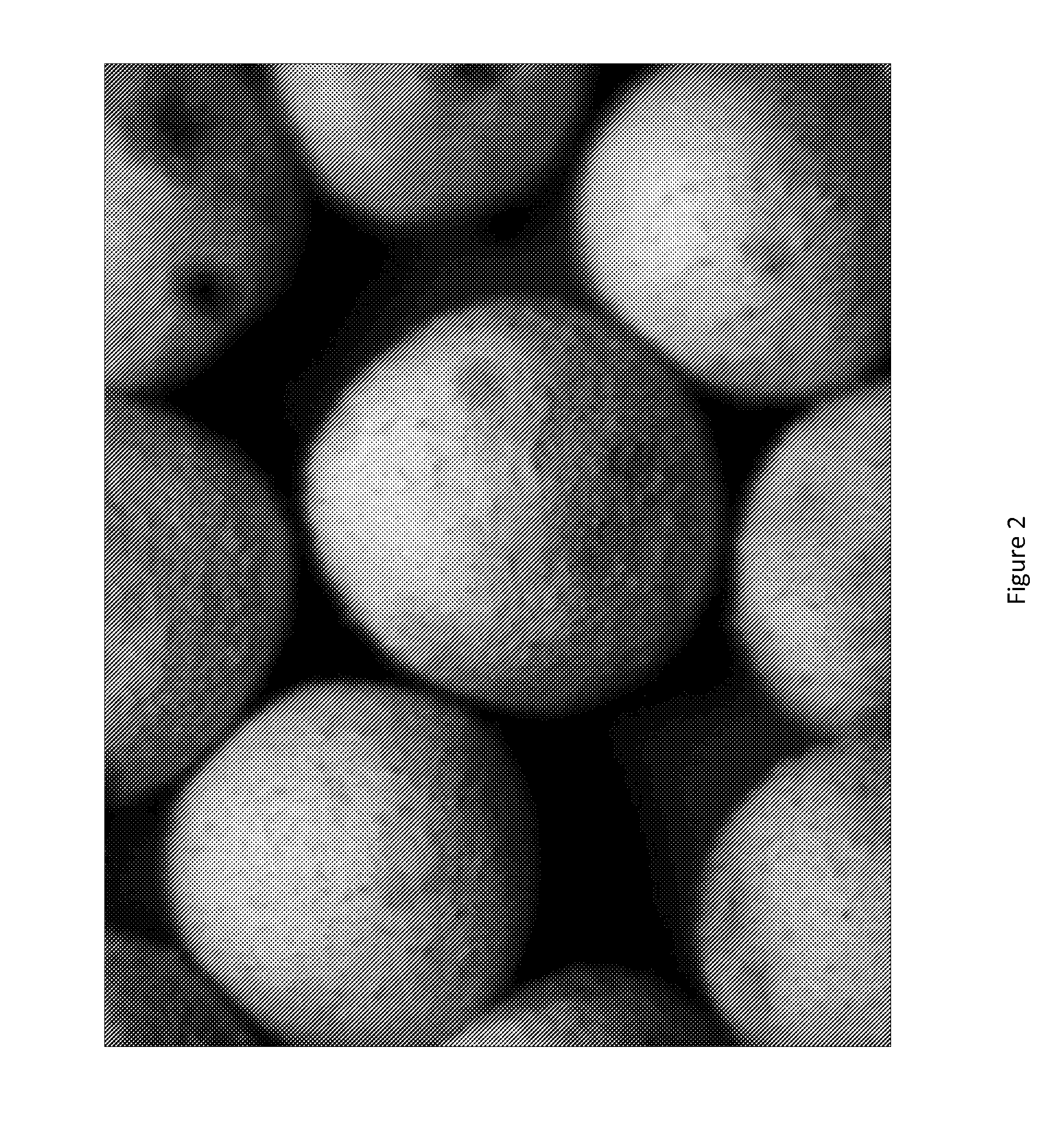

Spherical pellets containing common clay particulate material useful as a proppant in hydraulic fracturing of oil and gas wells

a technology of clay particulate material and spherical pellets, which is applied in the direction of sealing/packing, other domestic articles, and borehole/well accessories, etc., can solve the problems of high transportation cost of said proppants, difficulty in manufacturing process, and inability to use ceramic proppants as commonly, so as to achieve more efficient and cost-effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples i-iv

[0059]For Example III, a dry ceramic mix of:[0060]4,400 grams of common red clay obtained from Brown County, Texas deposit (“BCH”); and[0061]1,100 grams of three aluminosilicate network modifiers;

were blended for two minutes in the pan of a mixer / granulator (may use Eirich Machines, Inc., Model RV02) with the cylindrical container rotating at about 30 hertz. The pan and rotor were engaged with a fast pan speed and a rotor speed of 40 hertz. Pan rotation was clockwise and rotor rotation was counter-clockwise. The impacting rotor impeller had vanes or deflecting blades of two sizes, 125 mm and 185 mm long. A mixture of 700 grams of water and binder, selected from among cornstarch, CMC, or PVA, was added over a period of about one minute. Speed was increased, immediately after the water and binder were added, to 70 hertz. At 4 minutes, pan is reduced to slow speed and 250 grams of dry retained mixed material were added. At 5 minutes total mixing time, the rotor speed was decreased to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

| residence time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com