DC plasma torch electrical power design method and apparatus

a plasma torch and electrical power technology, applied in the direction of plasma techniques, electrical devices, spark plugs, etc., can solve the problems of increasing raw material costs and energy resources, which are a substantial part of the cost of most if not all manufacturing processes, and achieve the effect of reducing voltage fluctuations, no arc extinguishing, and more stable operation of the torch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

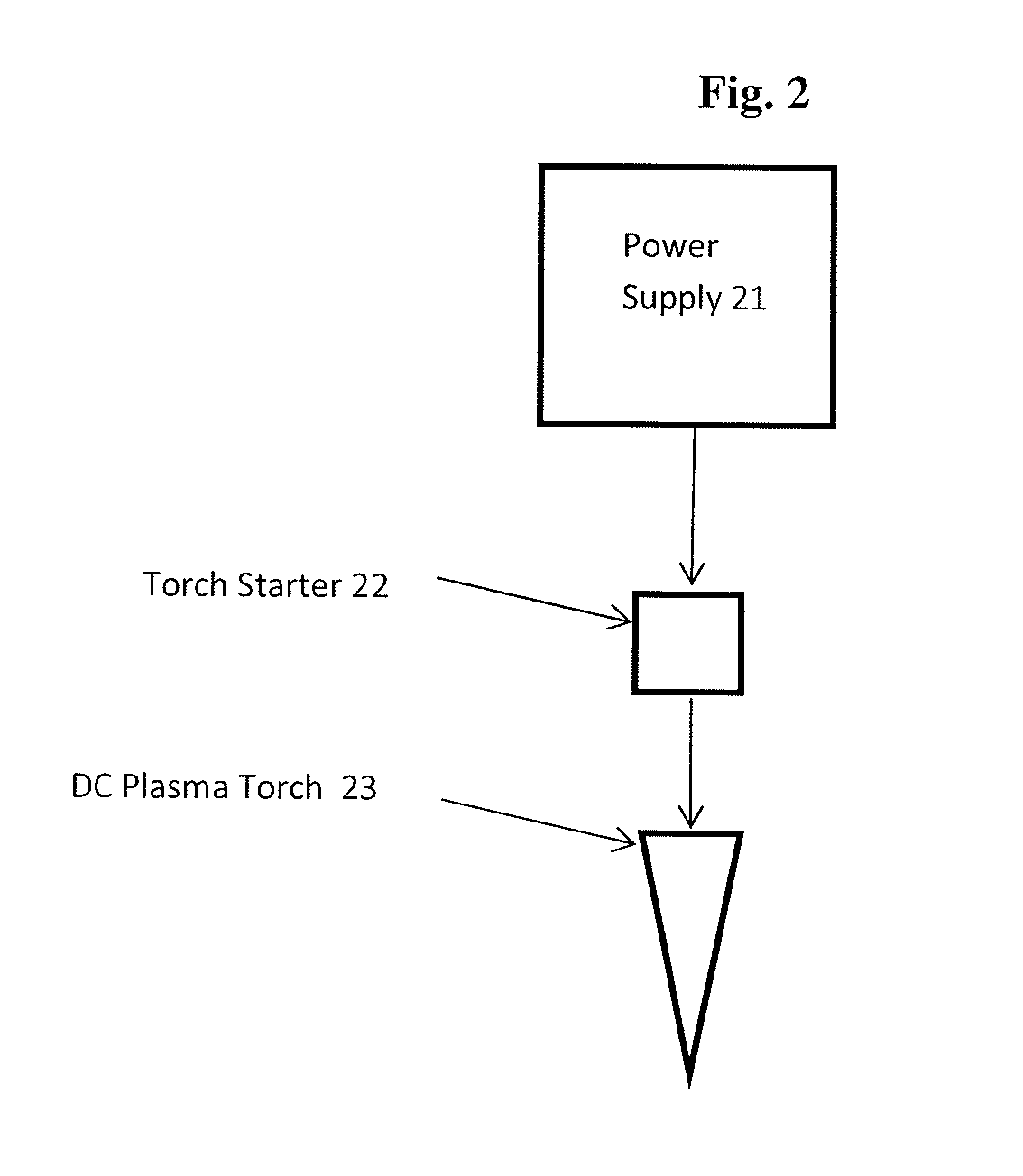

[0032]A DC concentric cylinder, graphite electrode, plasma torch is operated using an average operating voltage of 300-500 volts. The power supply to operate the plasma torch has a voltage generating capability of at least two times the average operating voltage needed, i.e. 1000 volts. This results in a much more stable operation of the torch as described herein. A separate starter power supply also has the capability of igniting the torch at a pulse voltage of at least 20 kilovolts. The starter power supply contains an appropriate amount of capacitive filtering to shunt unwanted energy away from sensitive electronic components.

example 2

[0033]A topology for implementing the system described in Example 1 is as follows. A 6, 12, 18, or 24-pulse rectifier is used as the front end AC-DC converter. This rectifier can be phase-controlled or naturally commutated, with a capacitive output filter, and with or without a commutating output choke. Several chopper regulators composed of power electronic switching devices, snubber circuits, and gating control circuits are used to control the current applied to the load. These chopper regulators can be placed in a parallel configuration to add redundancy, or in a series-parallel configuration to also allow for the use of devices with lower blocking voltages. Smoothing reactors are used as the main energy storage device in the current regulator, and are distributed among the positive and negative legs of the regulator to add additional protection for the sensitive power electronics. Capacitors are used as filters on the output of the current regulator to absorb high frequency ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com