristics, unsightly or exposed to unwanted irradiation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The detailed embodiment of the present invention is disclosed herein. It should be understood, however, that the disclosed embodiment is merely exemplary of the invention, which may be embodied in various forms. Therefore, the details disclosed herein are not to be interpreted as limiting, but merely as a basis for teaching one skilled in the art how to make and / or use the invention.

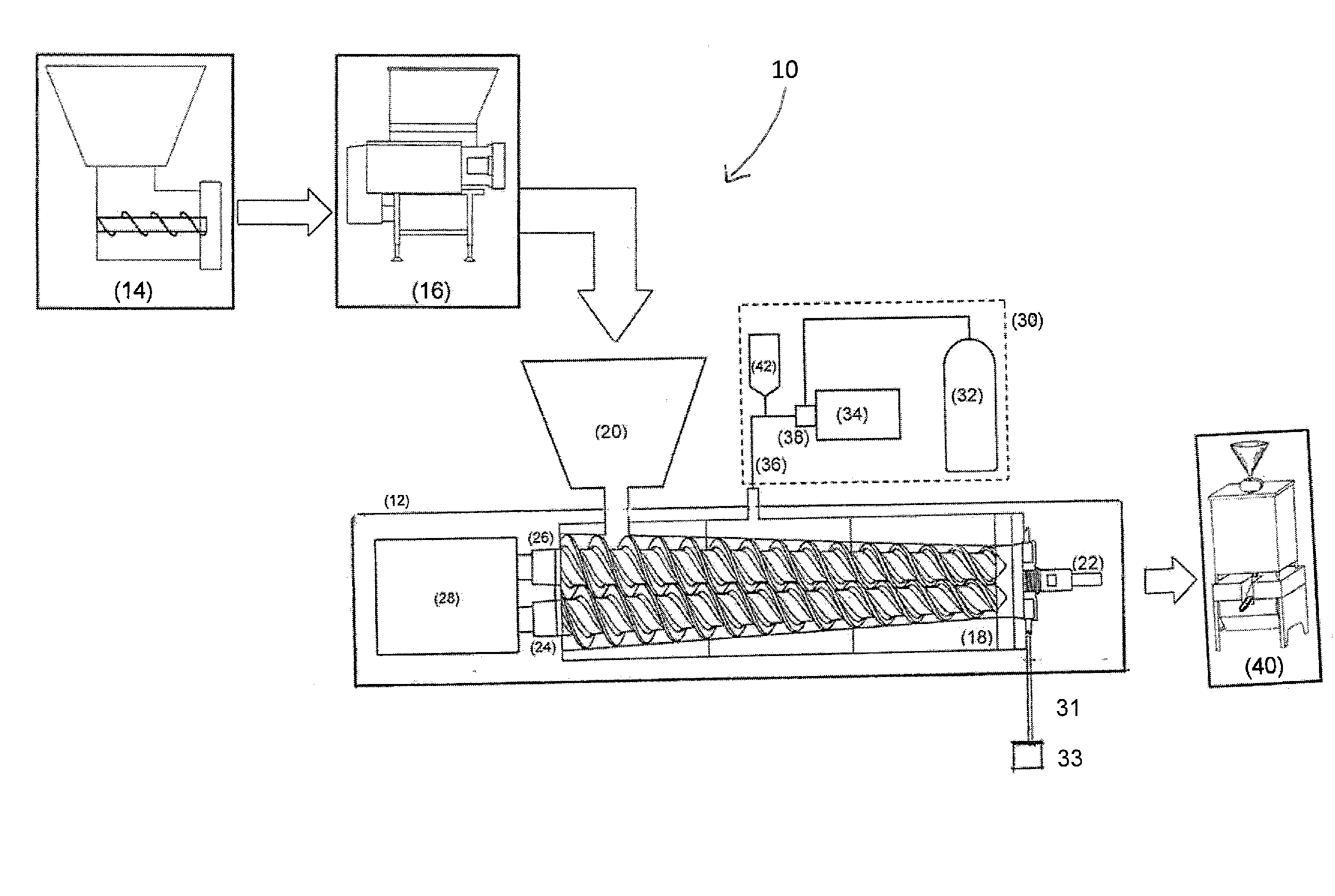

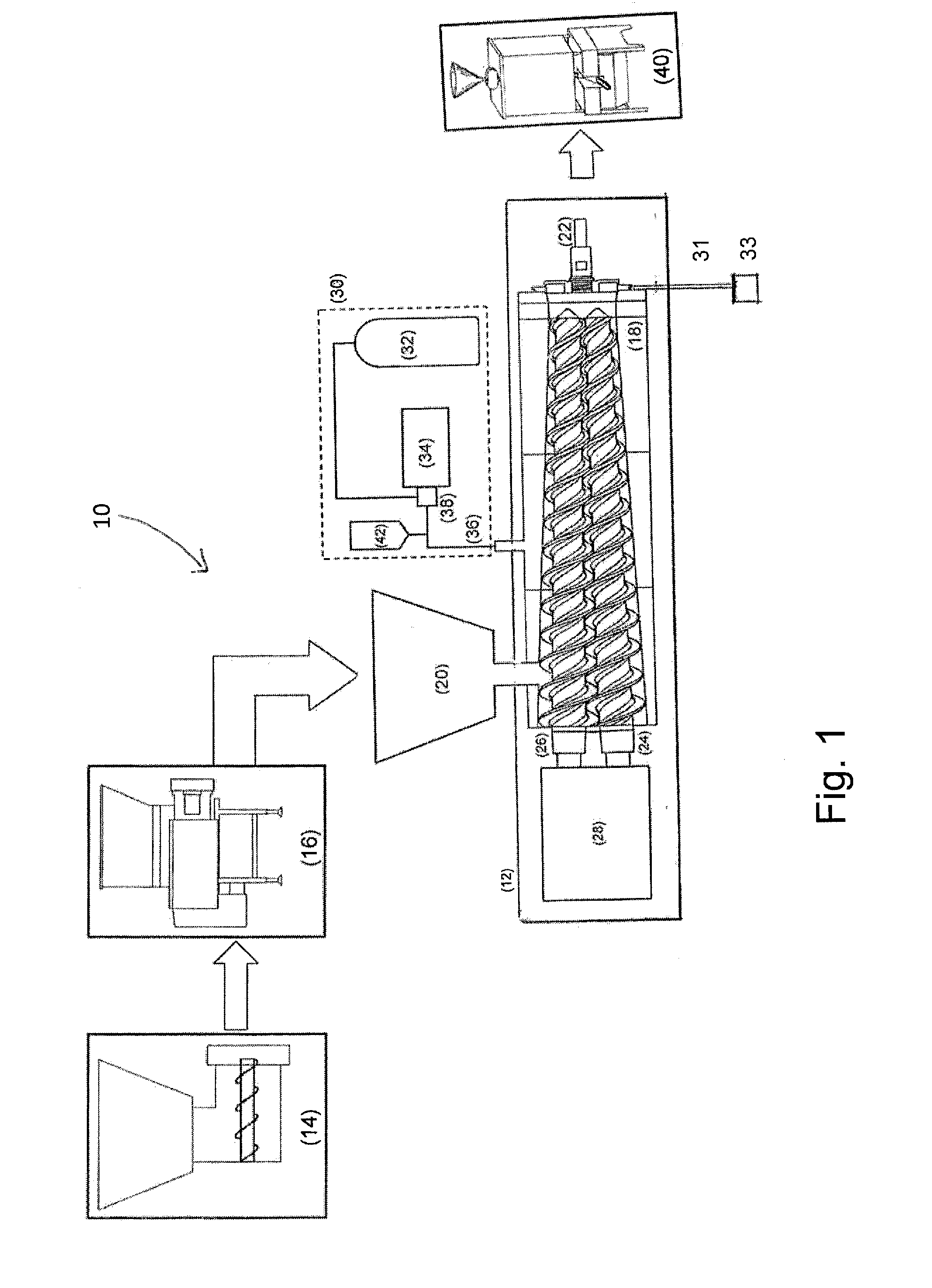

[0013]During the commercial processing of ground meat, the meat, after grinding, is commonly moved to packaging machinery under the control of an extrusion conveyance tube, referred to below as an extruder. While the meat is moving through the extruder at a controlled rate, the temperature and pressure within the extruder can be controlled. In accordance with the present invention, the ground meat is treated with supercritical CO2 as it passes through the extruder. The treatment of the ground meat with supercritical CO2 results in complete sterilization of the ground meat before it is packaged.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com