Low-temperature gas supply device, heat transfer medium-cooling device, and low-temperature reaction control device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

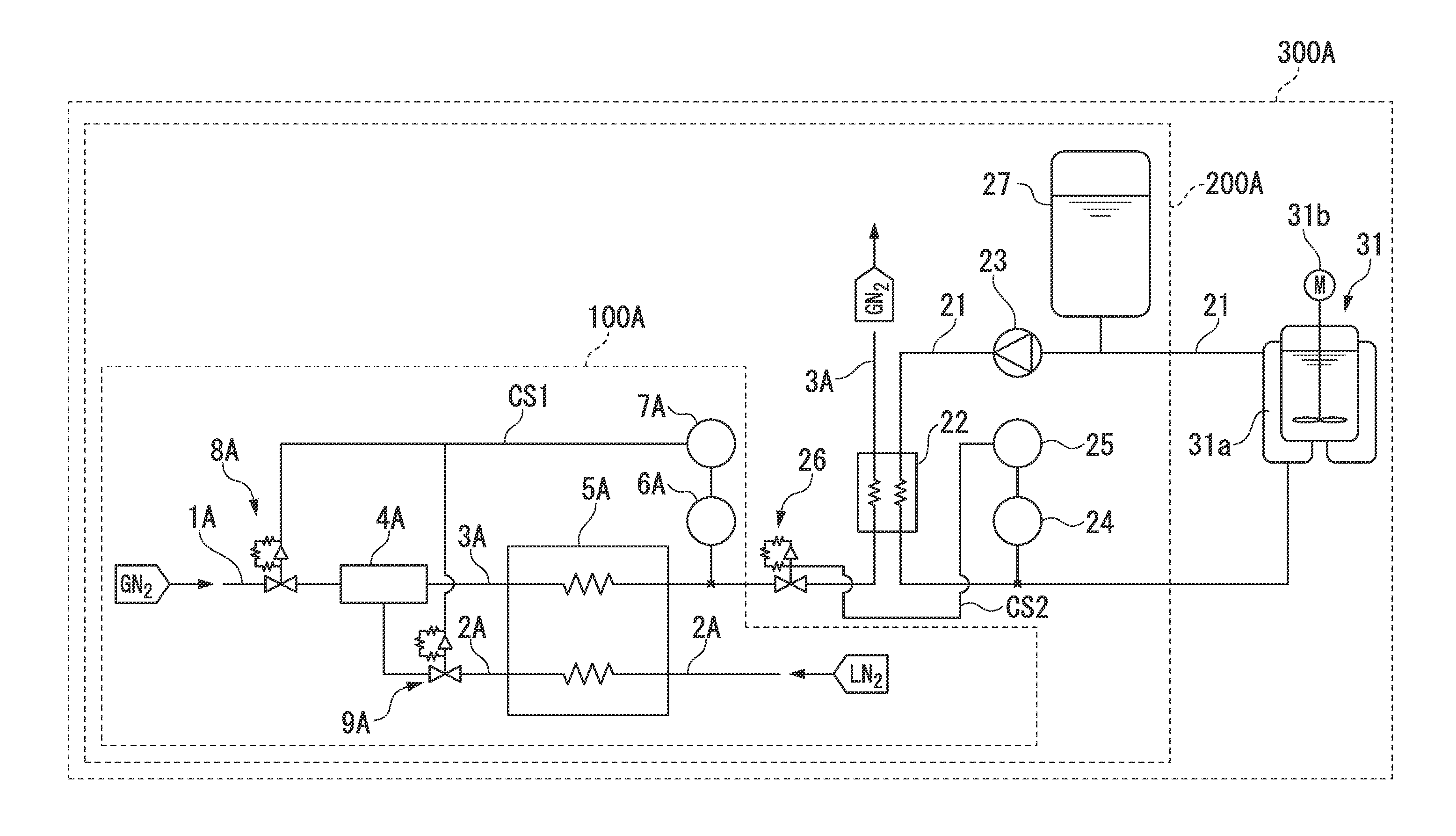

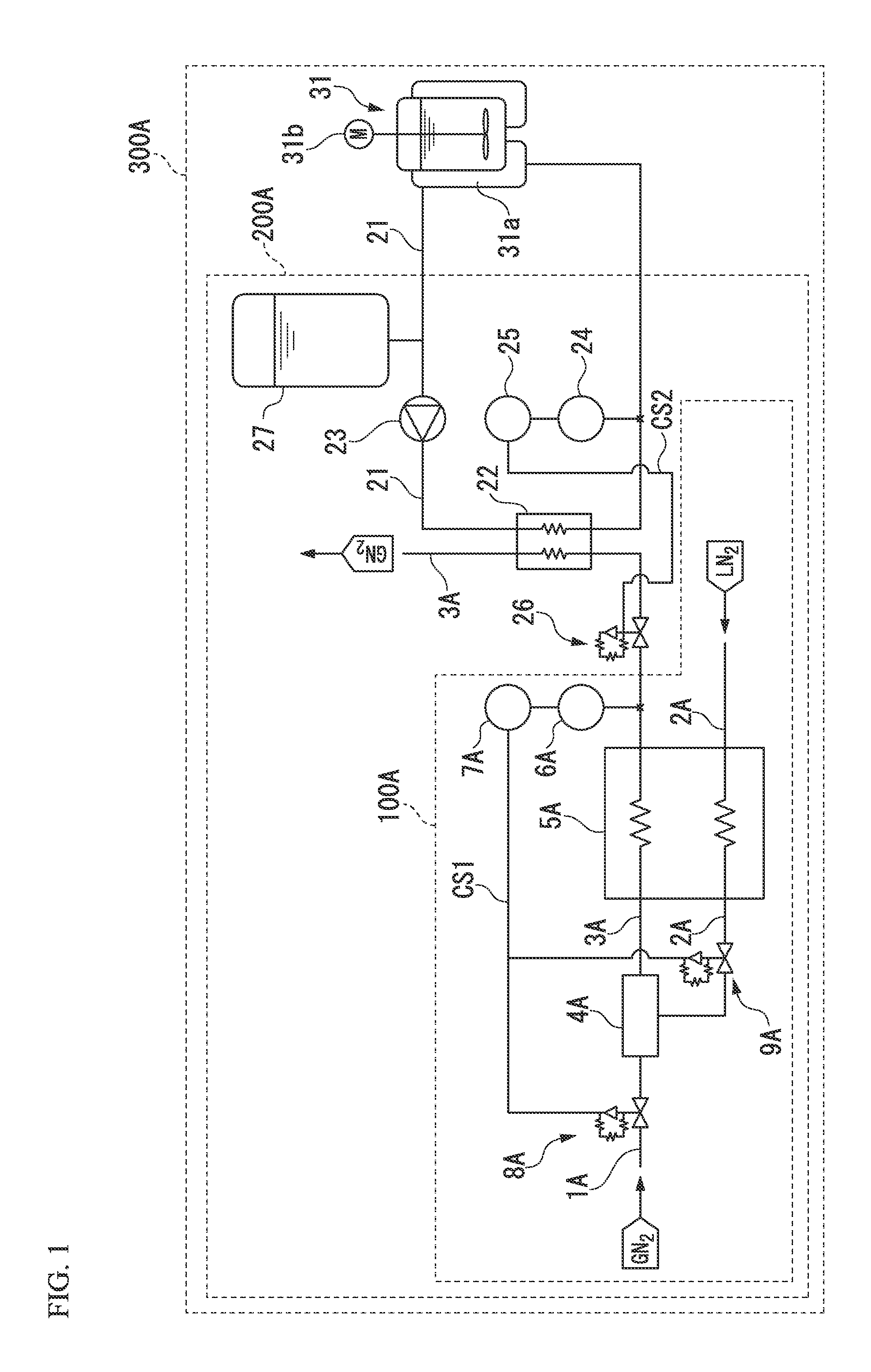

[0058]A low-temperature gas supply device 100A, heat transfer medium-cooling device 200A, and low-temperature reaction control device 300A according to the first embodiment of the present invention will be explained. FIG. 1 is a schematic diagram according to the first embodiment, in which a low-temperature gas supply device, a heat transfer medium-cooling device, and low-temperature reaction control of the present invention are used.

[0059]As shown in FIG. 1, a low-temperature gas supply device 100A according to the first embodiment of the present invention includes a room temperature route 1A, from an one end of which a room temperature nitrogen gas (GN2)NNG is introduced as a gas of higher temperature than a low-temperature-liquefied gas described below, a low-temperature route 2A, from an one end of which a liquefied nitrogen (LN2)LN (for example, −196° C.) is introduced as the low-temperature-liquefied gas, a mixing route 3A, in which a mixed gas and a low-temperature nitrogen g...

second embodiment

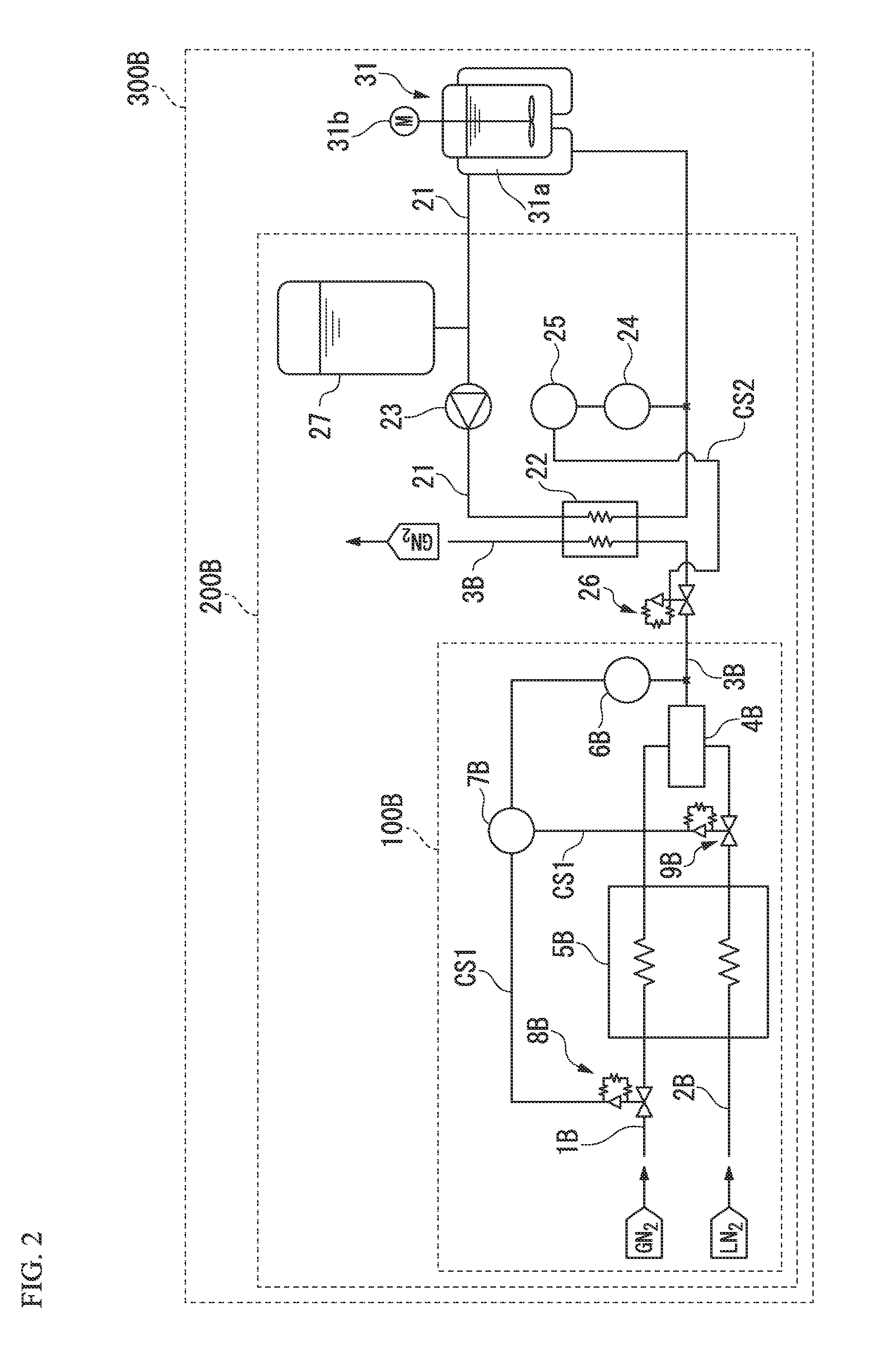

[0073]Next, the second embodiment according to the present invention will be explained. FIG. 2 shows a schematic diagram according to the second embodiment including the low-temperature gas supply device, the heat transfer medium-cooling device, the low-temperature reaction control device of the present invention.

[0074]As shown in FIG. 2, a low-temperature gas supply device 100B according to the second embodiment of the present invention includes a room temperature route 1B, from an one end of which a room temperature nitrogen gas (GN2)NNG is introduced, a low-temperature route 2B, from an one end of which a liquefied nitrogen (LN2)LN (for example, −196° C.) is introduced, a mixing route 3B, in which a low-temperature nitrogen gas refrigerant described below flows, a first heat exchanger 5B, in which the room temperature nitrogen gas NNG introduced from the room temperature route 113 and the liquefied nitrogen LN introduced from the low-temperature route 2B are heat-exchanged with e...

third embodiment

[0088]Next, the third embodiment according to the present invention will be explained. FIG. 3 shows a schematic diagram according to the third embodiment including the low-temperature gas supply device, the heat transfer medium-cooling device, and the low-temperature reaction control device of the present invention.

[0089]As shown in FIG. 3, a low-temperature gas supply device 100C according to the third embodiment of the present invention includes a room temperature route 1C, from an one end of which a room temperature nitrogen gas (GN2)NNG is introduced as a gas of higher temperature than a low-temperature-liquefied gas described below, a low-temperature route 2C, from one end of which a liquefied nitrogen (LN2)LN (for example, −196° C.) is introduced as the low-temperature-liquefied gas, a mixing route 3C, in which a mixed gas and a low-temperature nitrogen gas refrigerant described below flows, an ejector (mixed device) 4C, in which the room temperature nitrogen gas NNG introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com