Method of and Apparatus for Shot Peening Stainless Steel Tubing

a technology of stainless steel tubing and apparatus, which is applied in the direction of heat treatment apparatus, furnaces, furnaces, etc., can solve the problems of unplanned shutdown of power generation facilities, reduced cold working efficiency imparted to the tube surface, and loss of a portion of the kinetic energy of the sho

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

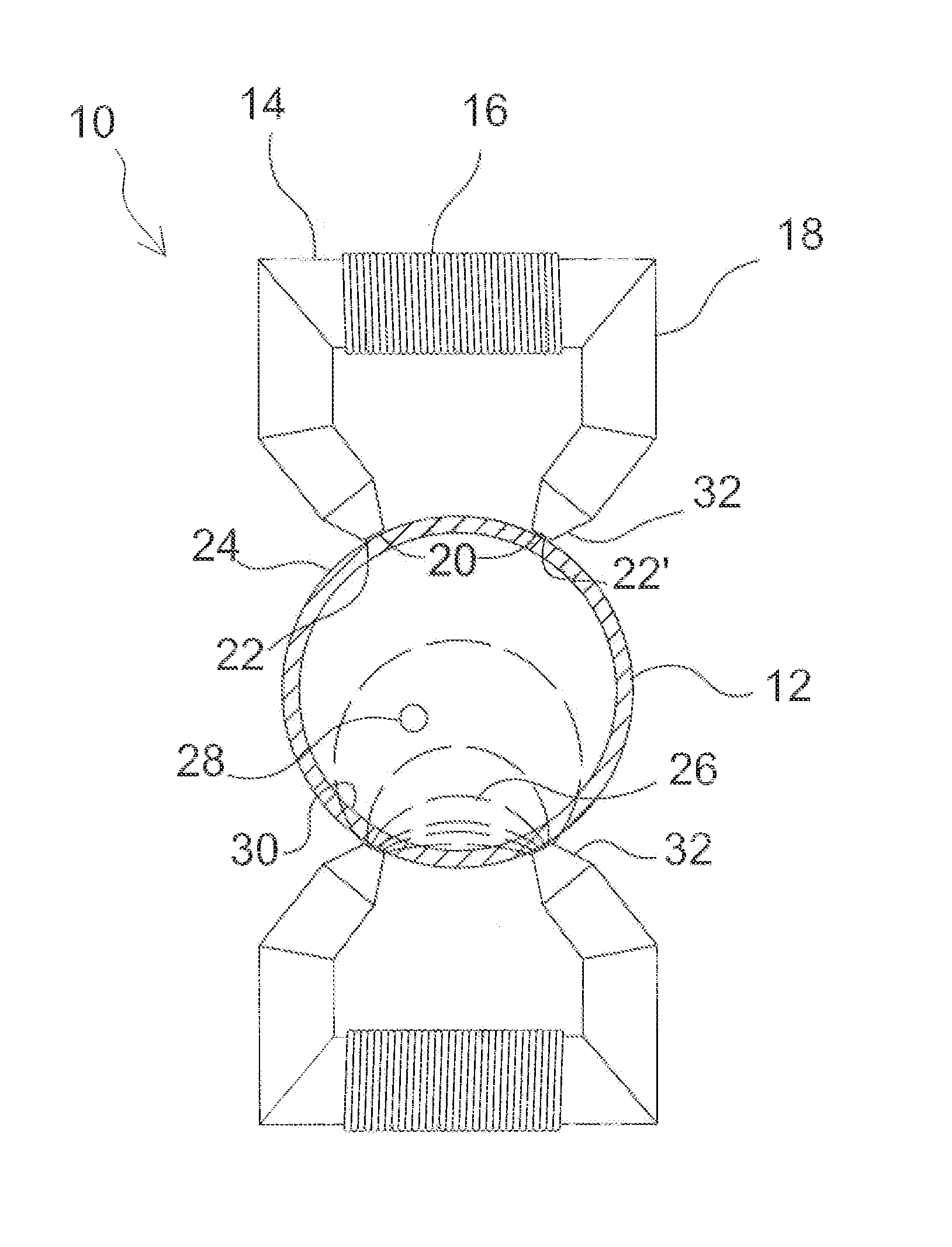

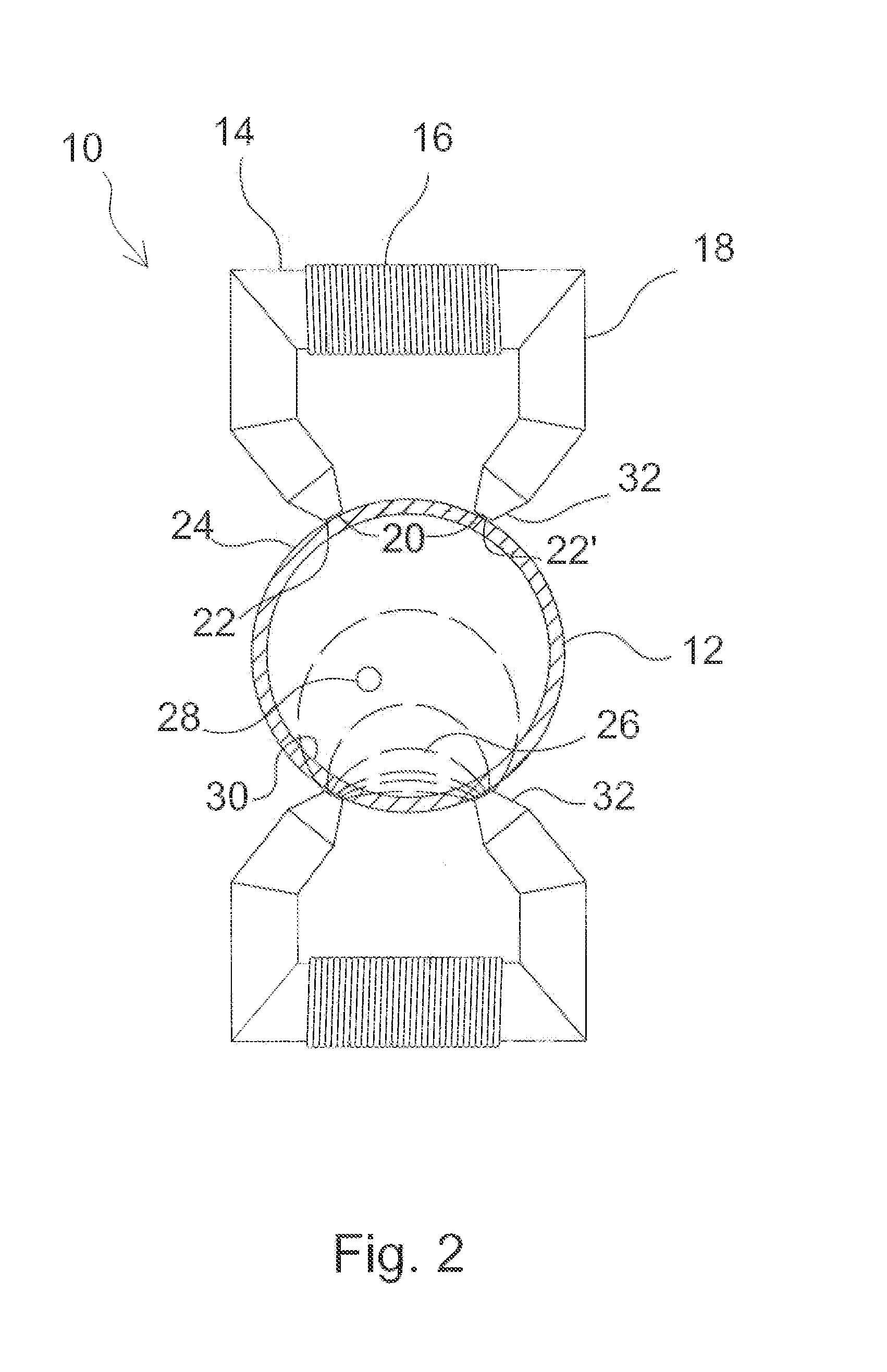

[0038]FIG. 5 schematically shows a cross-sectional view corresponding to FIGS. 2 and 4 of the present invention for shot peening a cross section of a stainless steel tube 12. (FIG. 5 also shows a cross section across the tube taken along line 4-4 of FIG. 3.) The shot peening apparatus 10″ of FIG. 5 differs from that of FIGS. 1 and 2 in comprising a rotating device 54, here, symbolically, represented by wheels 54, to rotate a frame 40 to which the electromagnets 14 are attached. The number of electromagnets 14 is, here, as an example, four. A controller (not shown in FIG. 5) rotates the frame 40 either continuously or, preferably, back and forth by about ninety degrees, i.e., the angle between adjacent electromagnets. In the apparatus of FIG. 5, the number of electromagnets can be relatively small, and yet, it is not necessary to rotate the tube 12 to evenly shot peen a cross section of the tube 12. This apparatus 10″ is especially useful in applications in which shot peening is perf...

fourth embodiment

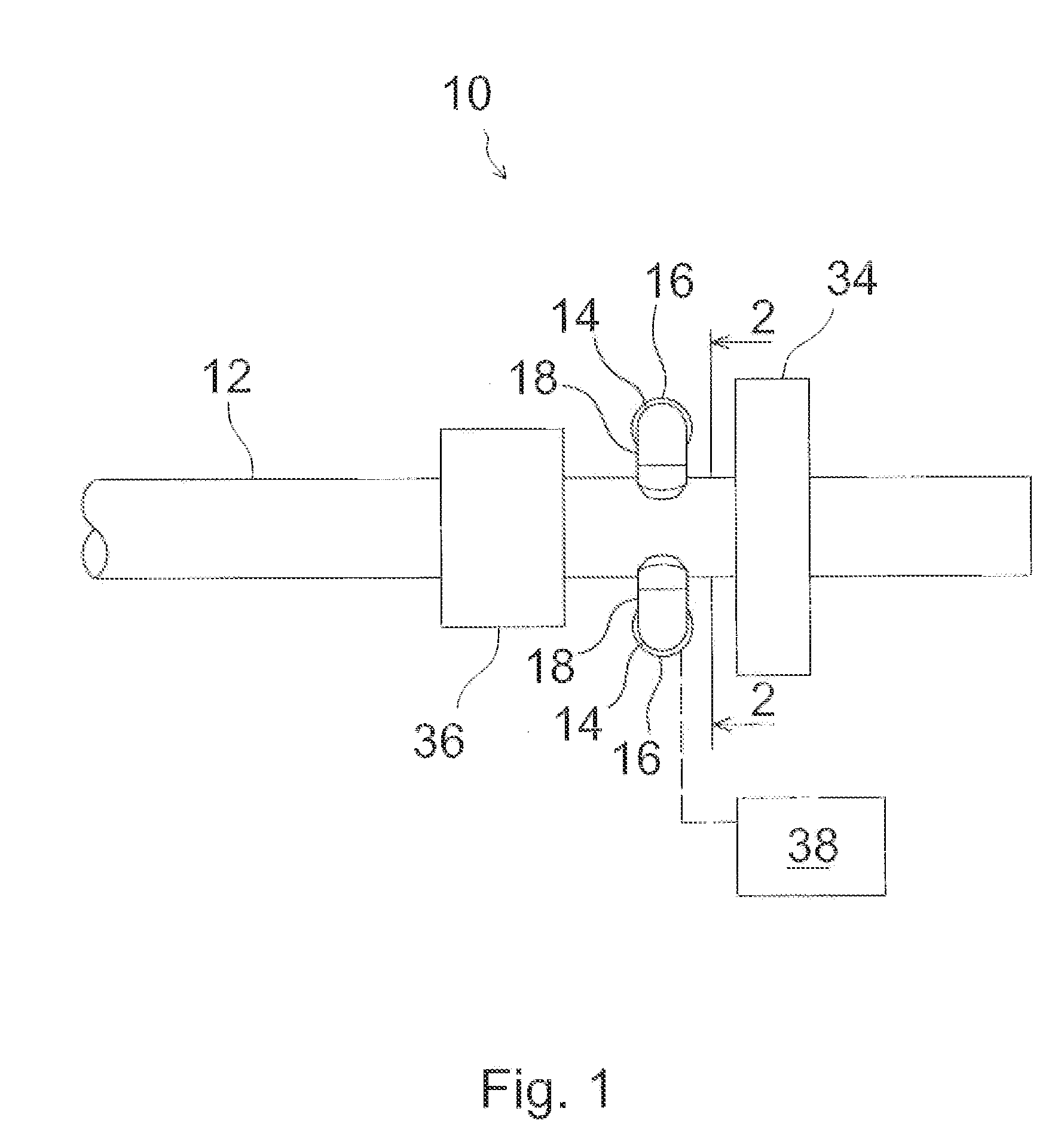

[0040]FIG. 6 schematically shows a side view of the present invention for shot peening a stainless steel tube 12. This embodiment differs from the previous ones in that the frame for the electromagnets 36′ comprises multiple rings 44.1, 44.2, and 44.3, to each of which is attached multiple electromagnets 36′ (not shown in FIG. 6). FIG. 6 shows three rings, each of which has, for example, four electromagnets 36′. The number of rings can alternatively be two, or it can be more than three, such as four. Also, the number of electromagnets 36′ in each ring can be, for example, from three to six, or even more. The idea of the embodiment of FIG. 6 is that, instead of arranging a very large number of electromagnets 36 on a single ring, such as eight electromagnets 36 in the embodiment of FIG. 4, the electromagnets 36′ are divided between multiple rings. Thereby, space is provided to more freely optimize the size and shape of the electromagnets 36′, and, thereby, an especially good magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com