Method and device for setting the oscillation amplitudes of oscillating firing systems for treatment or synthesis of material

a technology of firing system and oscillating amplitude, which is applied in the direction of lighting and heating apparatus, combustion types, combustion processes, etc., can solve the problems of significant increase in mechanical and/or thermal load of the plant structure, increased noise emission from the combustion process to the plant environment, and significant problem for occupational safety and reasonable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

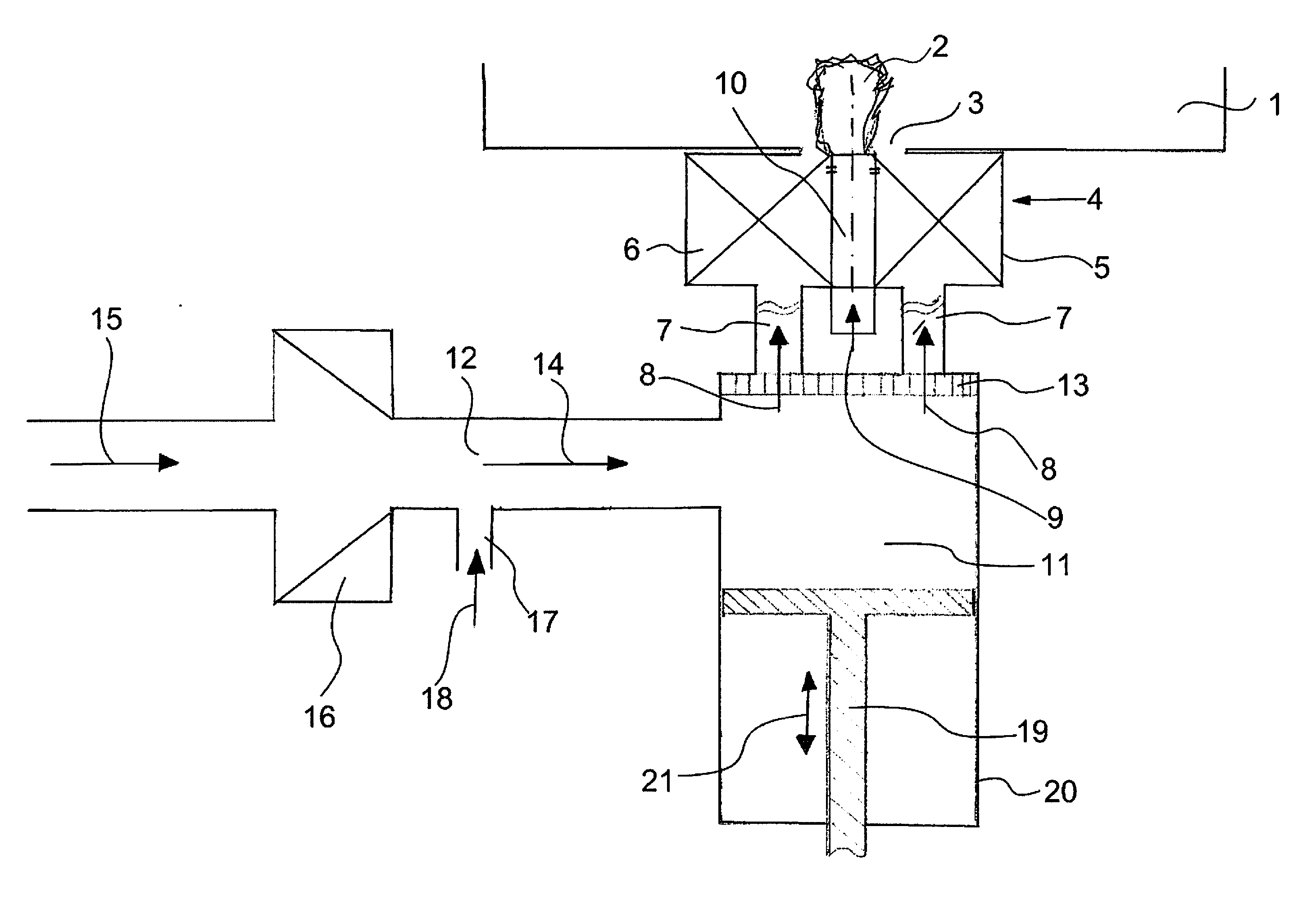

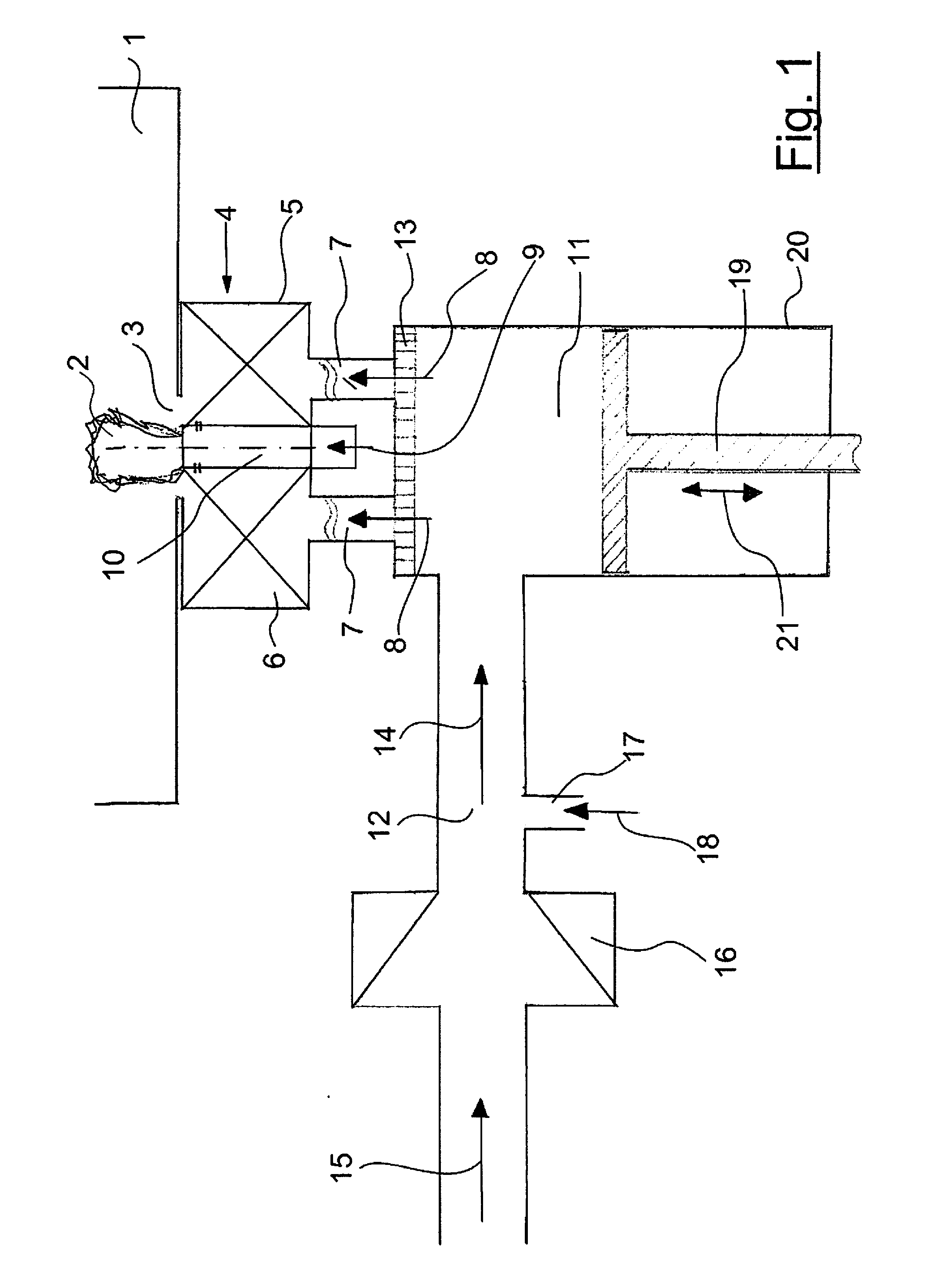

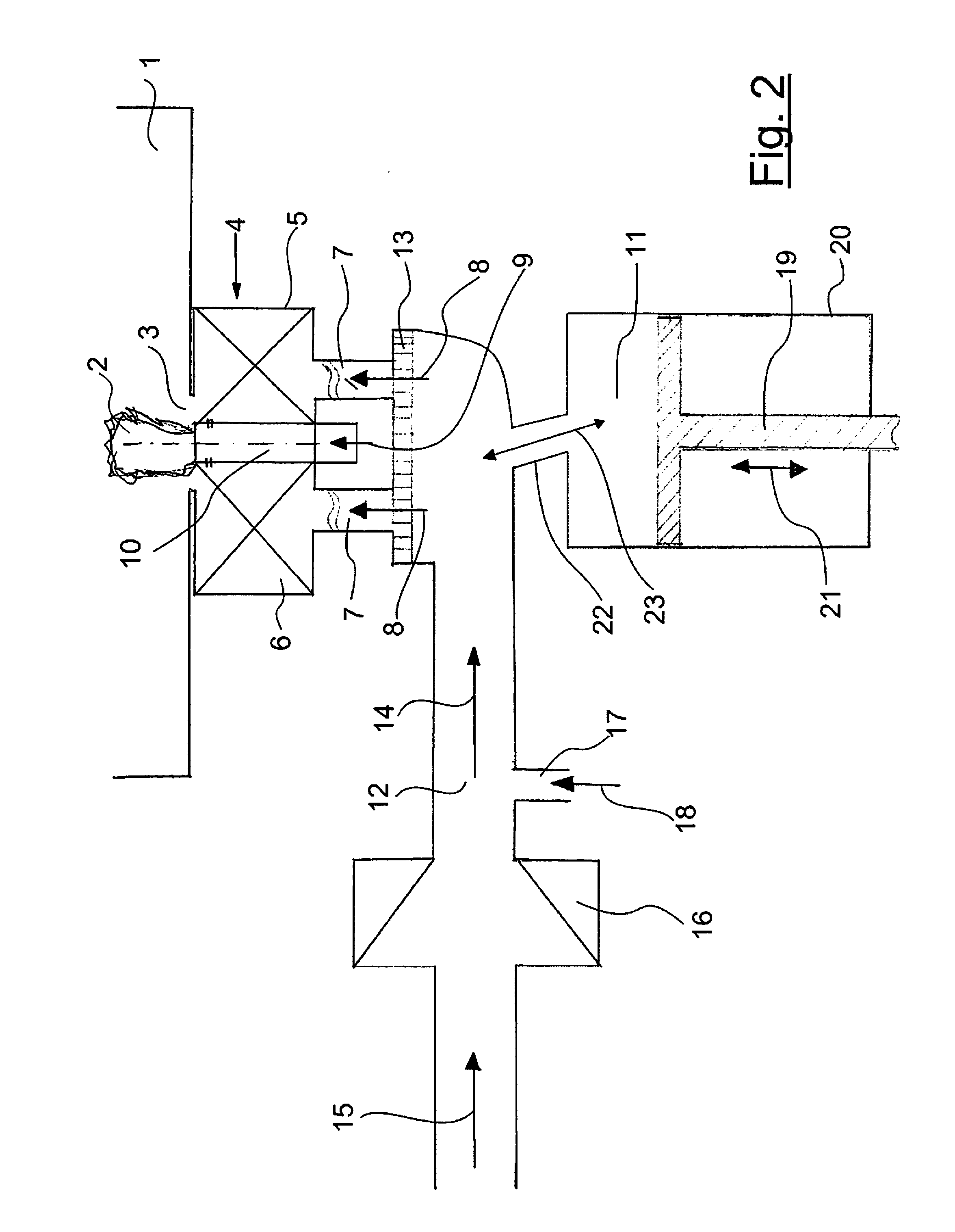

[0063]FIG. 1 shows a schematic diagram of a device according to an embodiment.

[0064]A combustion chamber 1 can be seen here, into which a flame 2 is directed.

[0065]The flame 2 forms at a burner outlet 3 of a burner 4. The flow-technical or fluidical sections of the device lying upstream of the burner outlet of the device are considered a cold side of the burner.

[0066]The flame 2 pulsates and causes a pulsation of an existing plant-specific resonating gas column being in the combustion chamber and / or in a reactor chamber downstream of this reactor chamber. Into this combustion chamber or the reactor chamber, a reactant is fed, that then is treated in the oscillating gas column of hot gas, and finally the product thus produced is removed from the hot gas stream, for example, by a hot gas filter, a cyclone or the like.

[0067]The pulsation of the flame 2 is a self-excited combustion instability, wherein the frequency of their self-excited oscillation is determined in large part by the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com