Fluid Machinery

a technology of fluid machinery and piston pumps, which is applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of reducing the lubrication state of each sliding section in the crank chamber, and achieves the effect of reducing the risk of a decrease in the volumetric efficiency of the piston pump, reducing the risk of a decrease in lubrication performance, and gasifying easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

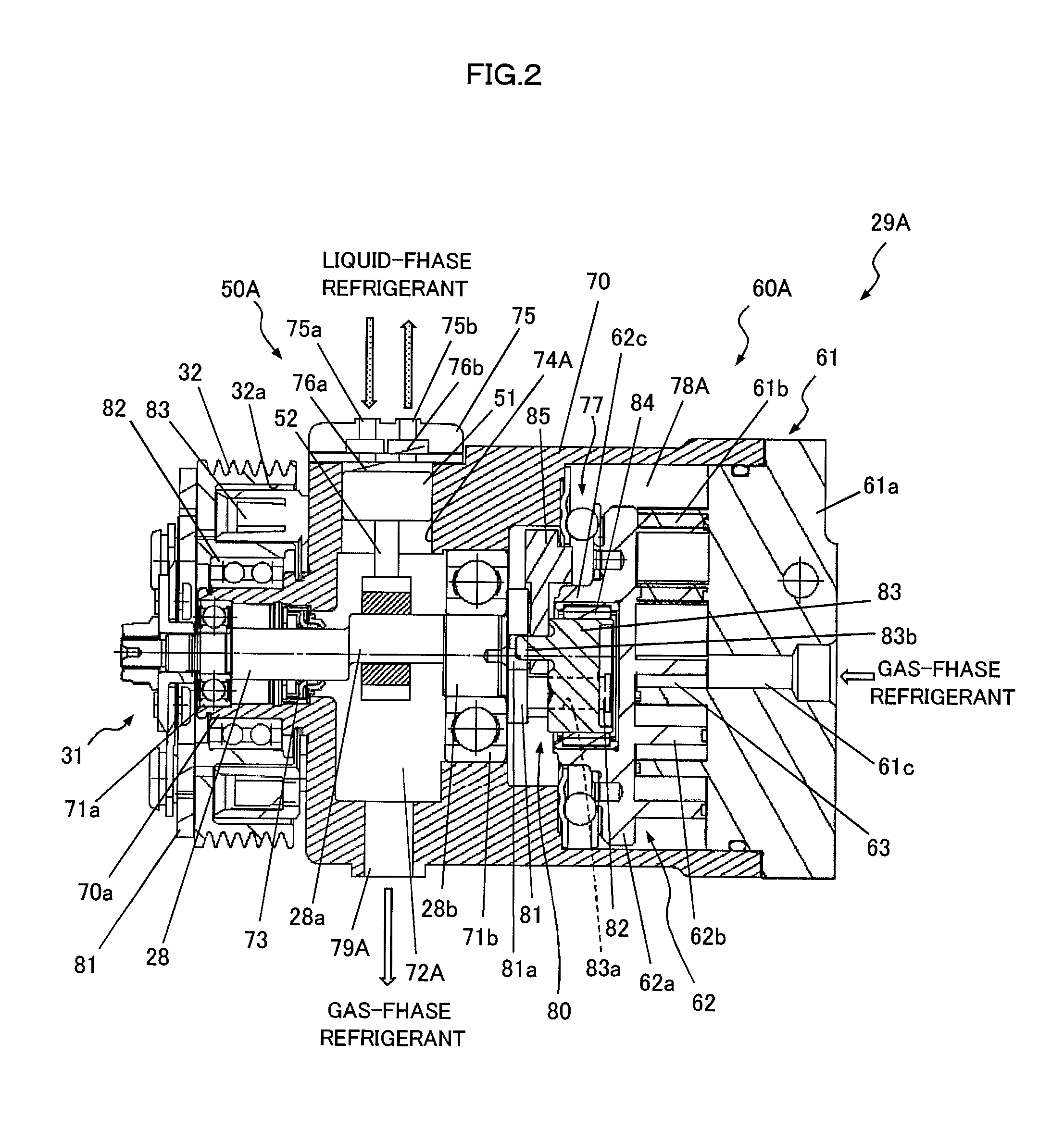

[0018]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

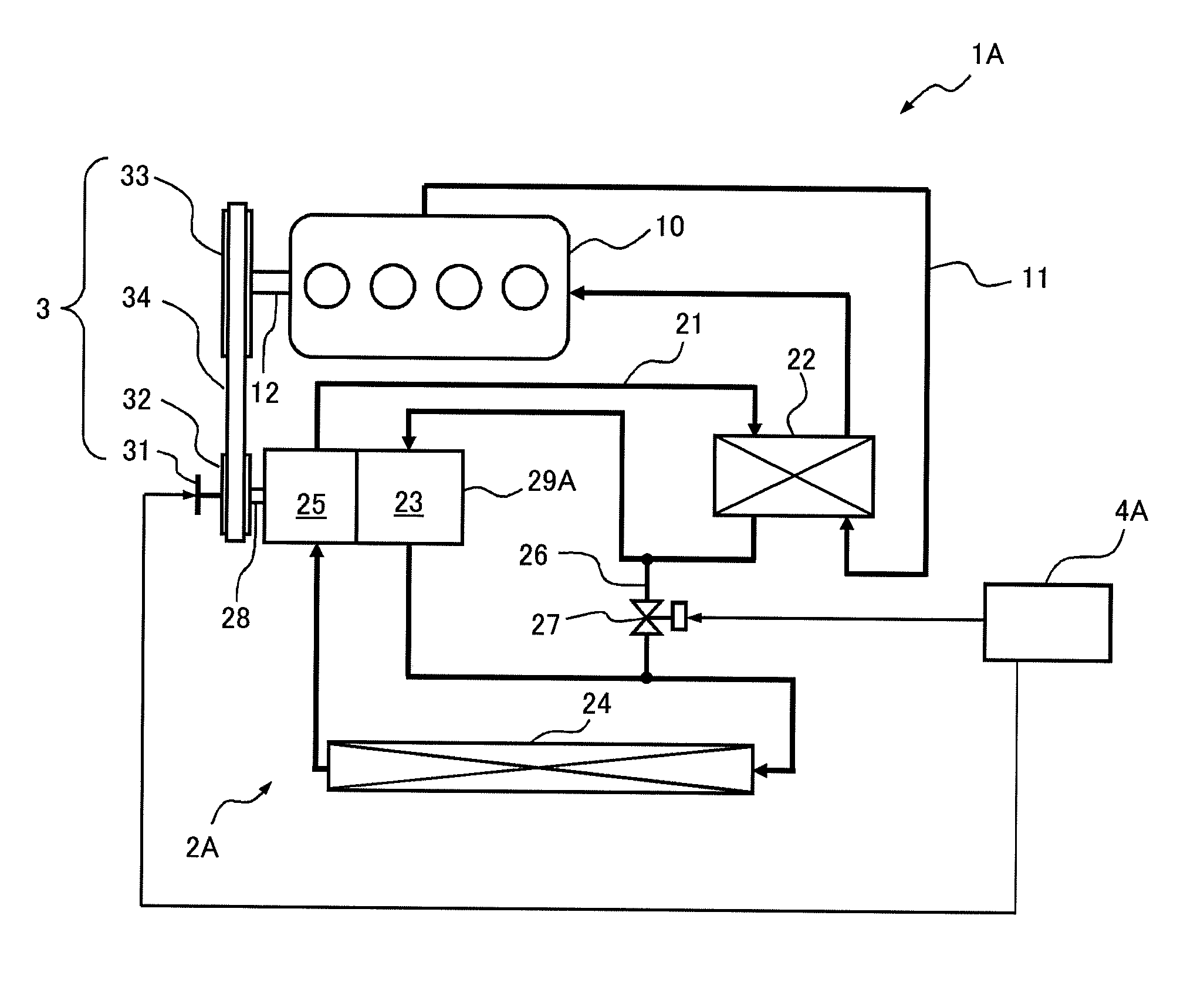

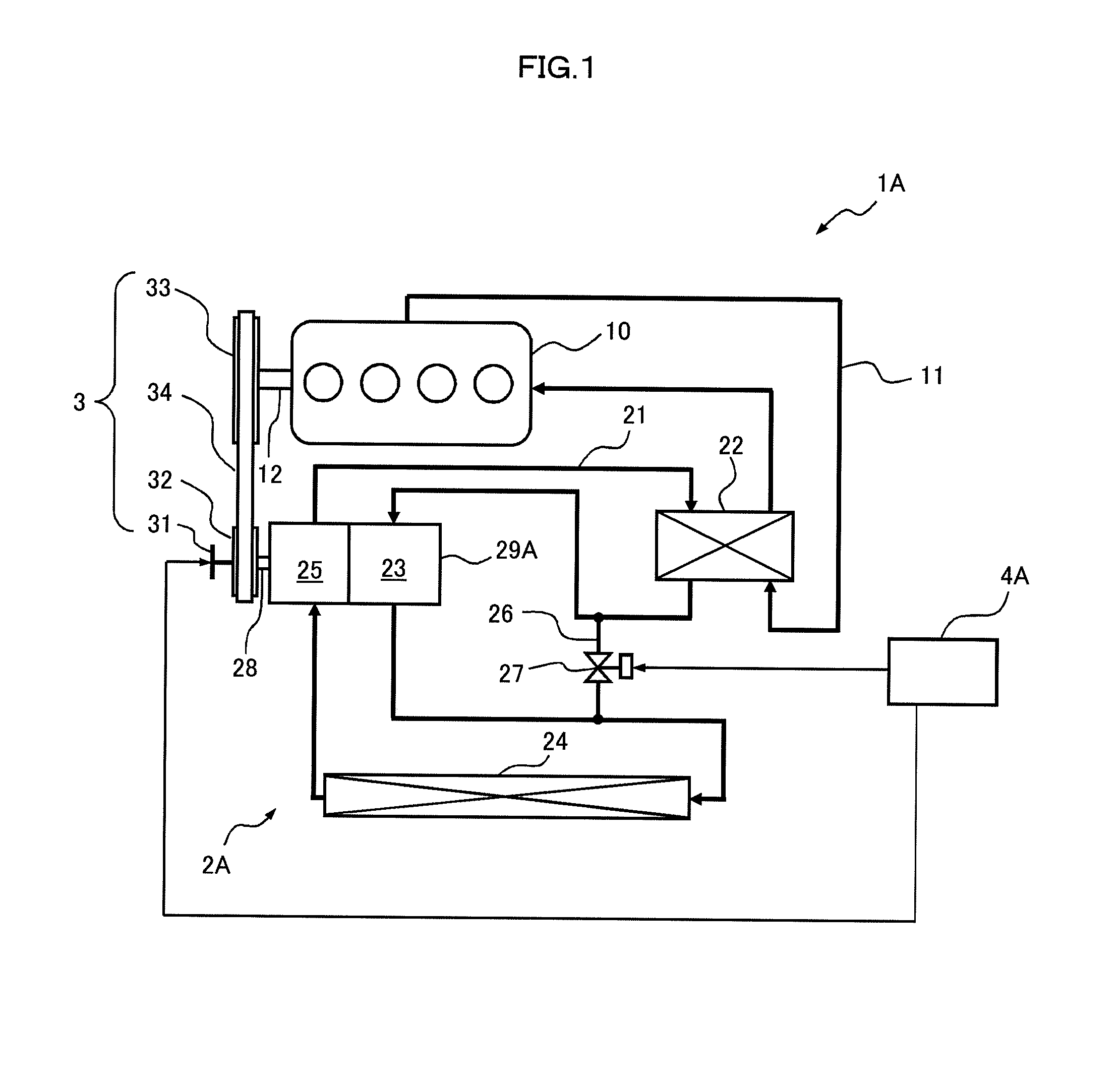

[0019]FIG. 1 illustrates a schematic configuration of an exhaust heat recovery apparatus 1A to which a fluid machinery according to the present invention is applied in a first embodiment. The exhaust heat recovery apparatus 1A is mounted on a vehicle and recovers and uses exhaust heat of an engine 10 of the vehicle.

[0020]The exhaust heat recovery apparatus 1A has a Rankine cycle 2A that recovers the exhaust heat of the engine 10 and converts it into power, a transmission mechanism 3 that performs the transmission of power between the Rankine cycle 2A and the engine 10, and a control unit 4A that controls the overall operation of the exhaust heat recovery apparatus 1.

[0021]The engine 10 is a water-cooled internal combustion engine and is cooled by an engine cooling water that circulates in a cooling water flow passage 11. A heater 22 of the Rankine cycle 2A to be desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com