Coating composition containing polyamide-imide resin

a technology of polyamideimide resin and coating composition, which is applied in the direction of coatings, lubricant compositions, additives, etc., can solve the problems of reproductive toxicity of amide-based solvents and diminish the lubrication durability of products treated therewith, and achieve excellent lubrication durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

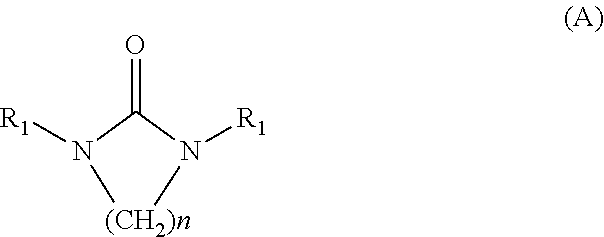

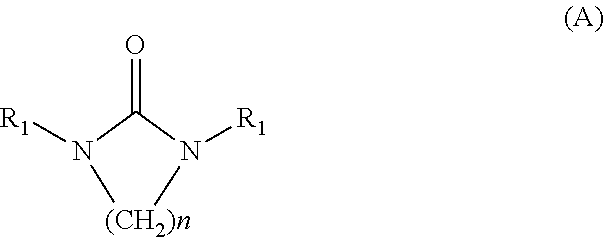

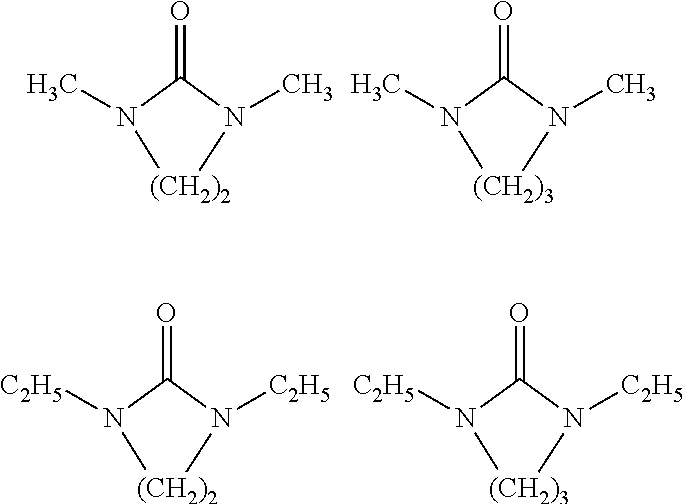

Method used

Image

Examples

example 1

Practical Example 1

[0045]Powdered graphite was added to a polyamide-imide resin solution (produced by Hitachi Chemical Co., Ltd., solid content: approximately 30% by mass) containing a polyamide-imide resin dissolved in 1,3-dimethyl-2-imidazolidinone (DMI) prepared in DMI, so that the content of the powdered graphite was 50 parts by mass per 100 parts by mass of the polyamide-imide resin, and mixed at room temperature. This mixture was diluted using DMI so that the solid content concentration was 15% by mass to form a coating composition to be used in evaluation tests.

reference example 1

[0048]A polyamide-imide resin solution (produced by Hitachi Chemical Co., Ltd., HPC-5000) in which a polyamide-imide resin was dissolved in N-methylpyrrolidone (NMP) was used, and powdered graphite was added, so that the content of the powdered graphite was 50 parts by mass per 100 parts by mass of the polyamide-imide resin, and mixed at room temperature. This mixture was diluted using NMP so that the solid content concentration was 15% by mass to form a coating composition to be used in evaluation tests.

Coating Method

[0049]The resulting coating composition was spray-coated onto a test piece (ring) subjected to sandblasting treatment in advance. After the test piece was dried for 10 minutes at 80° C., the test piece was baked for 30 minutes at 240° C. to obtain a test piece for testing.

Evaluation Method

[0050]Sliding tests were performed under the following conditions using a block-on-ring tester (LFW-1 tester), and the number of cycles until the coefficient of friction increased sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com