Integrated Processes for Purifying a Cellulosic Material

a cellulosic material and integrated technology, applied in pulp by-product recovery, pulp liquor regeneration, papermaking, etc., can solve the problems of high cost of such so-called cellulose produced in commercial pulp processes, incompatible with certain industrial uses, and inability to achieve dmdo. to achieve the effect of reducing the cost of dmdo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

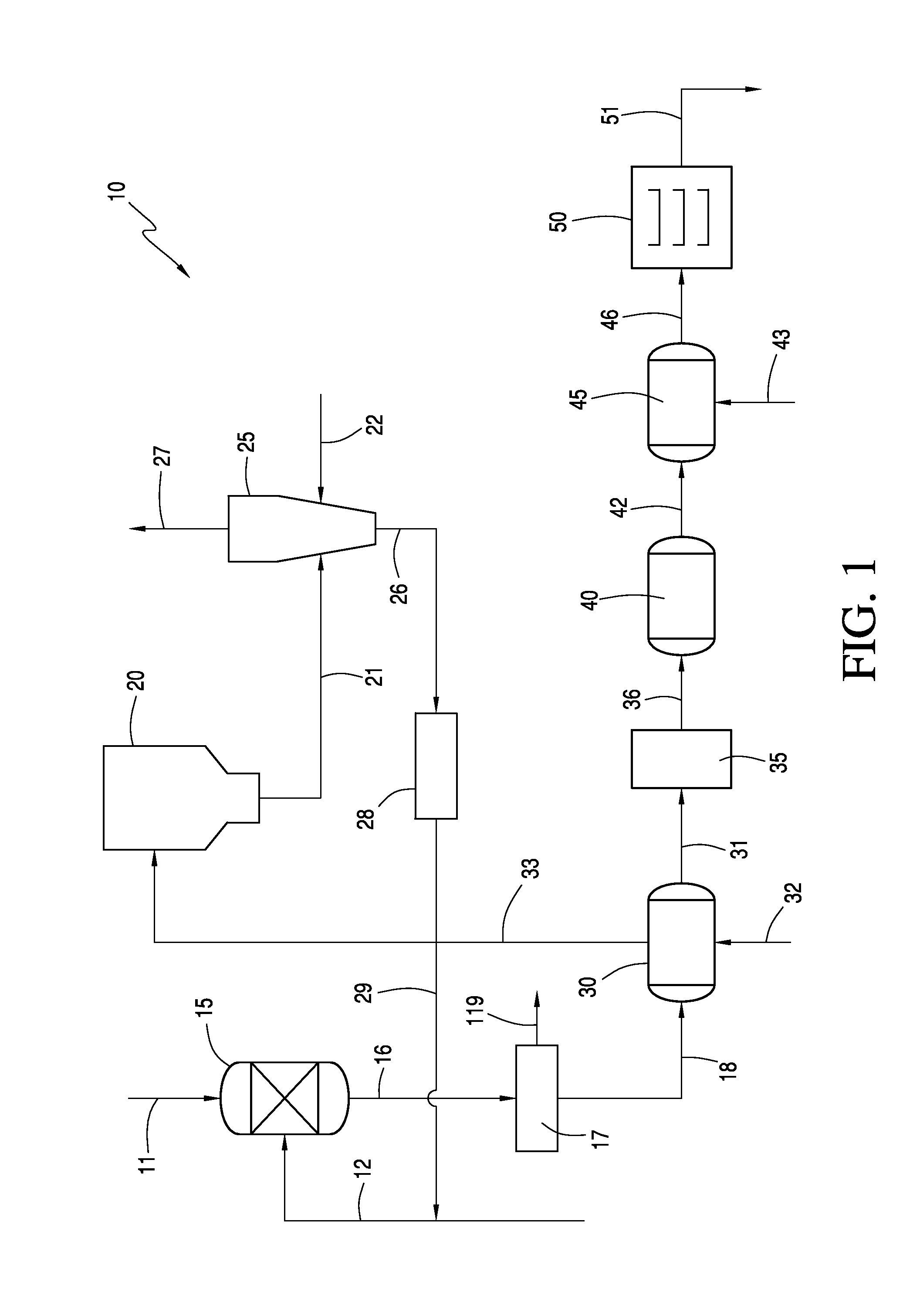

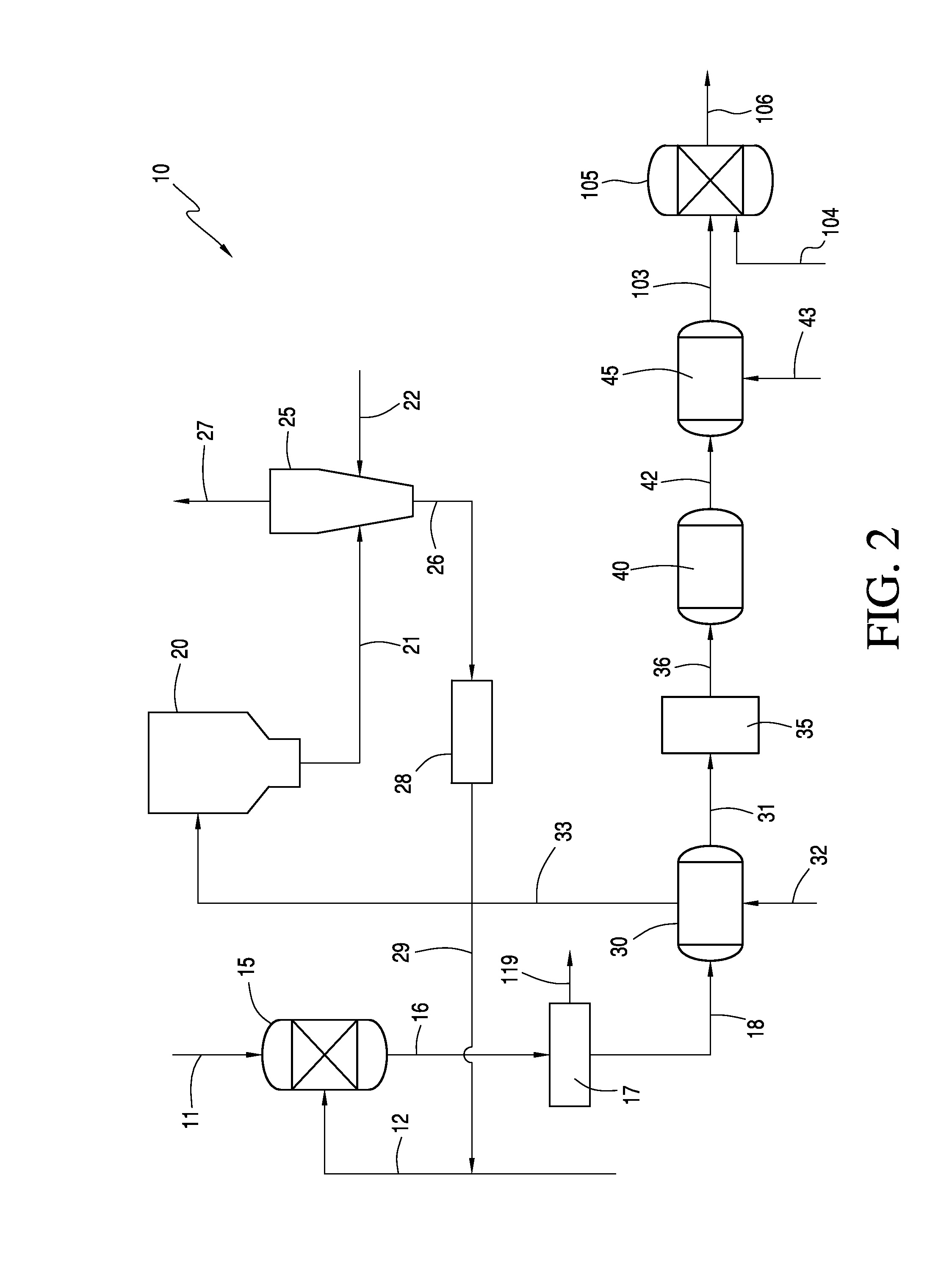

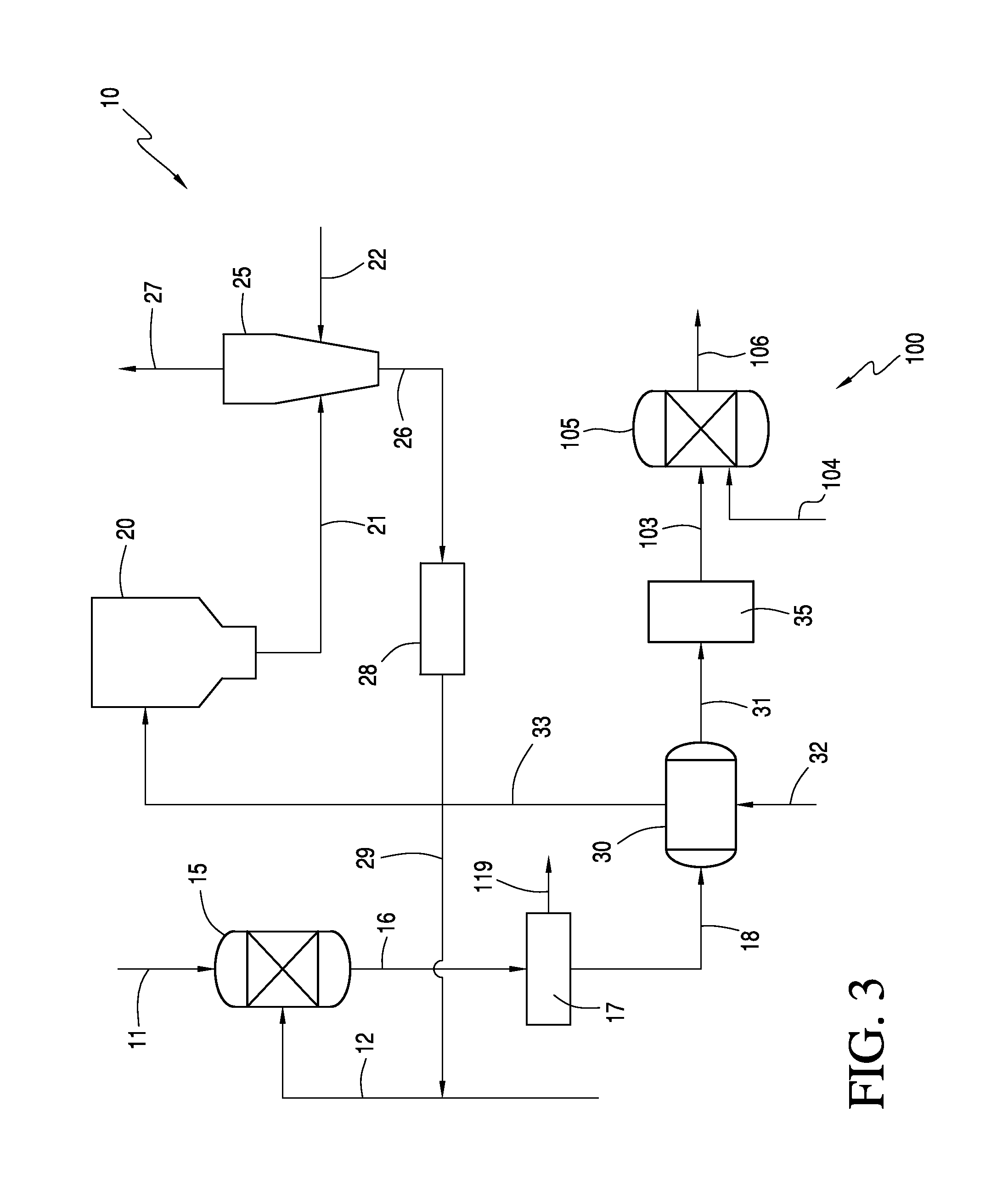

Method used

Image

Examples

example 1

[0159]A wet pulp, simulating a wet pulp from a kraft or sulfite pulping process, was pre-extraction washed with DMSO to reduce the water content. Excluding any DMSO from this pre-extraction wash, a pulp comprising 74.8 wt. % cellulose, 18.7 wt. % hemicellulose and 6.5 wt. % water was fed to an extraction unit. Separately, an extractant comprising 3.5 wt. % EMIM Ac and 96.5 wt. % DMSO was fed to the extraction unit. The extraction was conducted at a temperature of 90-110° C. and a pressure of 90-110 kPa. An extraction mixture comprising 3.6 wt. % cellulose, 0.89 wt. % hemicellulose, 0.31 wt. % water, 3.3 wt. % ionic liquid and 91.9 wt. % DMSO was removed from the extractor and sent through a vacuum filter and washed with an extractant wash to remove an extraction filtrate comprising extractant and hemicellulose. The extractant wash was water and was fed at a 10:1 mass ratio of water to pulp. The washed cellulosic material, e.g., the intermediate cellulosic material, comprised 24.5 wt...

example 2

[0162]The finished cellulosic product and the finished hemicellulose product were prepared as in Example 1, except that the extraction process was completed in 82-stage counter-current operation. The extraction time was dropped to 60 minutes at a temperature of 90° C. for dissolving the same amount of hemicellulose, which was indicated by the UV absorbance value of 1.2 at 277 nm wavelength, or equivalently 2.8 wt. % hemicellulose.

example 3

[0163]The finished cellulosic product and the finished hemicellulose product were prepared as in Example 1, except that the extractant wash comprised 90 wt. % acetic acid and 10 wt. % water. The value of UV absorbance at 277 nm for the final pulp is 0.98, or equivalently 1.9 wt % hemicellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com