System and method for liquefaction of natural gas

a natural gas and liquefaction technology, applied in the field of systems and methods for liquefaction of natural gas, can solve the problems of increasing the initial cost and running limited power produced by the expander, and insufficient to increase the outlet pressure, so as to achieve the effect of increasing the outlet pressure of the compressor and reducing the operating cost of the cooling uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

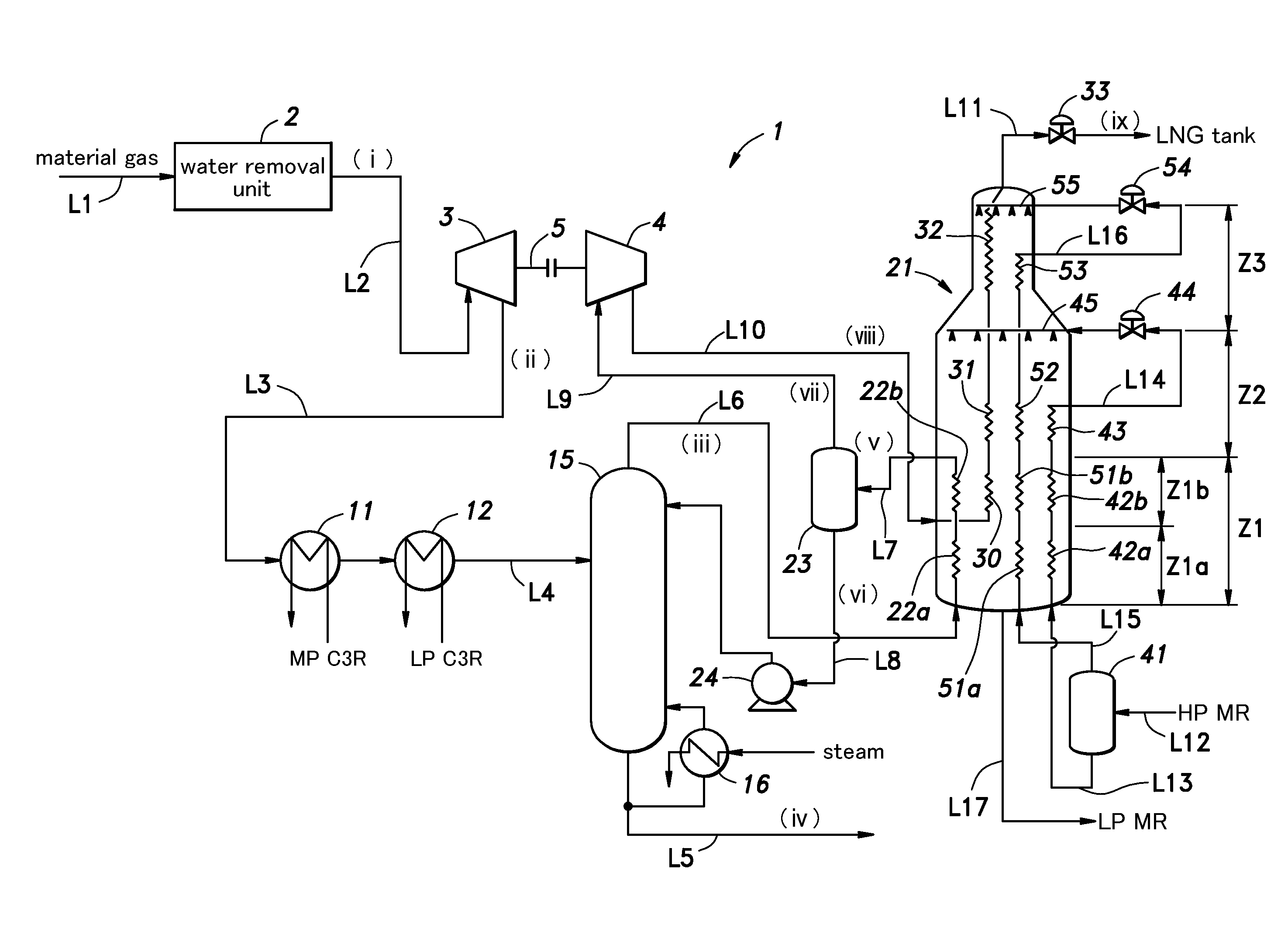

[0096]FIG. 1 is a diagram showing a liquefaction process flow in a system for the liquefaction of natural gas given as a first embodiment of the present invention. Table 1 which will be shown hereinafter lists the results of a simulation of the liquefaction process in the system for the liquefaction of natural gas. The same is similarly true with Tables 2 to 12. Table 1 shows the temperature, the pressure, the flow rate and the molar composition of the natural gas that is to be liquefied at each of various points in the liquefaction system of the first embodiment. In Table 1, columns (i) to (ix) show the values at the respective points in the liquefaction system 1 denoted with corresponding roman numerals (i) to (ix) in FIG. 1.

[0097]Natural gas containing about 80 to 98 mol % of methane is used as the material gas or the feedstock gas. The material gas also contains at least C5+ hydrocarbons by at least 0.1 mol % or BTX (benzene, toluene, xylene) by at least 1 ppm mol as heavier con...

second examples

(First and Second Examples for Comparison)

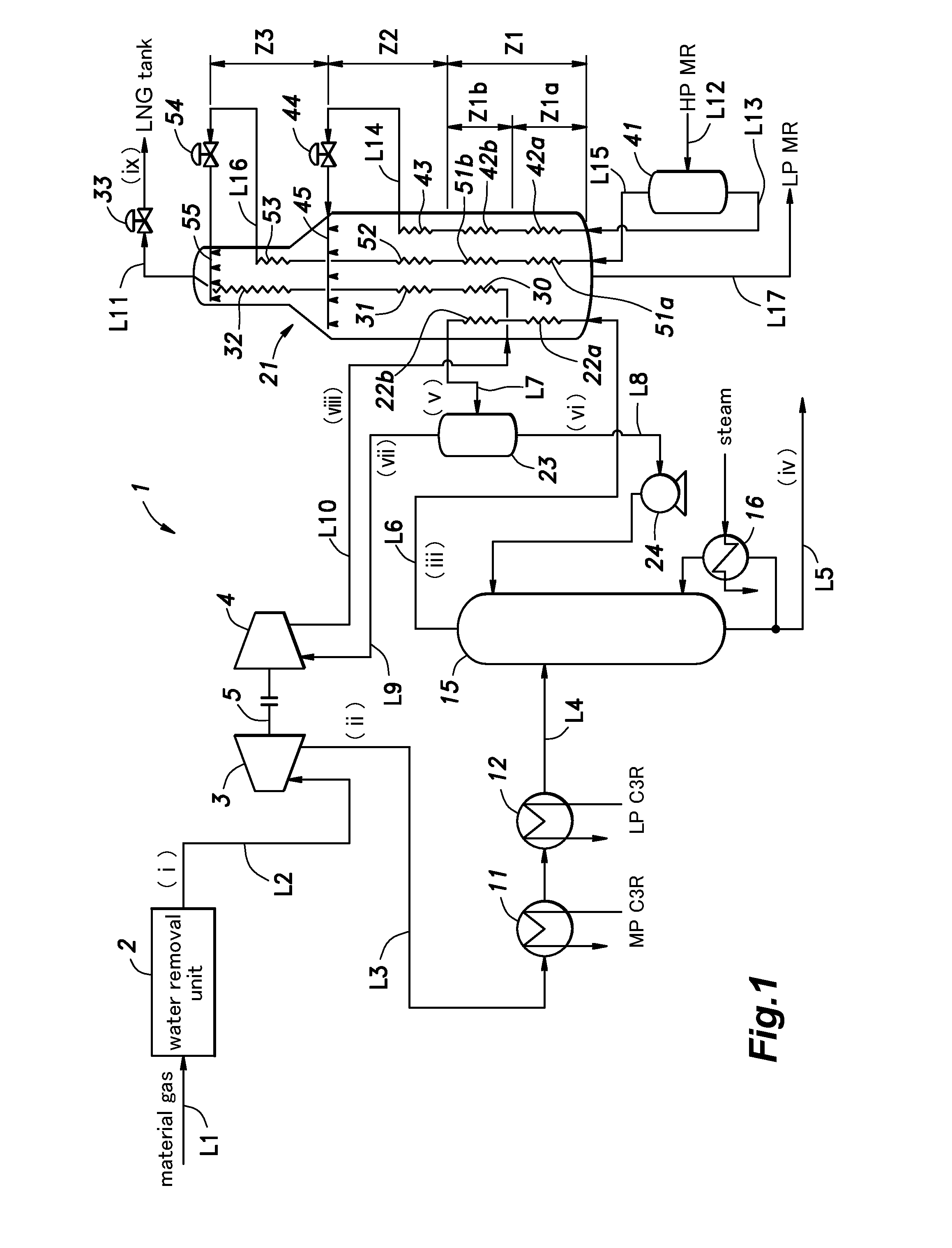

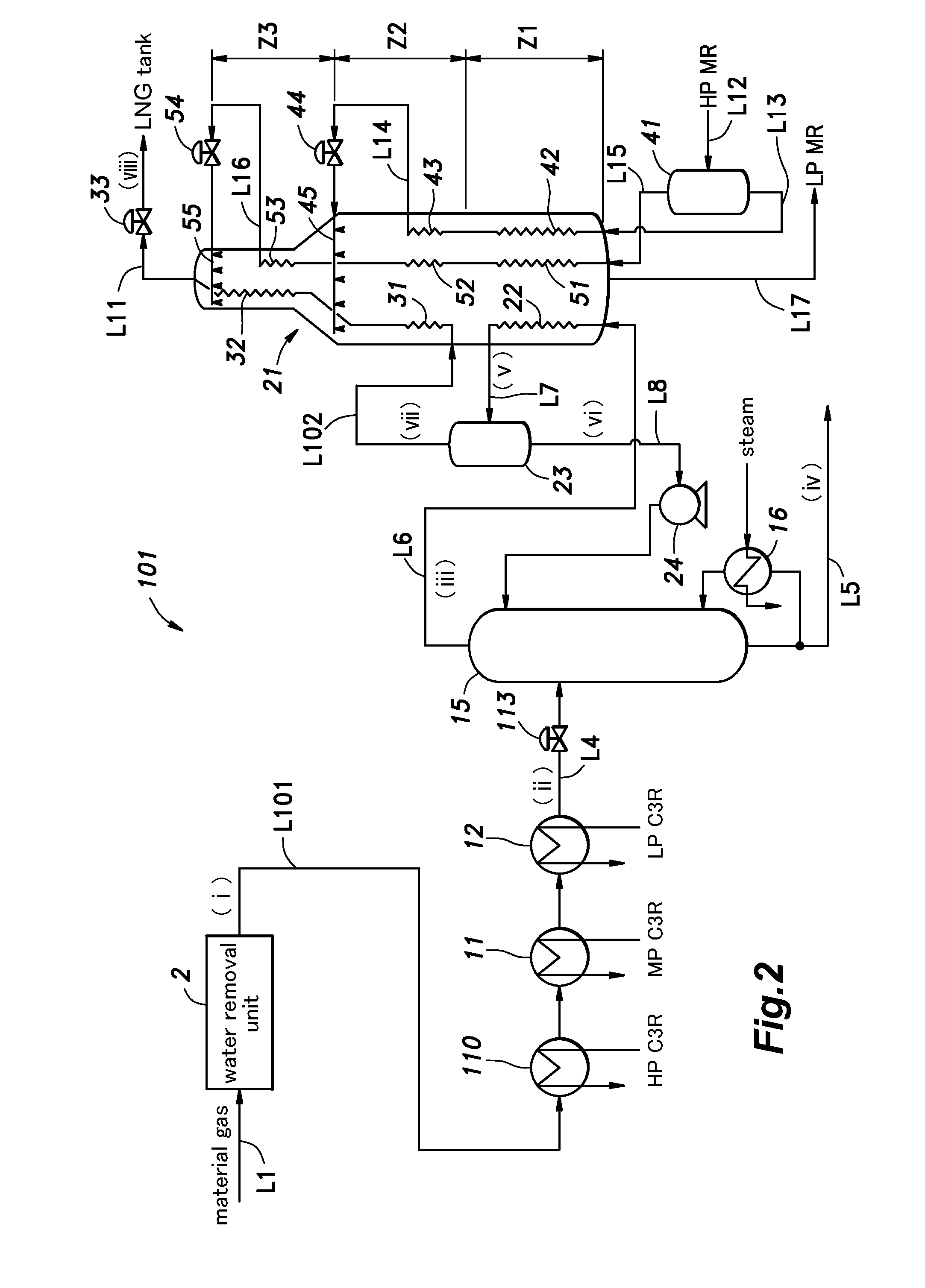

[0118]FIGS. 2 and 3 are diagrams showing liquefaction process flows in conventional systems for the liquefaction of natural gas given as a first and a second example for comparison with the first embodiment of the present invention. In the conventional liquefaction systems 101 and 201 for natural gas, the parts corresponding to those of the liquefaction system of the first embodiment are denoted with like numerals. Tables 2 and 3 show the temperature, pressure, flow rate and molar fractions of the material gas in the liquefaction systems of the first and second examples for comparison, respectively. It should be noted that the liquefaction system 201 of the second example for comparison is based on the prior art disclosed in Patent Document 1 (U.S. Pat. No. 4,065,278).

[0119]As shown in FIG. 2, the liquefaction system 101 of the first example for comparison is not provided with the first expander 3 and the first compressor 4 used in the lique...

second embodiment

[0148]FIG. 11 is a diagram showing a liquefaction process flow in a system for the liquefaction of natural gas given as a second embodiment of the present invention. Table 7 shows the temperature, the pressure, the flow rate and the molar composition of the natural gas that is to be liquefied at each of various points in the liquefaction system of the second embodiment by way of an example. In the liquefaction system illustrated in FIG. 11, the parts corresponding to those of the liquefaction system 1 of the first embodiment are denoted with like numerals and omitted from the following discussion except for the matters that will be discussed in the following.

[0149]The liquefaction system 1 of the second embodiment further includes a fourth compressor 71 for gas supply and a fourth cooler 72 on the upstream end of the line L1 for supplying the material gas to the water removal unit 2. In this liquefaction system 1, the material gas supplied from a line L18 is compressed by the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com