Cam follower roller device

a follower roller and roller technology, applied in the direction of mechanical equipment, machines/engines, fuel injecting pumps, etc., can solve the problems of limited frictional torque of the device, limited roller and body, and wear generated by axial contact between the friction element or elements, etc., to achieve easy manufacture and assembly, and reduce frictional torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

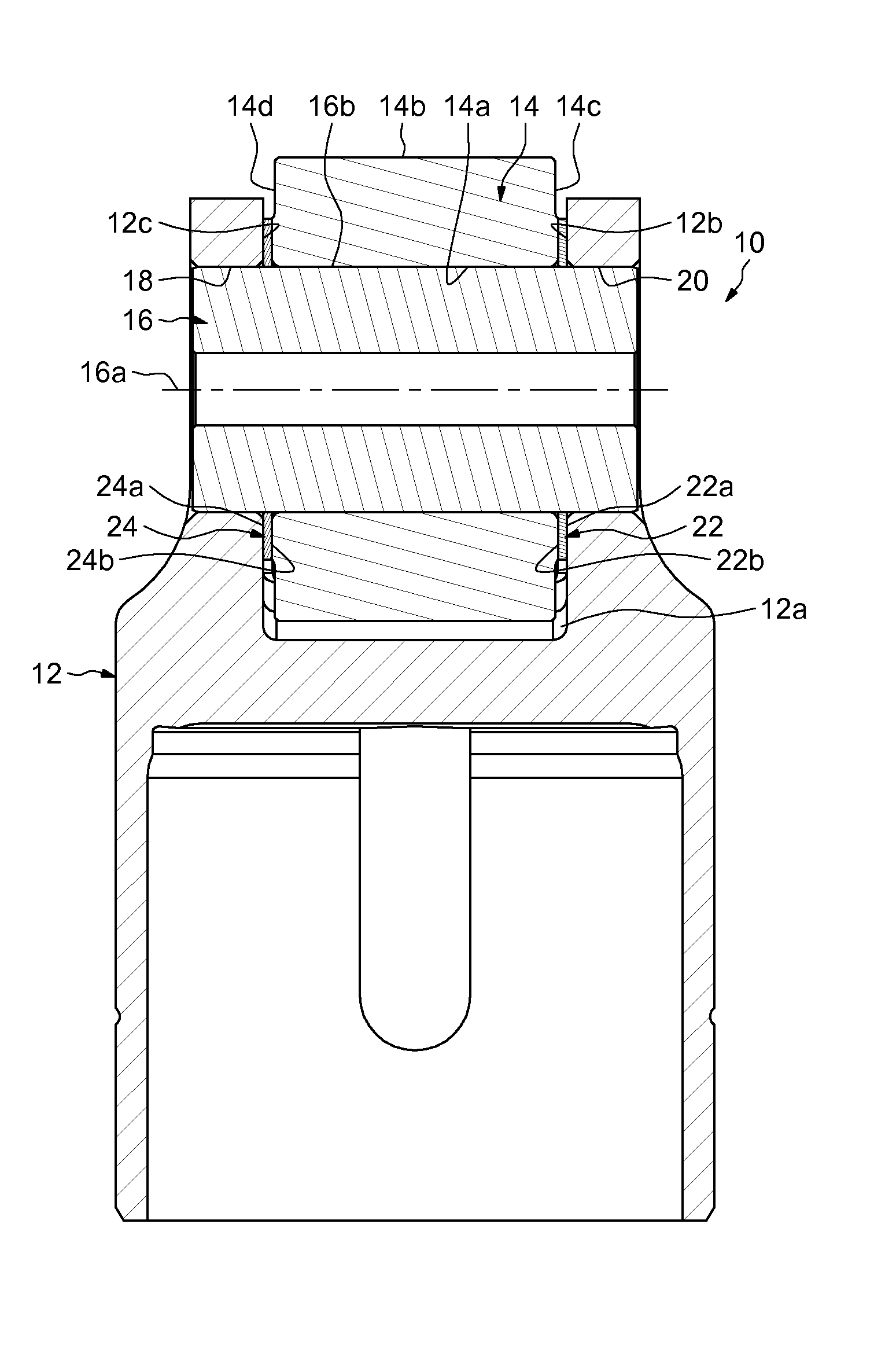

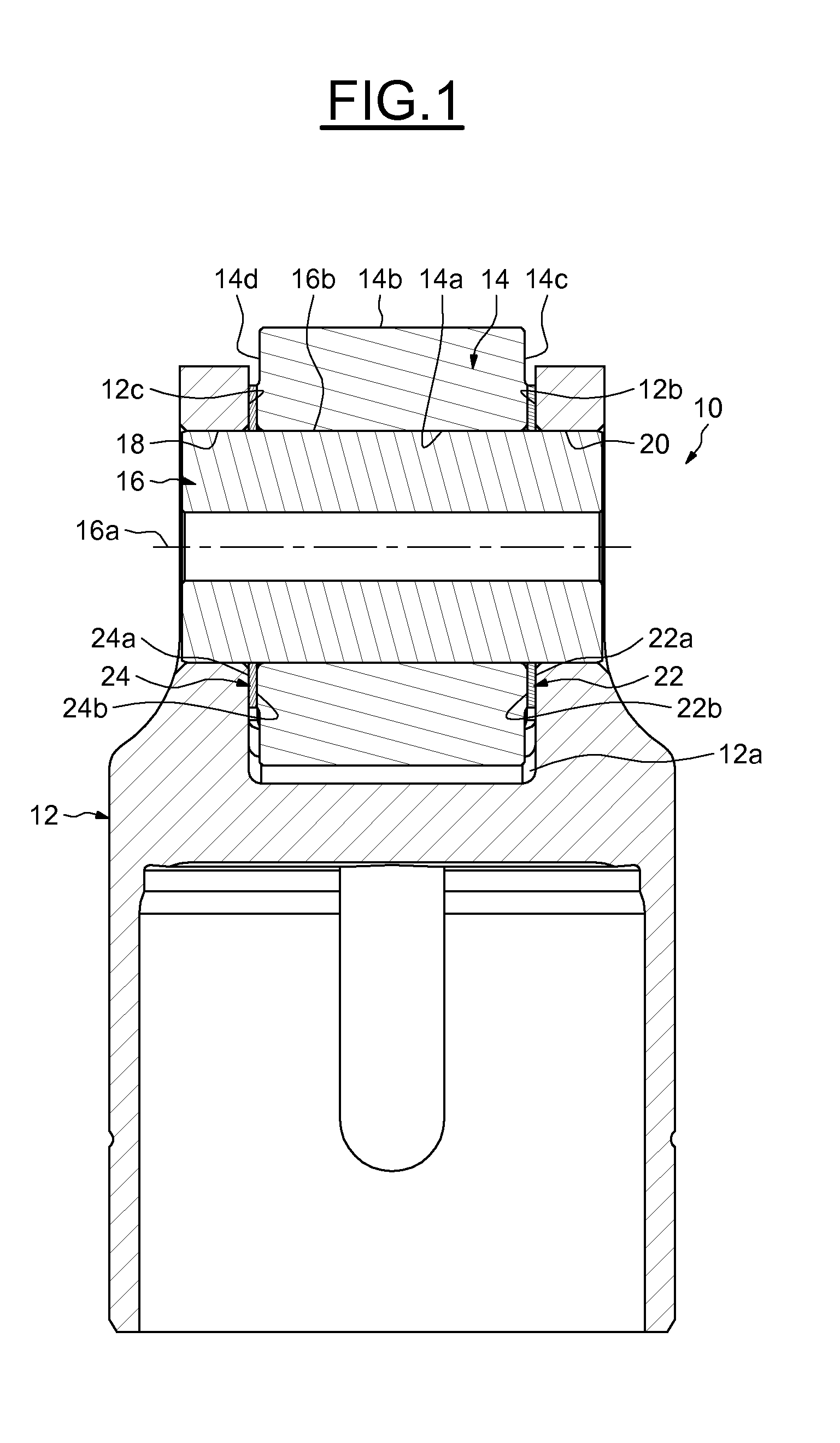

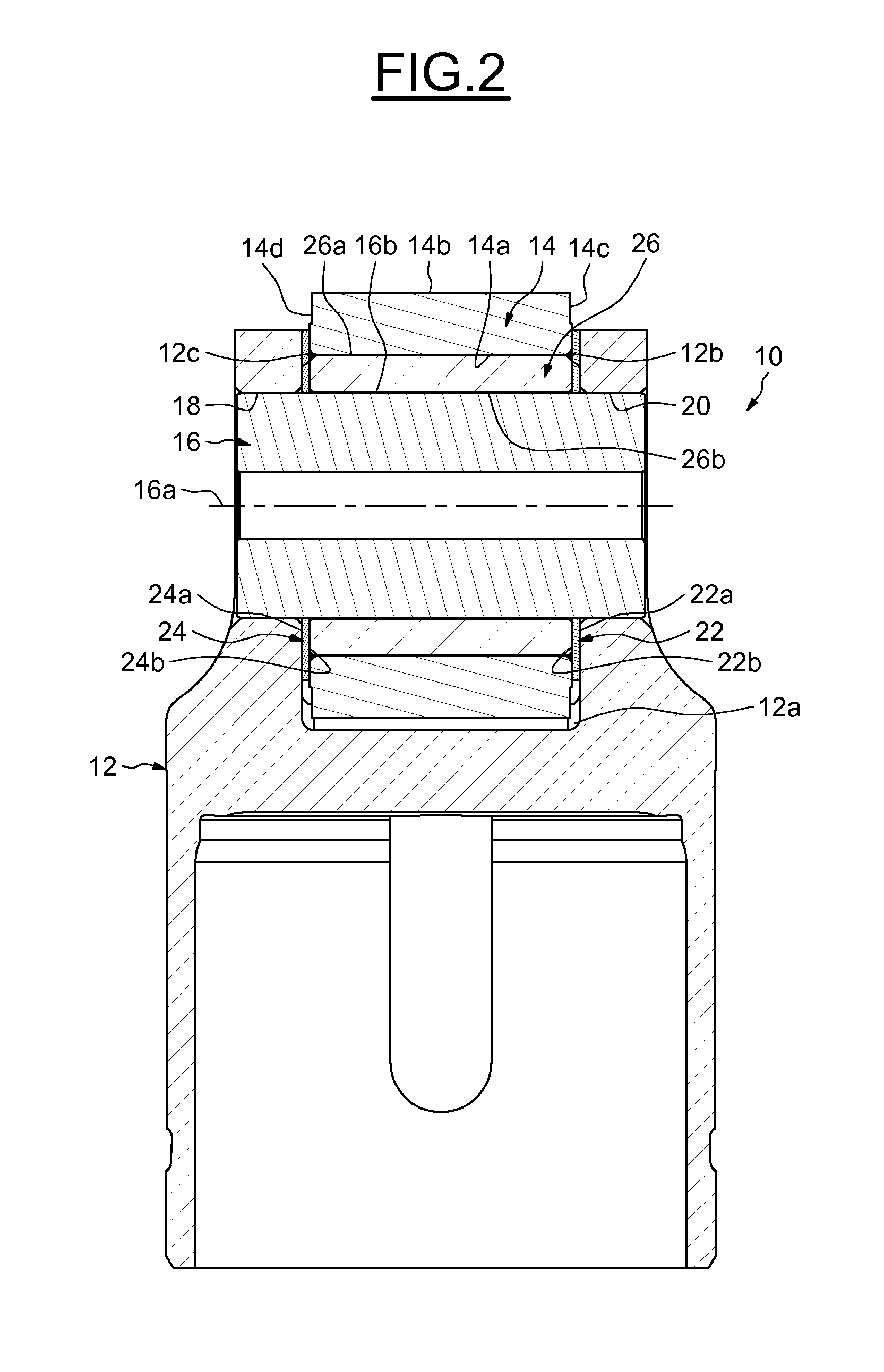

[0024]FIG. 1 shows a cam follower roller device, designated by the general reference number 10, which can for example be used in a fuel injection pump intended for an internal combustion engine.

[0025]The device 10 comprises a tappet or body 12 and a roller 14 mounted to rotate with respect to the body and intended to bear against a cam synchronized with the camshaft of the internal combustion engine or directly against a cam of the shaft. The body 12 delimits an outwardly open recess 12a inside which the roller 14 is mounted. The body 12 comprises two opposed radial front inner walls 12b, 12c axially delimiting the recess 12a. The roller 14 extends so as to project radially outside the body 12. The body 12 may advantageously be obtained at low cost by forging or by cutting, stamping and bending from a blank of thin metal sheet.

[0026]The device 10 also comprises a shaft 16, of geometric axis 16a, mounted on the body 12 and supporting the roller 14. The support shaft 16 comprises an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com