Roof-greening sheet

a technology of green roof and sheet, applied in the field of sheets, can solve the problems of deterioration of the root barrier function and inability to provide a good root barrier function, and achieve the effects of enhancing thermal insulation, reducing thermal conductivity, and increasing the lifetime of the sheet and the building structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]According to the feature of the present invention, in a sheet for green roof which is installed on the top of a waterproof layer to prevent the root growth of plants in vegetation of a green roof, the sheet for green roof includes a glass fabric having a predetermined thickness and a predetermined area, and a copper film having the same area of the glass fabric and being integrally laminated on both sides of the glass fabric using pressure.

[0021]Reference will be now made in detail to the preferred embodiment of the present invention with reference to the attached drawings.

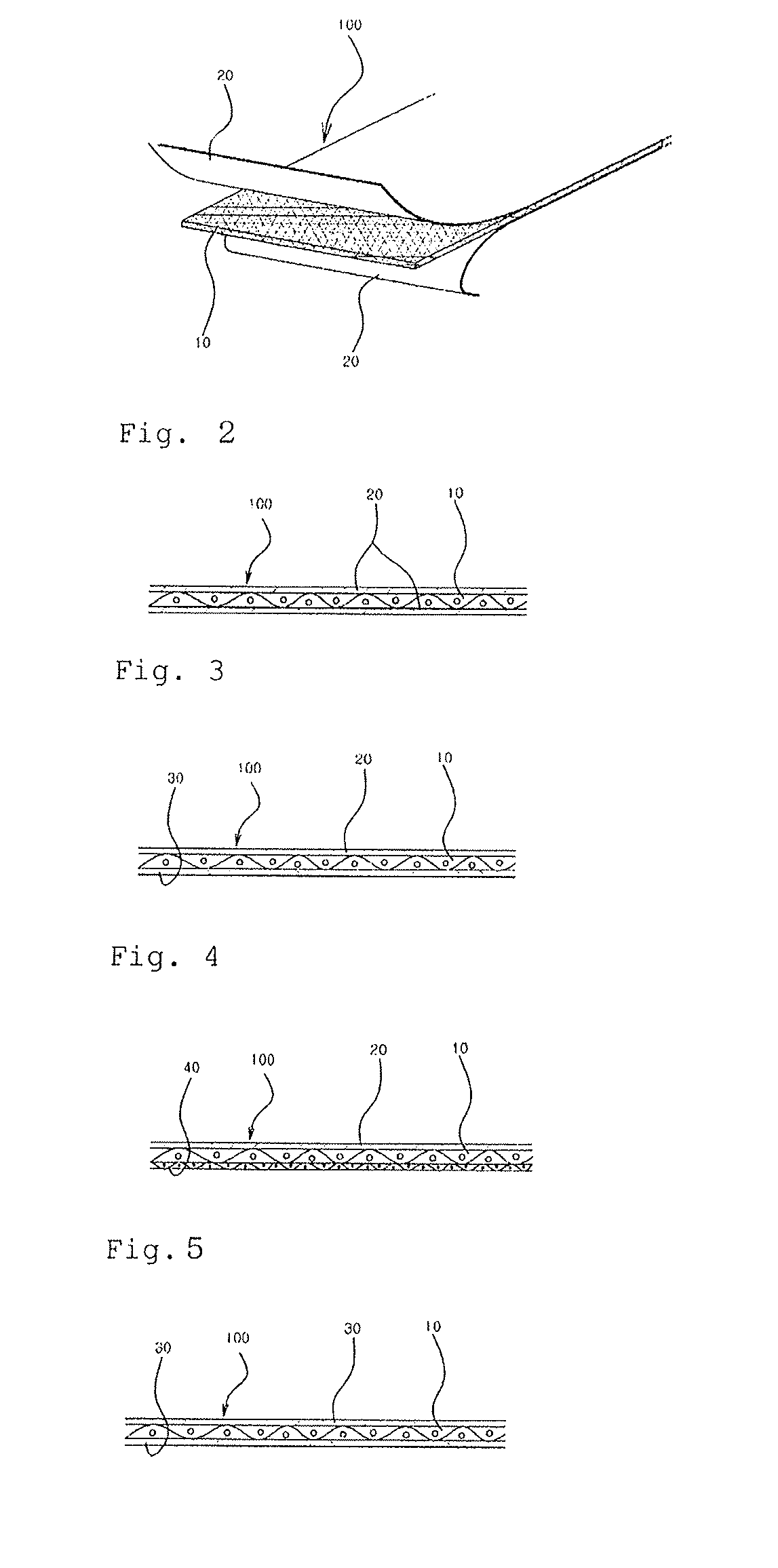

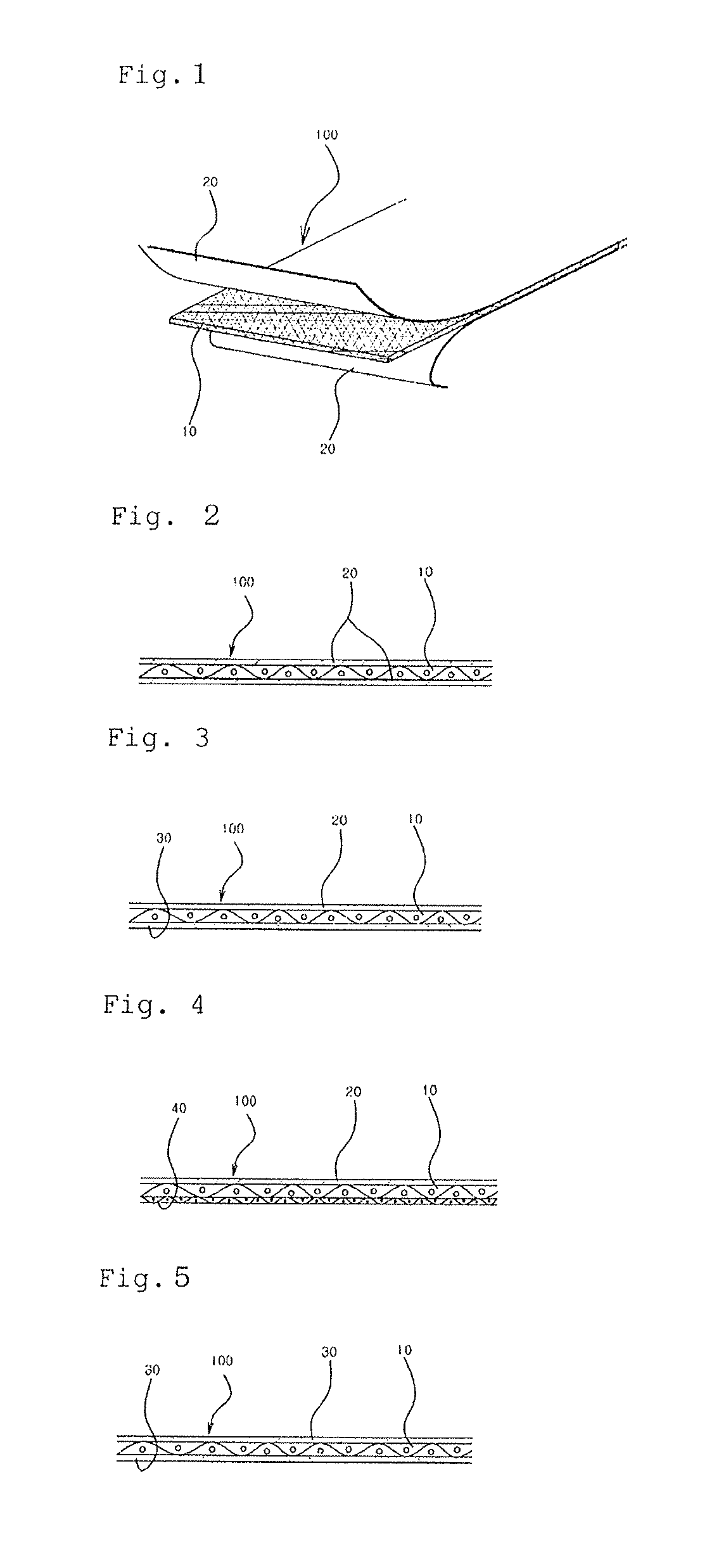

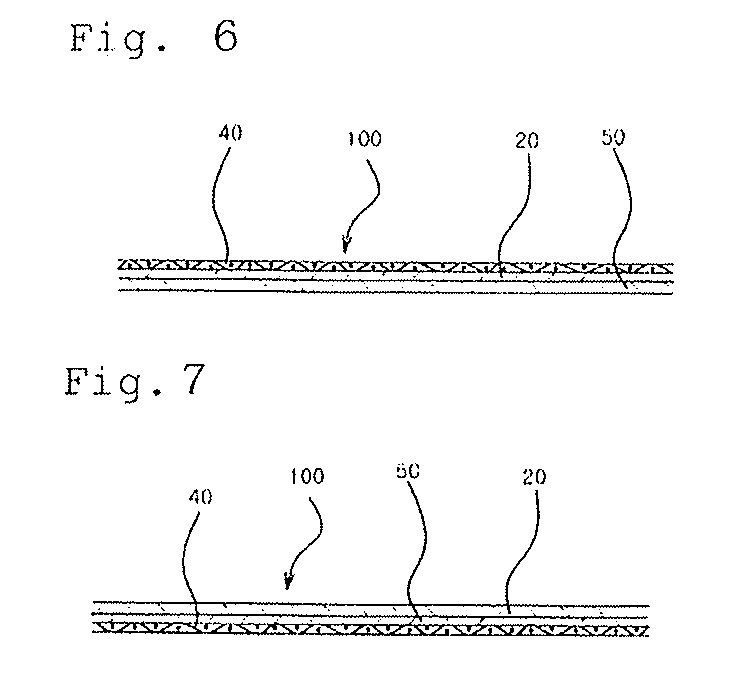

[0022]FIG. 1 is a schematic exploded perspective of a first embodiment of the present invention; and FIGS. 2 to 7 are enlarged cross-sections showing the first to sixth embodiments of the present invention, respectively.

[0023]As illustrated in the figures, a sheet 100 for green roof according to the present invention comprises a glass fabric 10, a copper film 20, an aluminum thin film 30, a nonwoven fabric 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com