Antistatic structure of array substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]To further expound the technical solution adopted in the present invention and the advantages thereof, a detailed description is given to a preferred embodiment of the present invention and the attached drawings.

[0042]The present invention will be explained with reference to a VA (Vertical Alignment) display mode, but is not limited to the VA display mode.

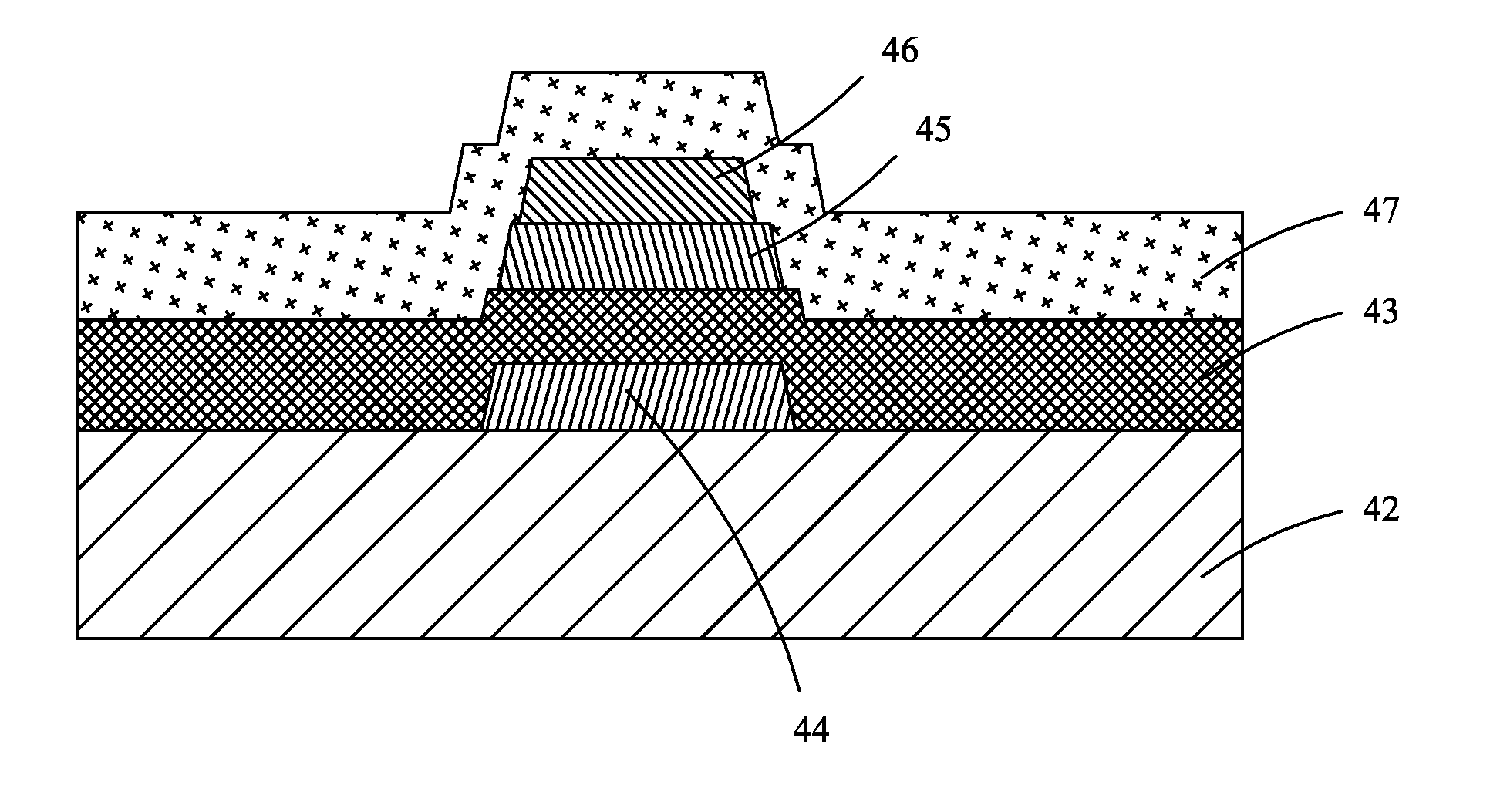

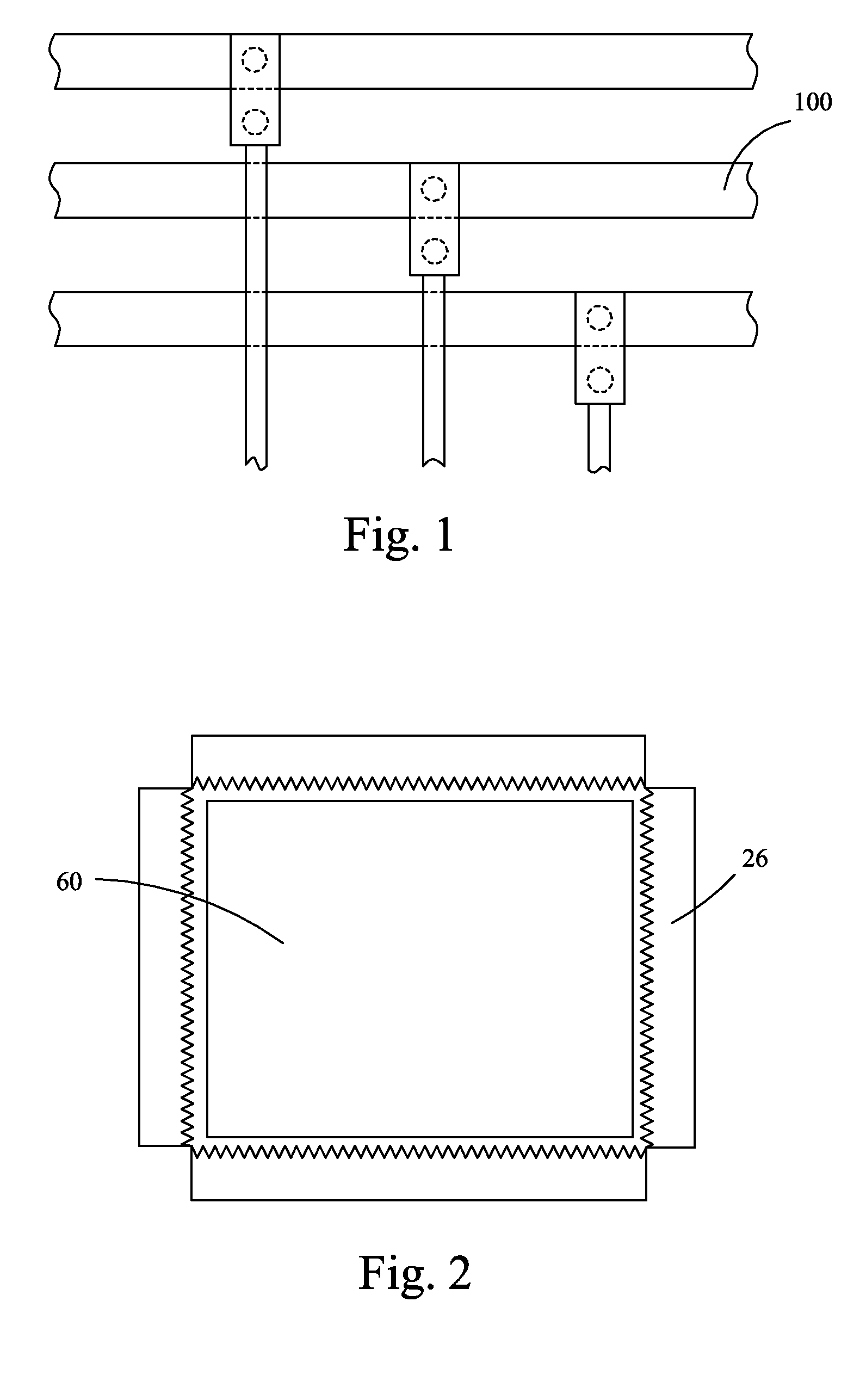

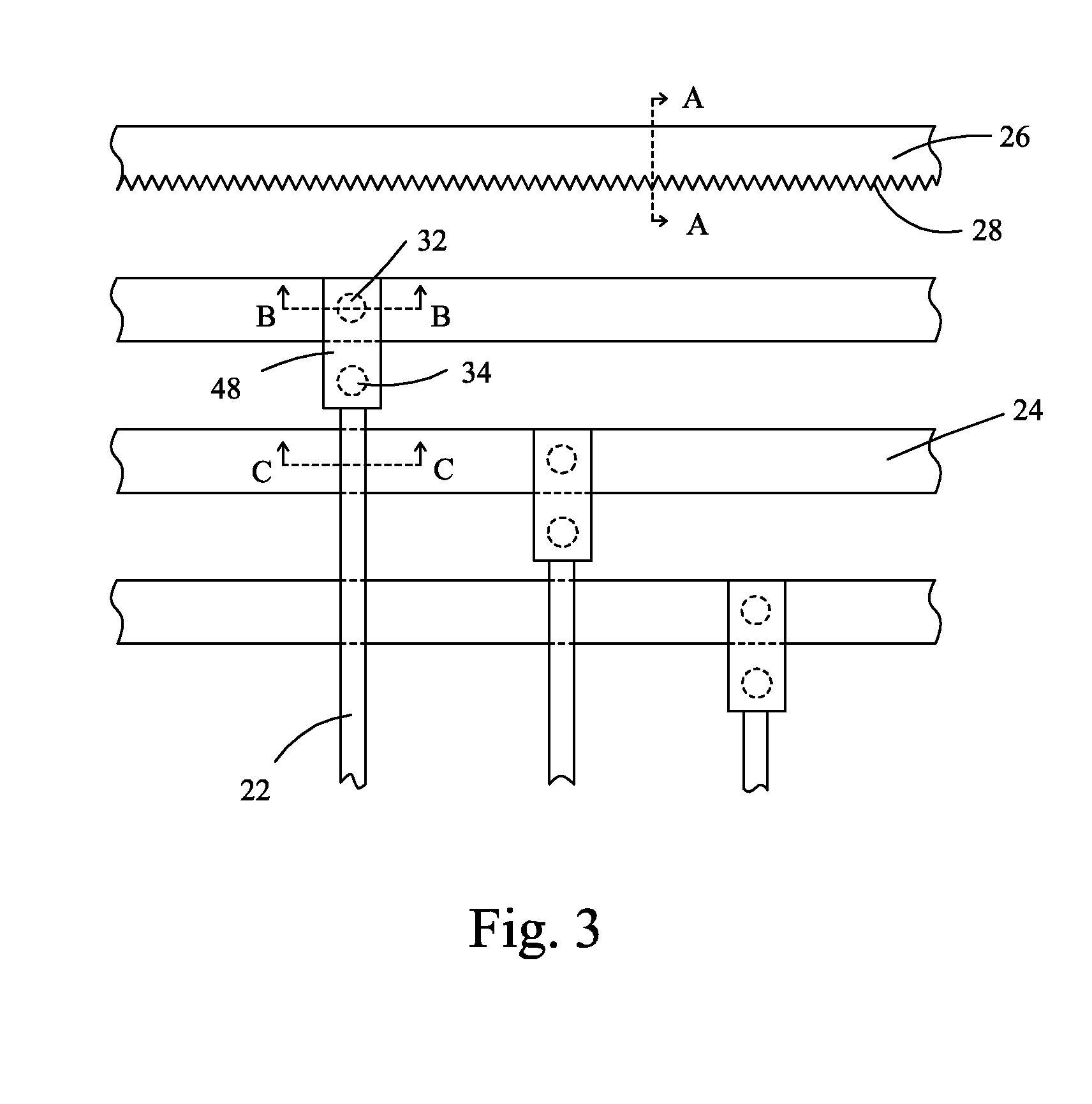

[0043]The present invention provides an arrangement that, in the manufacture of an array substrate, patternizes and forms dummy wires that are parallel to shorting bars at location adjacent to the shorting bars. In other words, the present invention provides an antistatic structure of an array substrate and, as shown in FIGS. 2 and 3, specifically comprises: an effective zone 60 of the array substrate and a plurality of dummy wires 26 surrounding the effective zone 60. The effective zone 60 of the array substrate comprises a plurality of signal wires 22 and a plurality of shorting bars 24 respectively in electrical connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com