Power module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

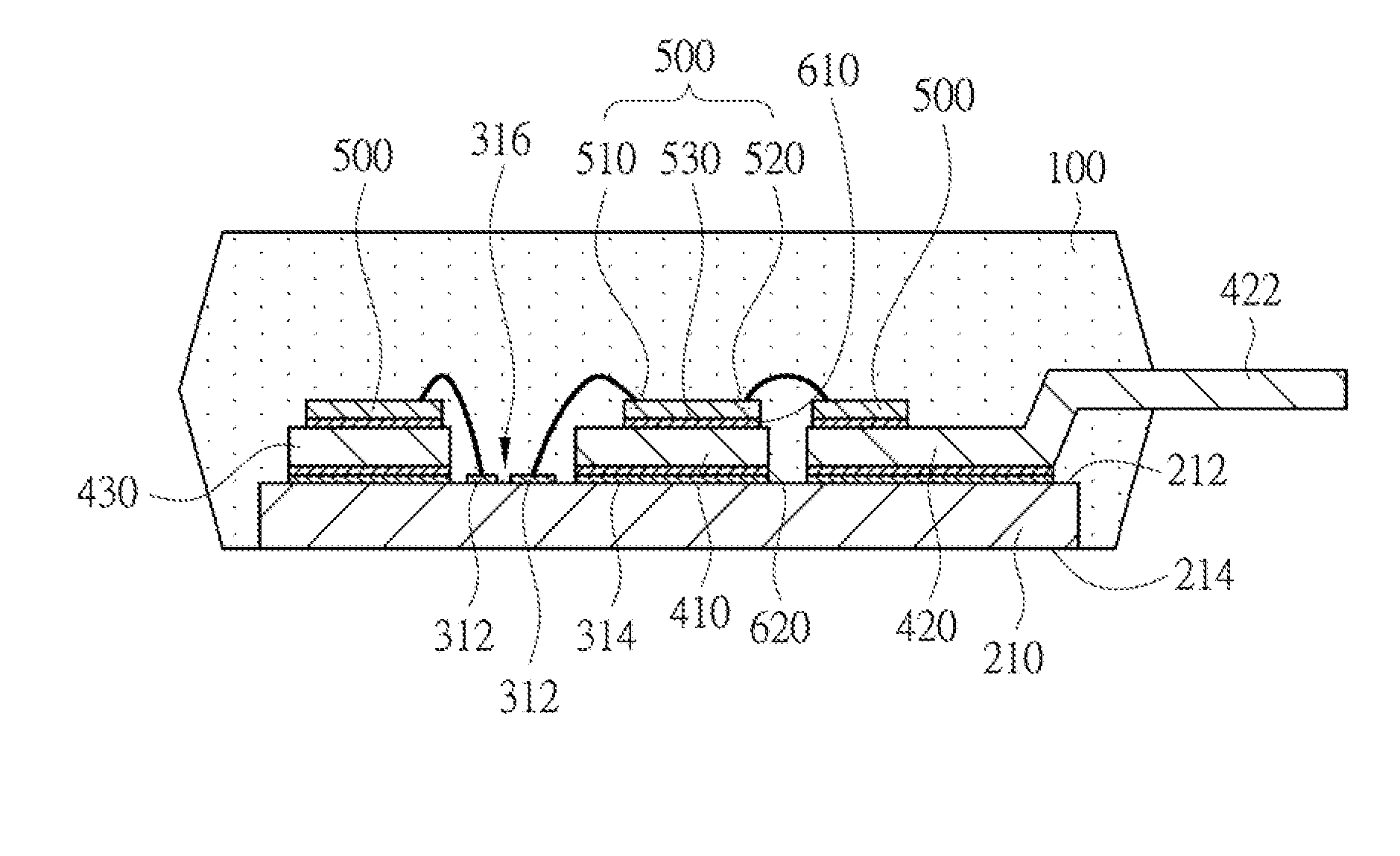

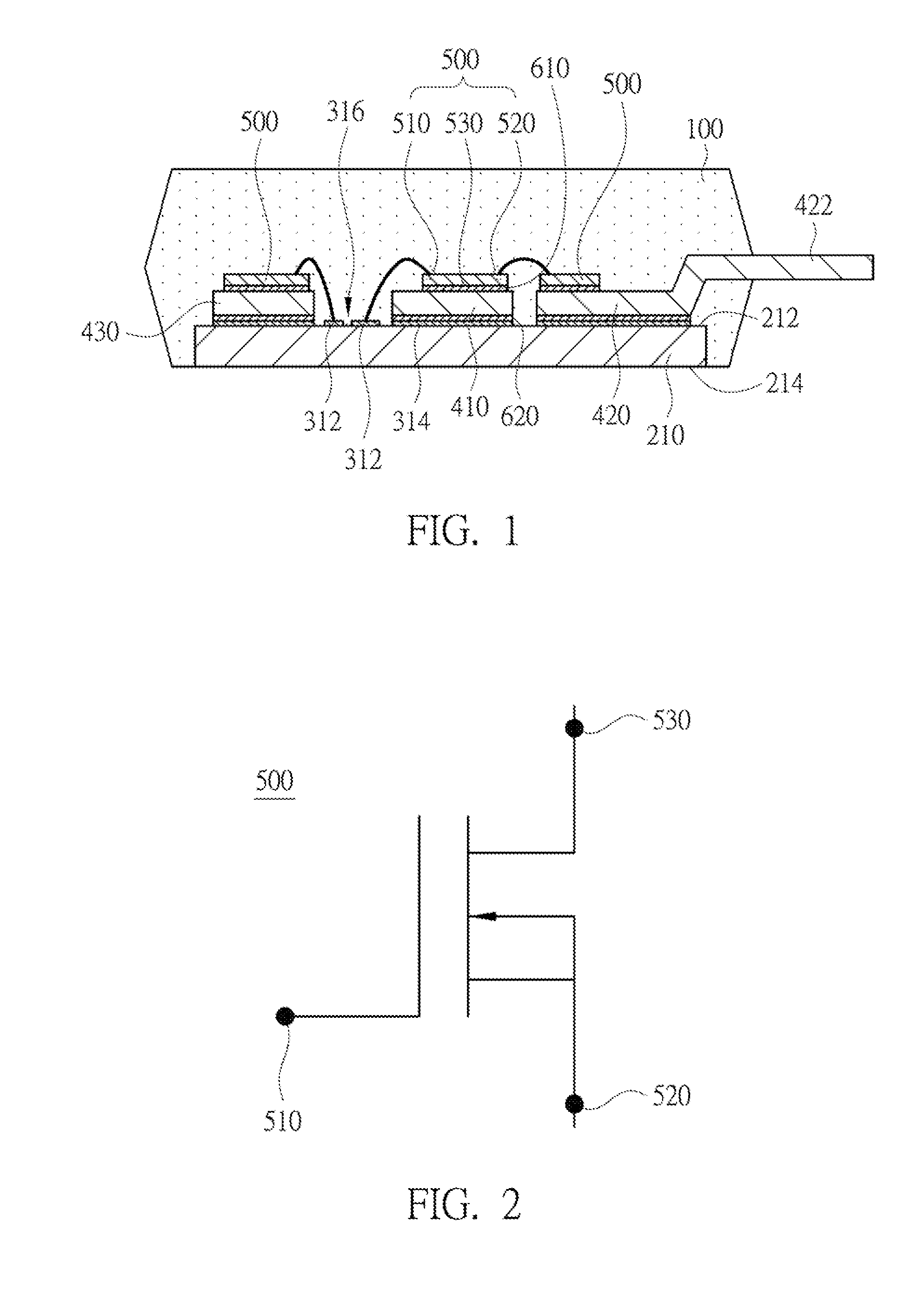

[0032]FIG. 1 is a diagram illustrating a cross-sectional view of a power module according to a first embodiment of the present invention. As shown in FIG. 1, the power module comprises a sealing body 100 and a first substrate 210. A first metal layer 210, a second metal layer 314, conductive structures 410, 420 and 430, and at least one power device 500 are disposed on the first substrate 210. The first substrate 210 is disposed in the sealing body 100. The sealing body 100 covers at least the first metal layer 312, the conductive structures 410 and 430, a part of the conductive structure 420 and the power device 500 for protection. The conductive structure 420 has an exposed part 422. The exposed part 422 is exposed out of the sealing body 100, and electrically connects to an external device. The exposed part 422 can be realized by a lead frame, for instance. The first substrate 210 comprises a top side 212 and a bottom side 214 which are relative to each other. The first metal lay...

second embodiment

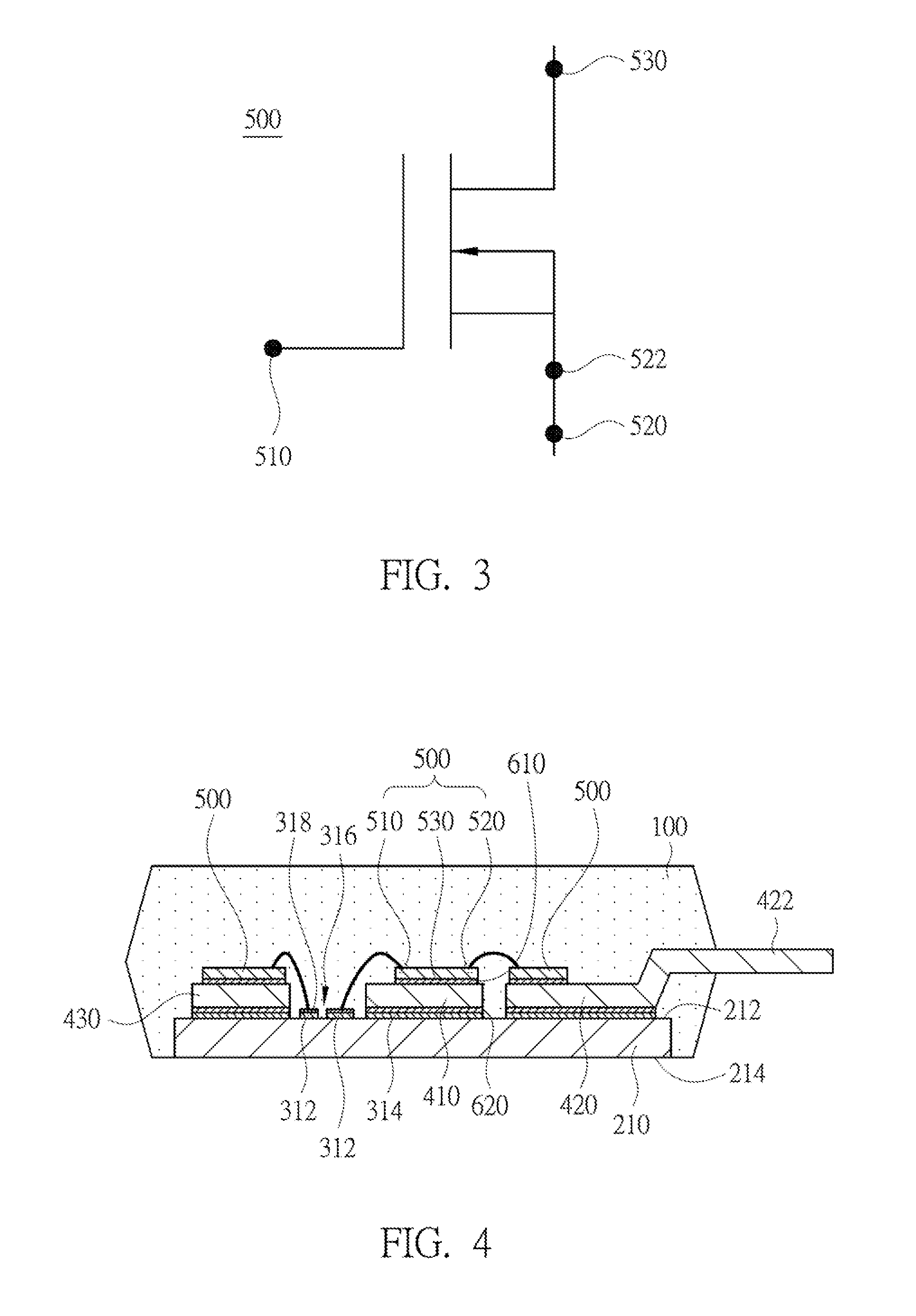

[0040]FIG. 4 is a diagram illustrating a cross-sectional view of a power module according to a second embodiment of the present invention. The present embodiment differs to the first embodiment mainly in that the power module of the present embodiment further comprises a plurality of flattening structures 318. The flattening structure 318 is disposed on a surface, which is opposite to the first substrate 210, of the first metal layer 312. The flattening structure 318 has a flat upper surface, which is suitable for wirings. For instance, the flattening structure 318 can be realized by a coating of platted nickel, silver, nickel gold or platted palladium, etc., on the first metal layer 312. Other technical features of the present embodiment are similar to those of the first embodiment, so relative descriptions are omitted hereinafter.

third embodiment

[0041]FIG. 5 is diagram illustrating a cross-sectional view of a power module according to a third embodiment of the present invention. The present embodiment differs to the first embodiment mainly in that the power module of the present embodiment further comprises an adhesive structure 710. The adhesive structure 710 is disposed between the conductive structure 410 and the first substrate 210, so as to conduct the heat of the conductive structure 410 to the first substrate 210. By also referring to FIG. 1 and FIG. 3 together, it can be observed that the adhesive structure 710 has replaced the second metal layer 314 and the bonding layer 620 under the conductive structure 410. Since the second metal layer 314 is omitted in the present embodiment, the manufacturing cost of the second metal layer 314 can be further saved. In the present embodiment, the adhesive structure 710 can be disposed below the conductive structure 410 so as to fill the gap between the conductive structures 410...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com