Optical element with high scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

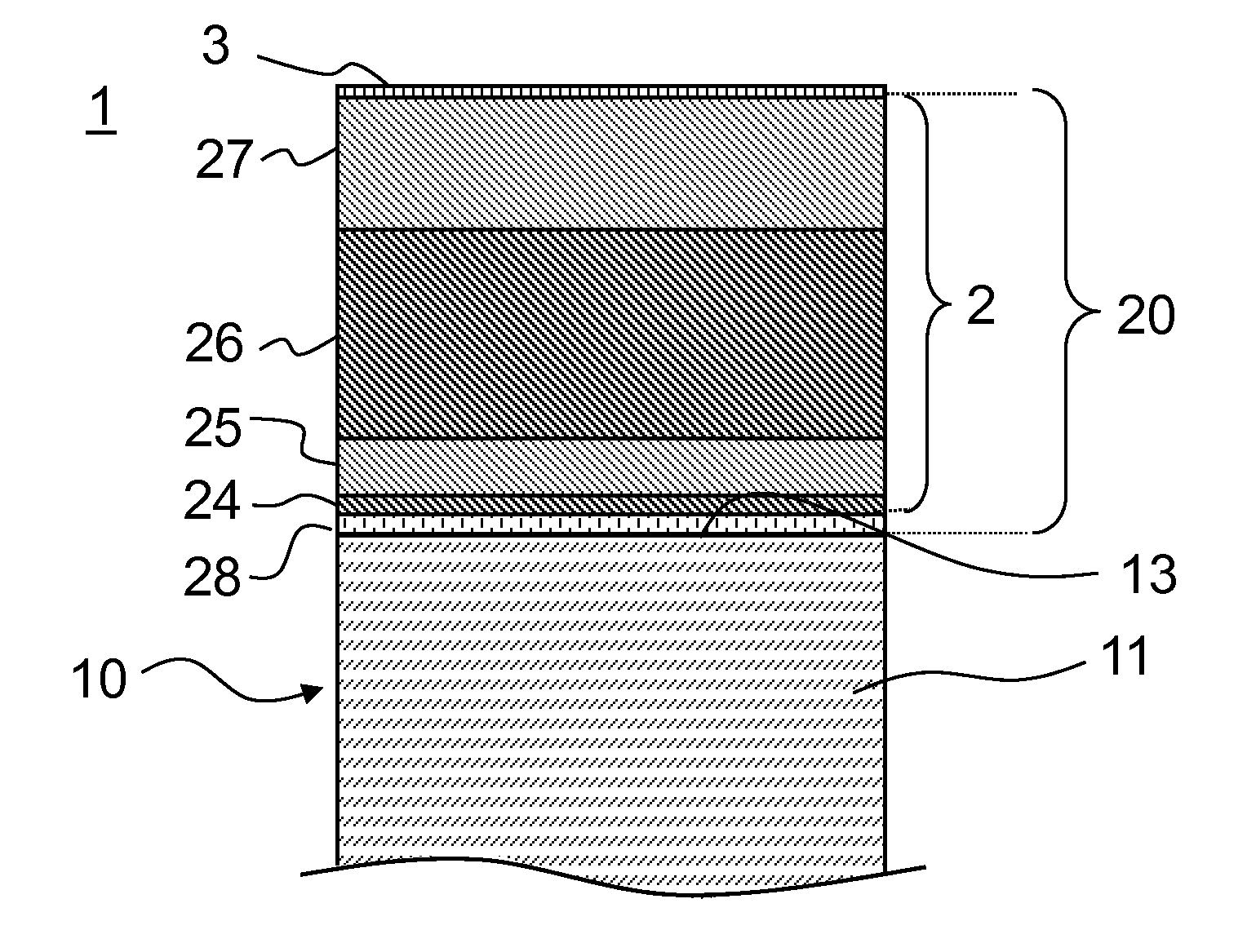

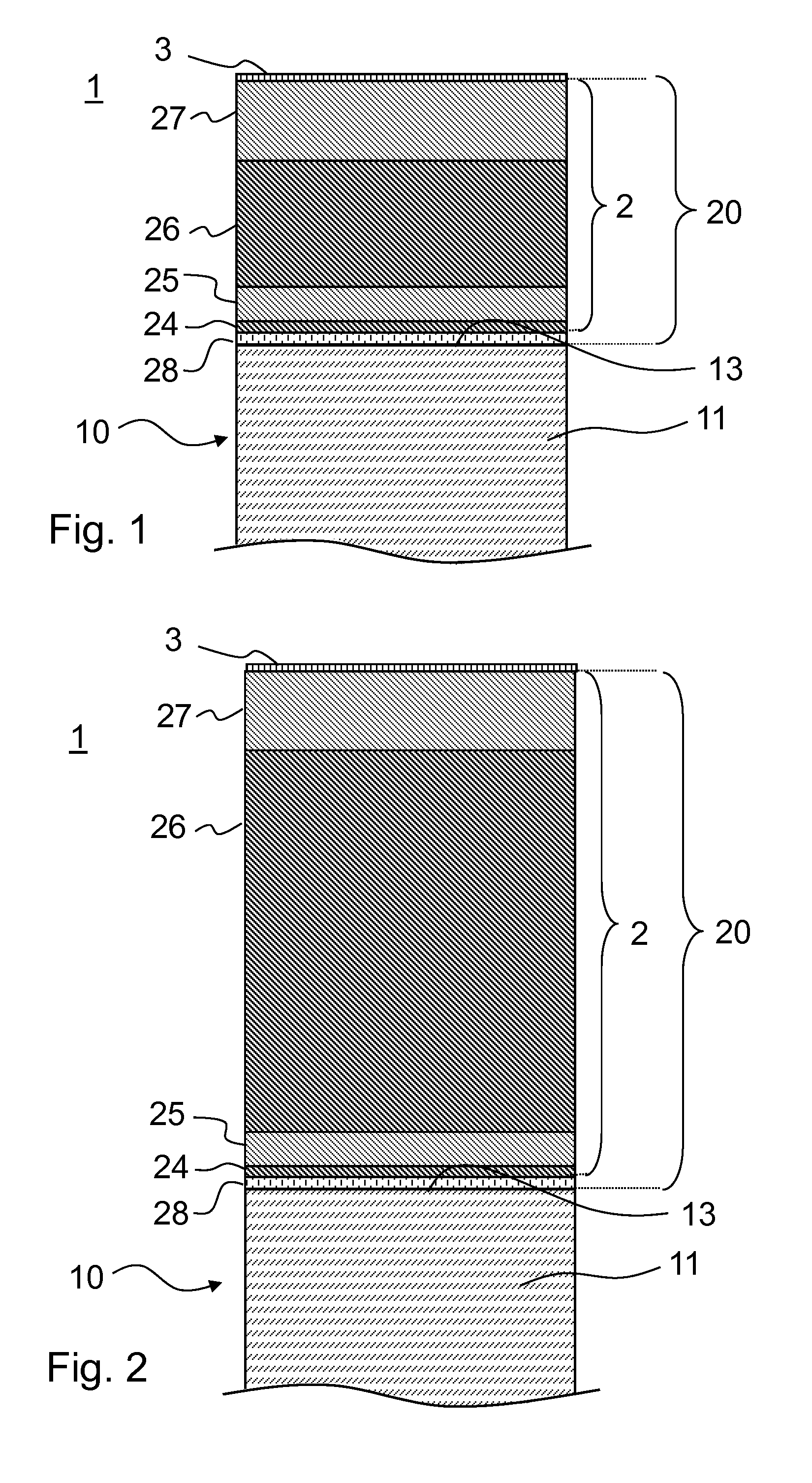

[0028]FIG. 1 and FIG. 2 show examples of optical elements 1 according to the invention with high scratch resistance, having a transparent substrate 10 in the visible spectral region, and a multilayer anti-reflection coating 2 deposited on the substrate 10. Layers 25, 27 of the anti-reflection coating 2 having a first refractive index alternate with layers 24, 26 having a second, higher refractive index in comparison to the first refractive index.

[0029]A layer 3 of chain-form organofluoro molecules is disposed on the uppermost layer 27 of the anti-reflection coating, wherein the molecules are bonded at their ends to the surface of the uppermost layer 27 of the anti-reflection coating 2.

[0030]The organofluoro molecules preferably contain perfluorinated carbon chains, in which all hydrogen atoms, in particular, can also be replaced by fluorine atoms. In addition, the organofluoro molecules are preferably individually covalent at the surface of the optical element 1. The individual mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com