Conveying device and process for operating the same

a technology of conveyor system and inclination angle, which is applied in the direction of conveyor parts, loading/unloading, transportation and packaging, etc., can solve the problems of reducing the mobility and versatility of a tripper conveyor system, limiting the mobility and versatility of the system, and not being able to achieve the reduction of friction at higher inclination angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

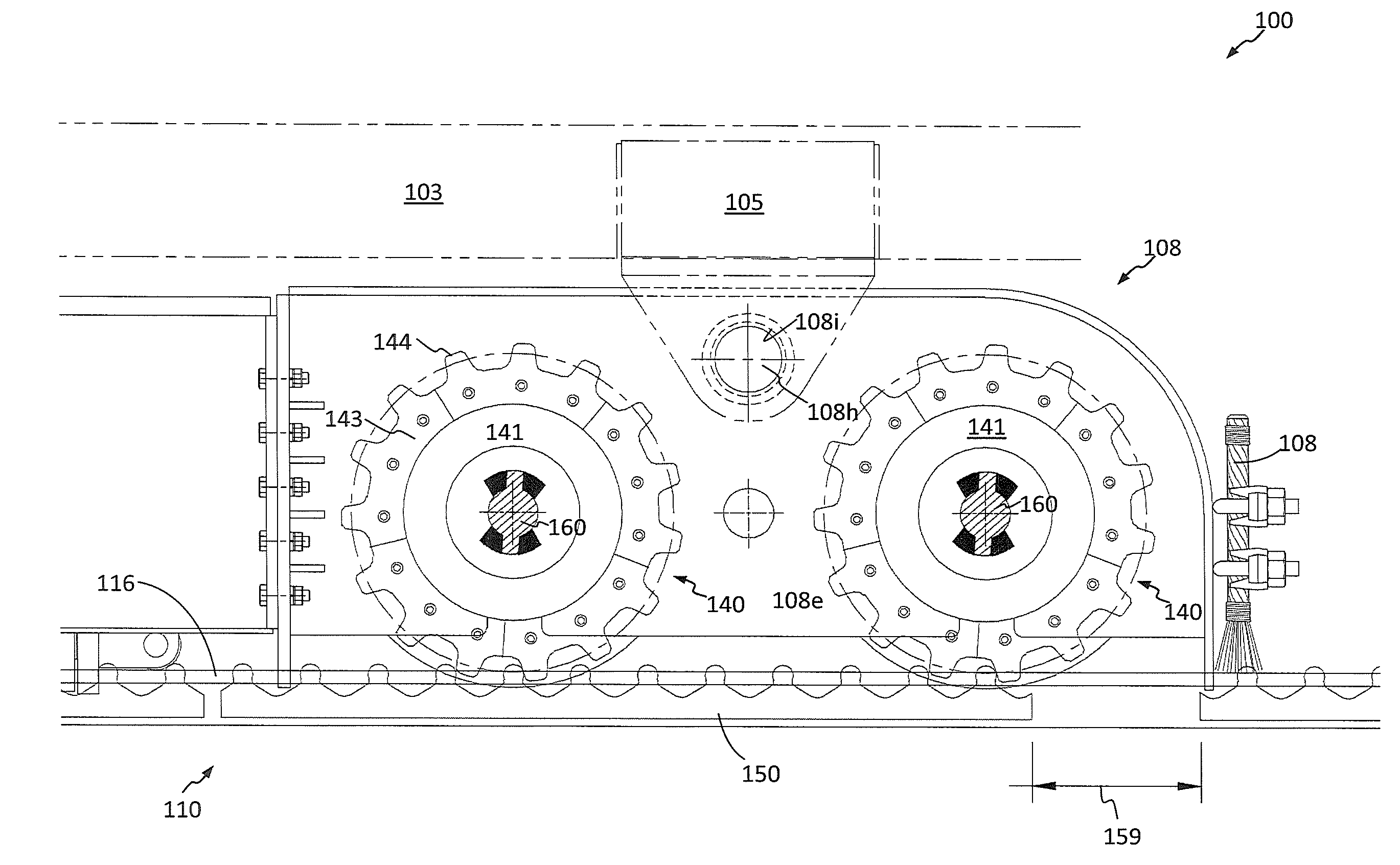

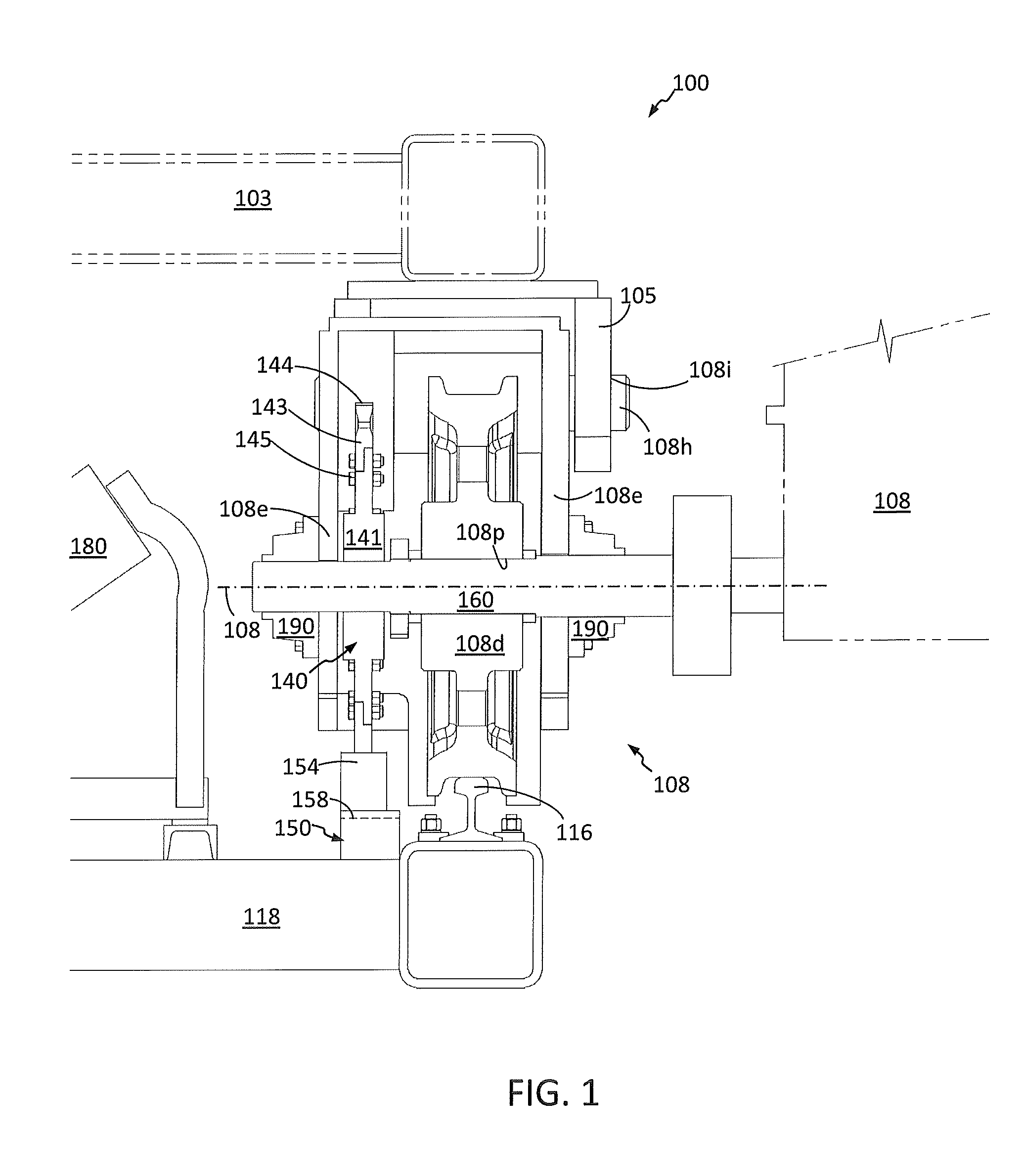

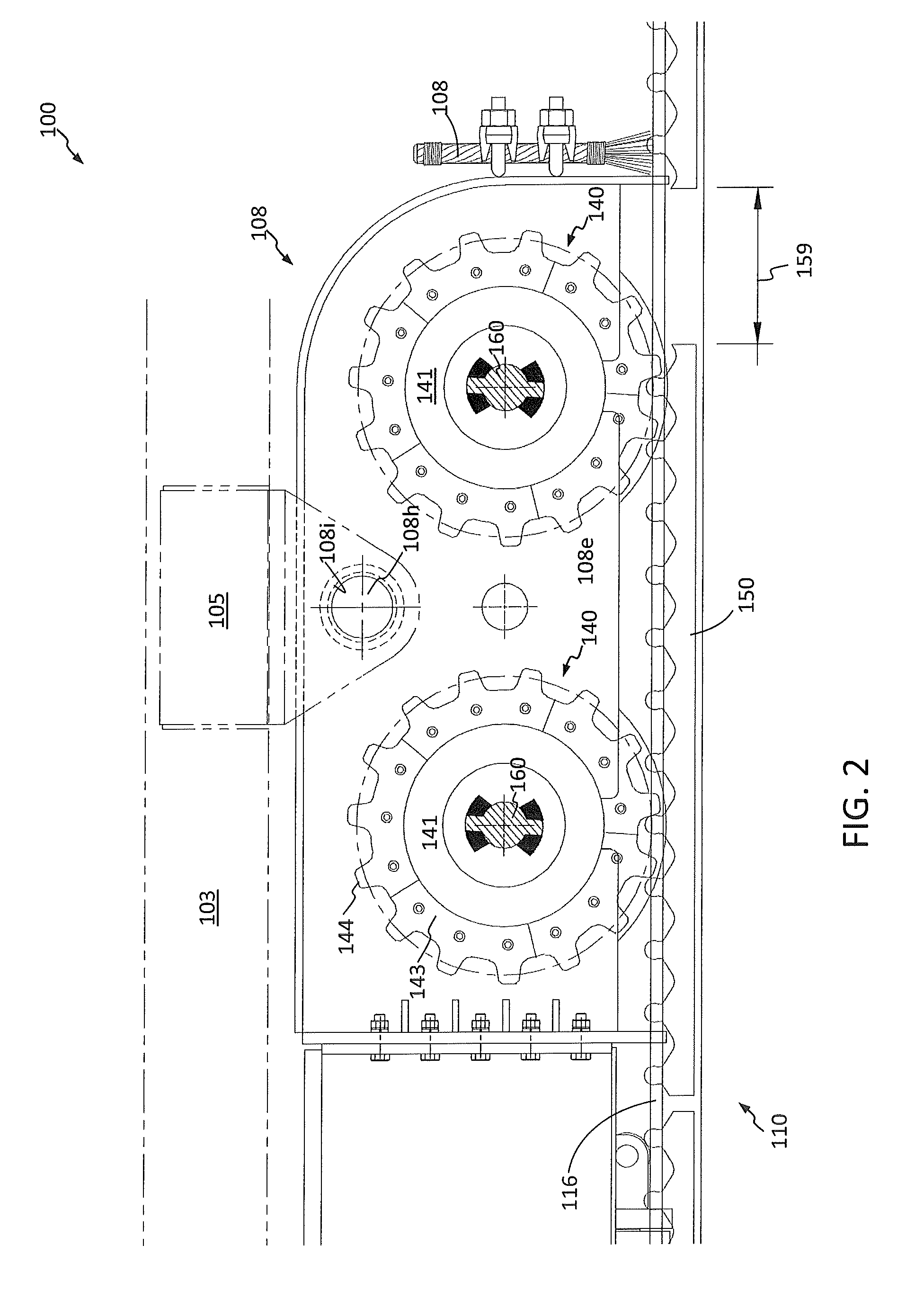

[0045]FIGS. 1-8 show a direct engagement drive system 108 for a tripper conveyor system according to some embodiments. A tripper 100 configured to rest on a conveyor 110 comprises a tripper frame 103 and feet 105, to which one or more drive systems 108 are attached. Multiple drive systems 108 may be provided to each foot 105. For example, as shown, each foot 105 may comprise two drive systems 108. Depending on which direction the tripper 100 is traveling, one of the two drive systems 108 serves as a lead drive system and the other of the two drive systems 108 serves as a follow drive system. The drive systems 108 are secured to a mount 108e which may be pivotally attached to each foot 105 by way of a joint 108h and / or a bushing 108i. The mount 108e may completely encase portions of each drive system 108 to protect components of the drive system 108 from dust and dirt ingress. For example, in some embodiments, such as the one shown, mount 108e may comprise a wheel box constructed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com