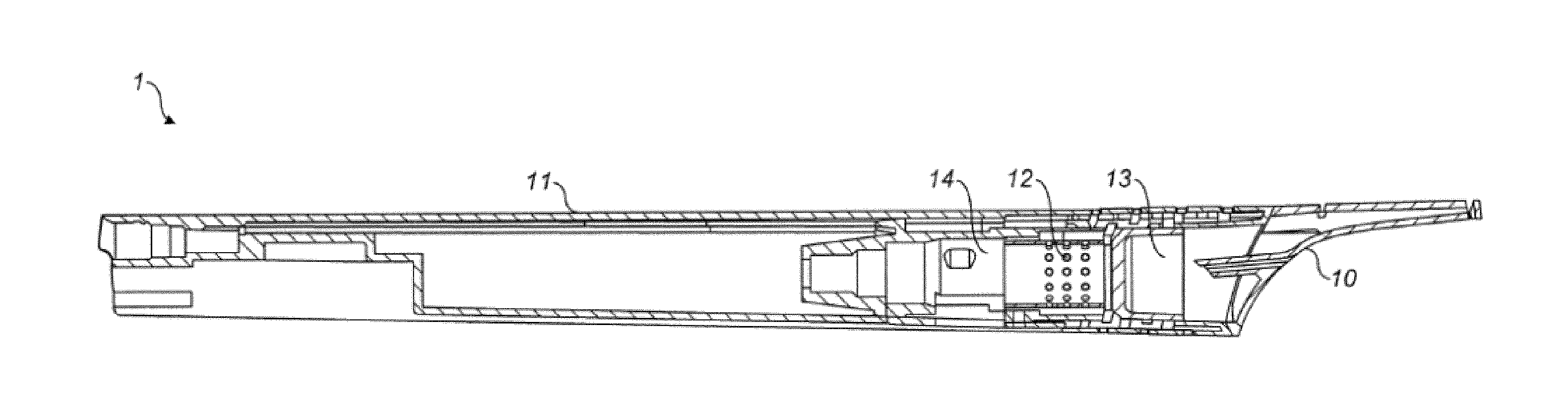

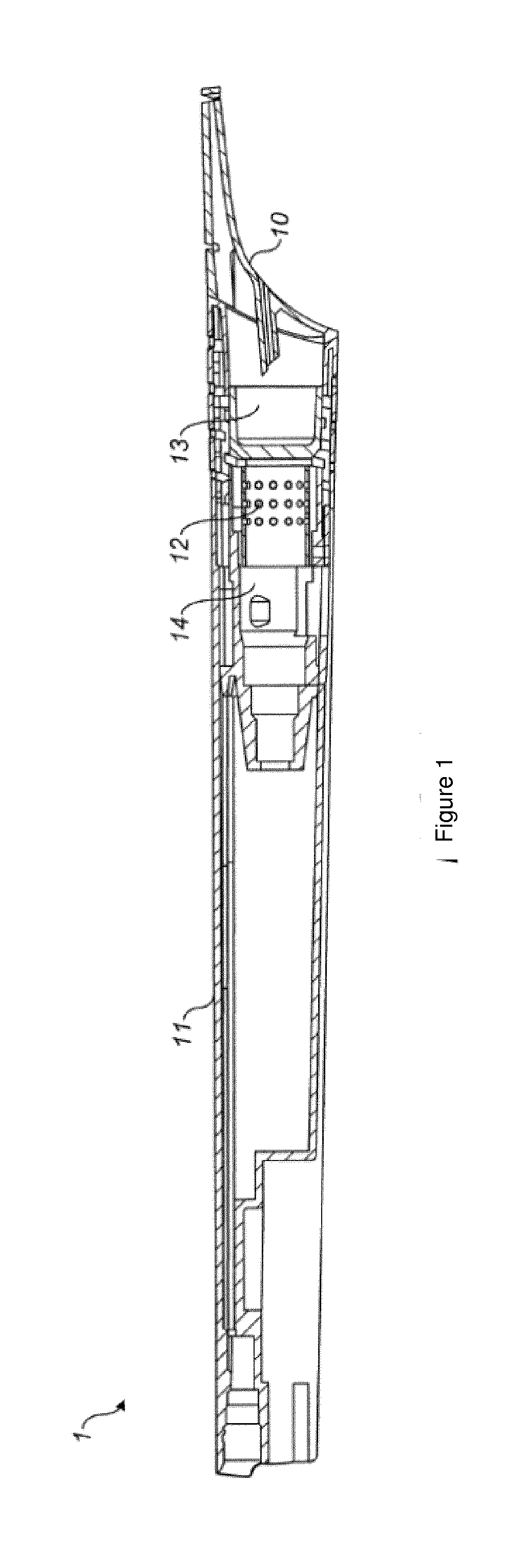

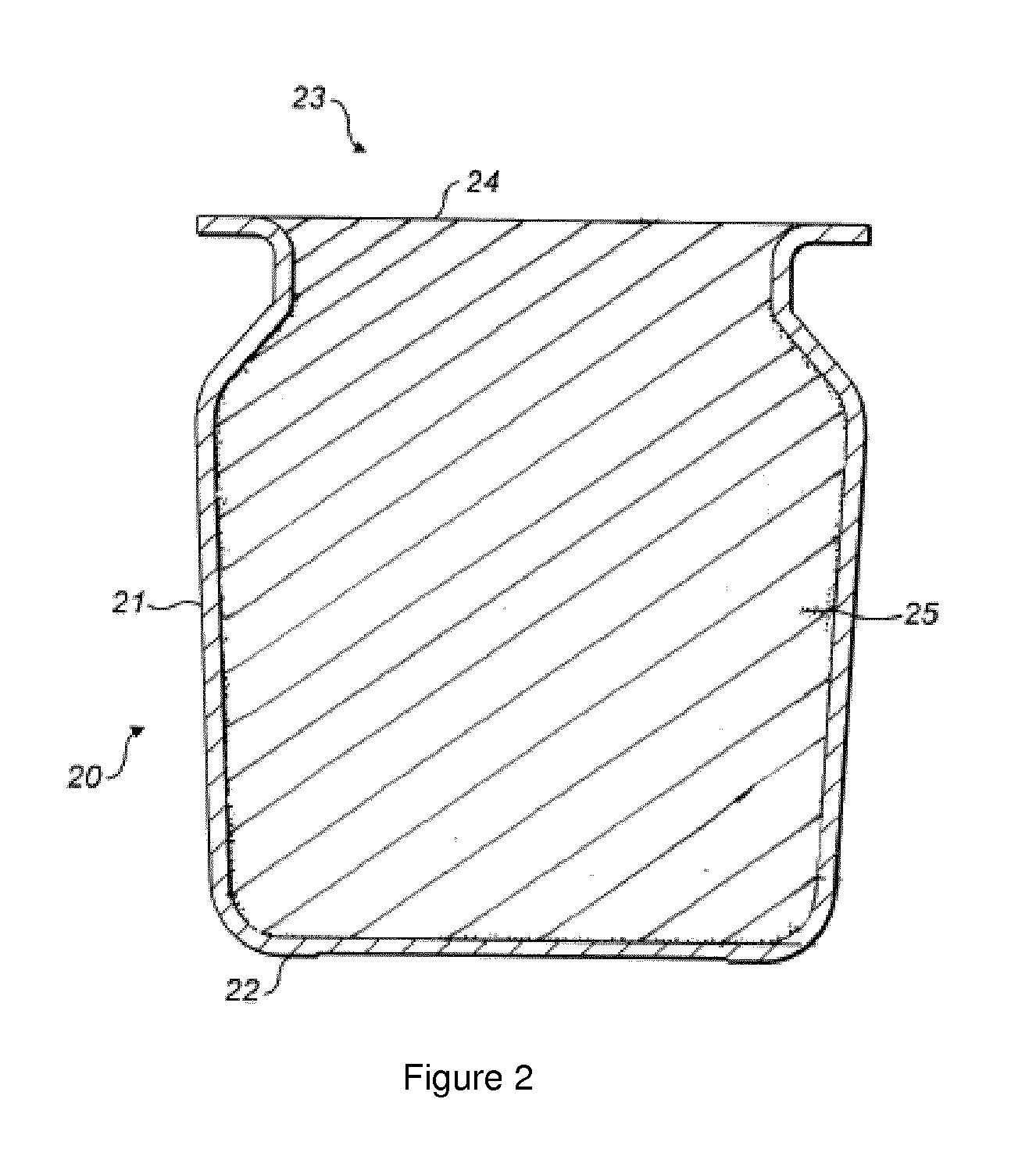

Vaporisable Material and Capsule

a technology of vaporisable materials and capsules, which is applied in the direction of medical atomisers, inhalators, tobacco, etc., can solve the problems of inconsistency of flavour delivery to users and popularity with consumers, and achieve the effect of reducing the particle size of plant fibres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0054]The effect of preparing vaporisable material comprising tobacco fibres of different particle sizes was investigated by the inventors. The consistency of release of compounds (propylene glycol (PG) and total particulate matter (TPM)) during smoking was compared for a range of products comprising plant fibres of different particle sizes.

[0055]Test samples were prepared as shown in Table 4:

TABLE 4SampleParticle size (mm)ABCDEFGHI0.85-0.600%50%50%50%10%10%10%20%10%0.60-0.400%50%0%0%20%20%50%30%30%0.40-0.2550%0%50%0%20%50%30%30%30%50%0%0%50%50%20%10%20%30%

[0056]A negative control sample (sample J) was prepared as shown in Table 5:

TABLE 5Particle size (mm)Sample J (control)2.5-1.6100% 0.85-0.600%0.60-0.400%0.40-0.250%0%

[0057]PG yield was analysed by gas chromatography using a flame ionization detector (GC-FID). The methodology used is similar to ISO10315, which is the standard protocol for gas-chromatographic determination of nicotine in cigarette smoke condensates. Details of ISO10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com