Hot Surface Igniter With Fuel Assist

a technology of fuel assist and hot surface, which is applied in the direction of burner control devices, combustion regulation, burners, etc., can solve the problems of unburned fuel, reduced combustion efficiency, and undesirable combustion performance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

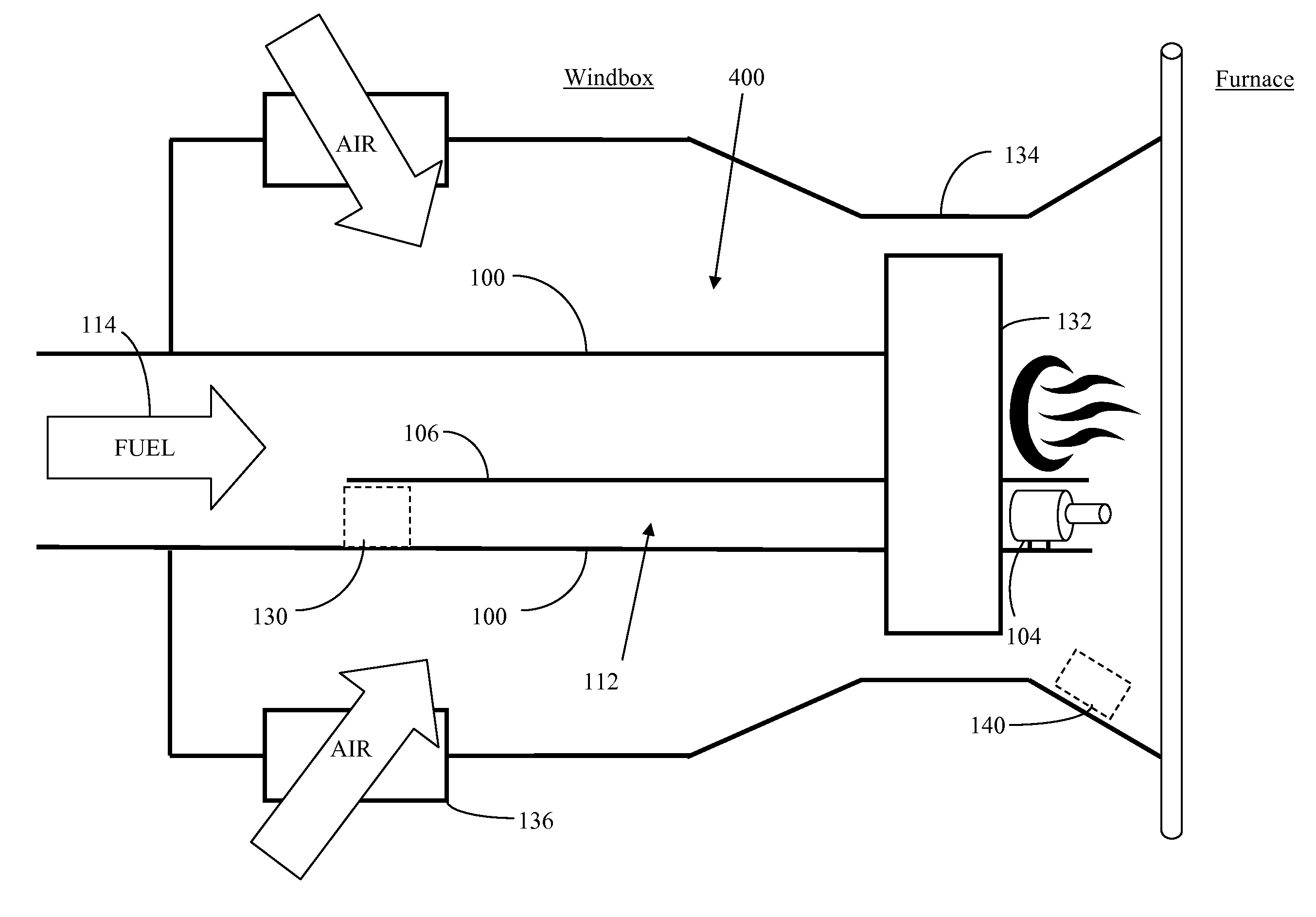

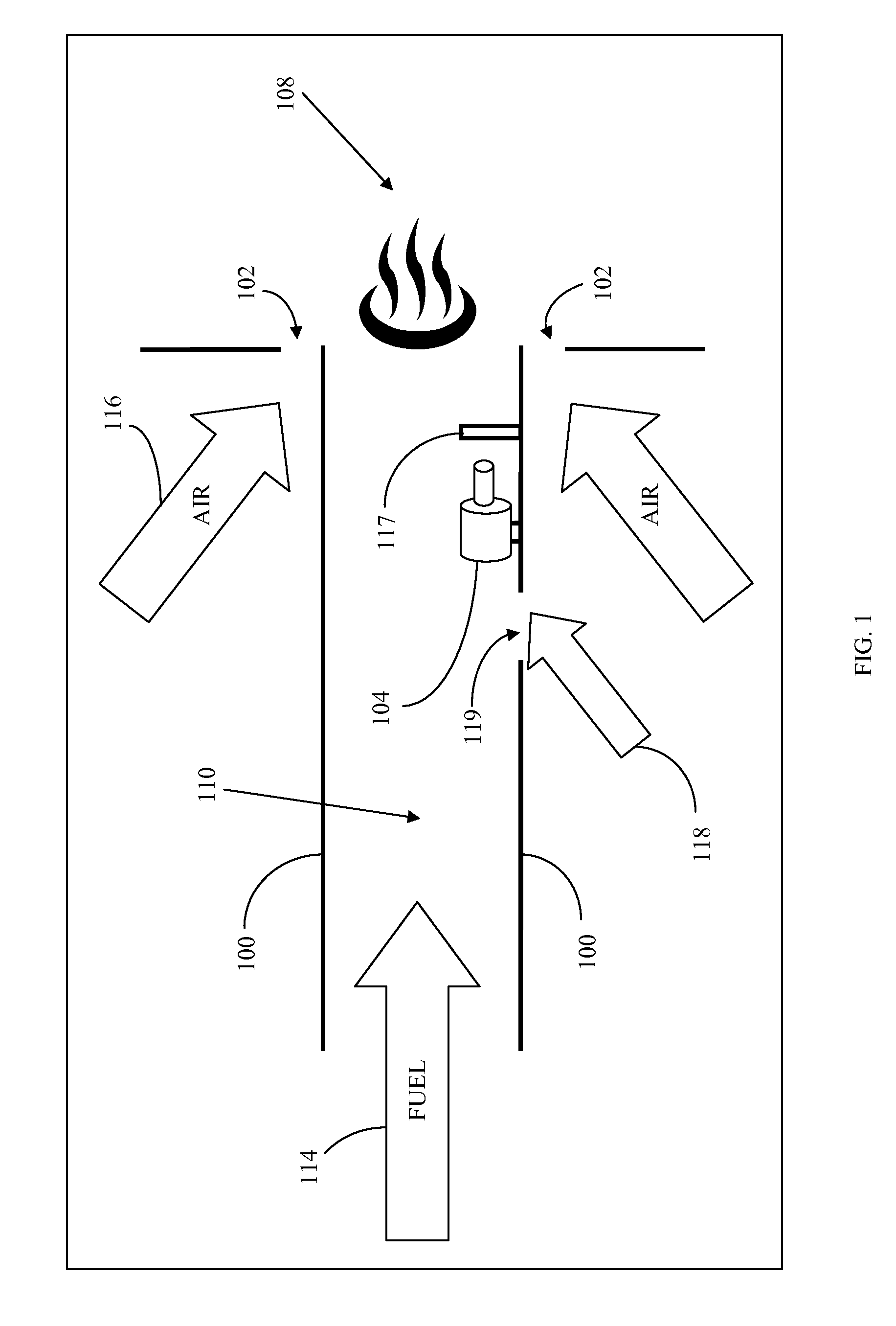

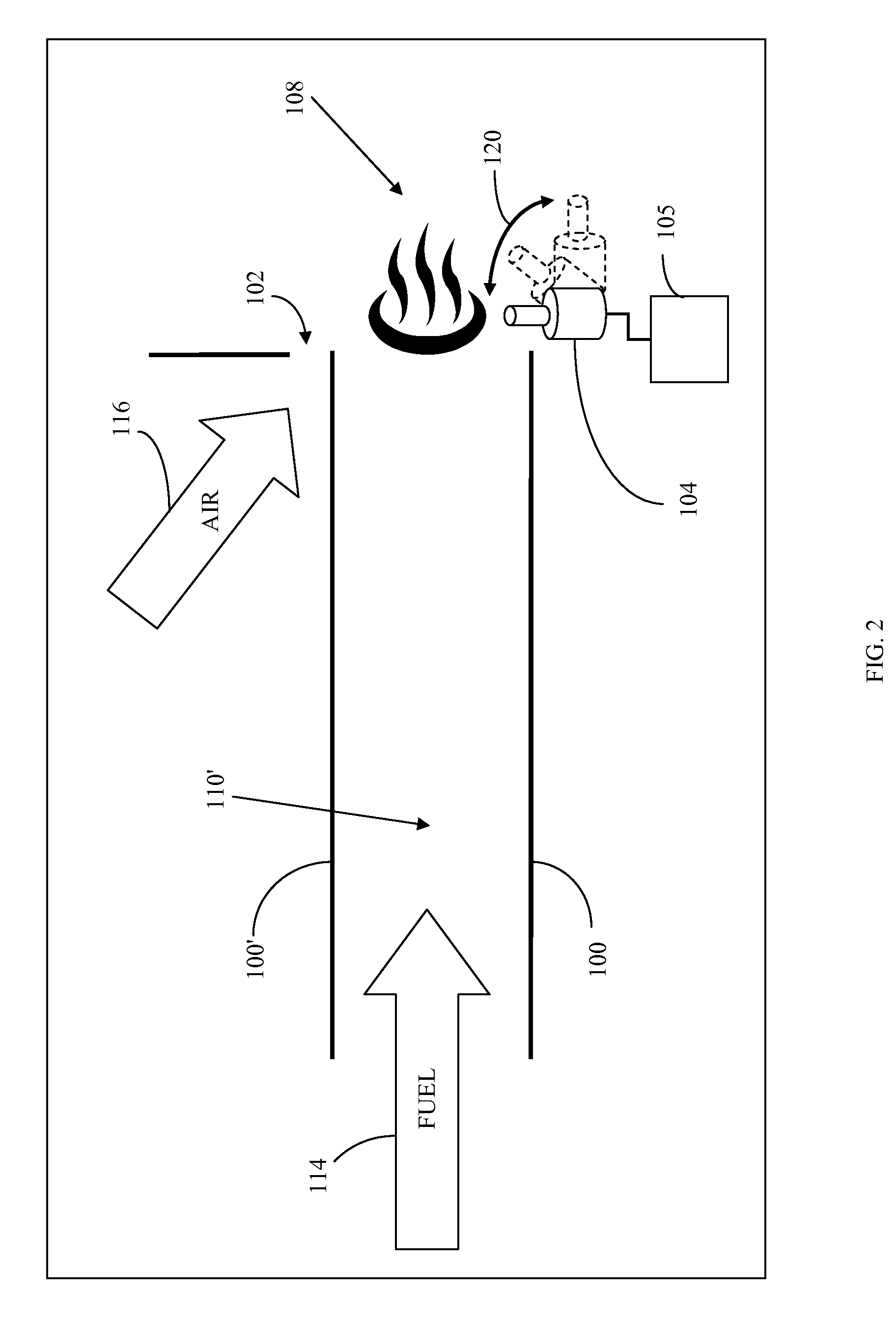

[0024]The present teachings are described more fully hereinafter with reference to the accompanying drawings, in which the present embodiments are shown. The following description is presented for illustrative purposes only and the present teachings should not be limited to these embodiments.

[0025]Large-scale combustion systems include utility power plants, paper& pulp mills, chemical plants, oil refineries, ethanol plants, marine vessels, and diesel engines, among others. Typically, utility & industrial boilers and transportation industries utilize steam generators ranging in size from 10 MW to 800 MW (50,000 to 5,500,000 lb / hr steam flow) and run on any number of different types of fuels, including coal, natural gas, fuel oil, refinery gas, and biofuel, although not limited thereto. Such systems require reliable ignition sources in order to maximize efficiency and to minimize risks associated with unintended explosions.

[0026]Typically, large-scale combustion systems utilize pilot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com