System and method for dynamic control of a heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

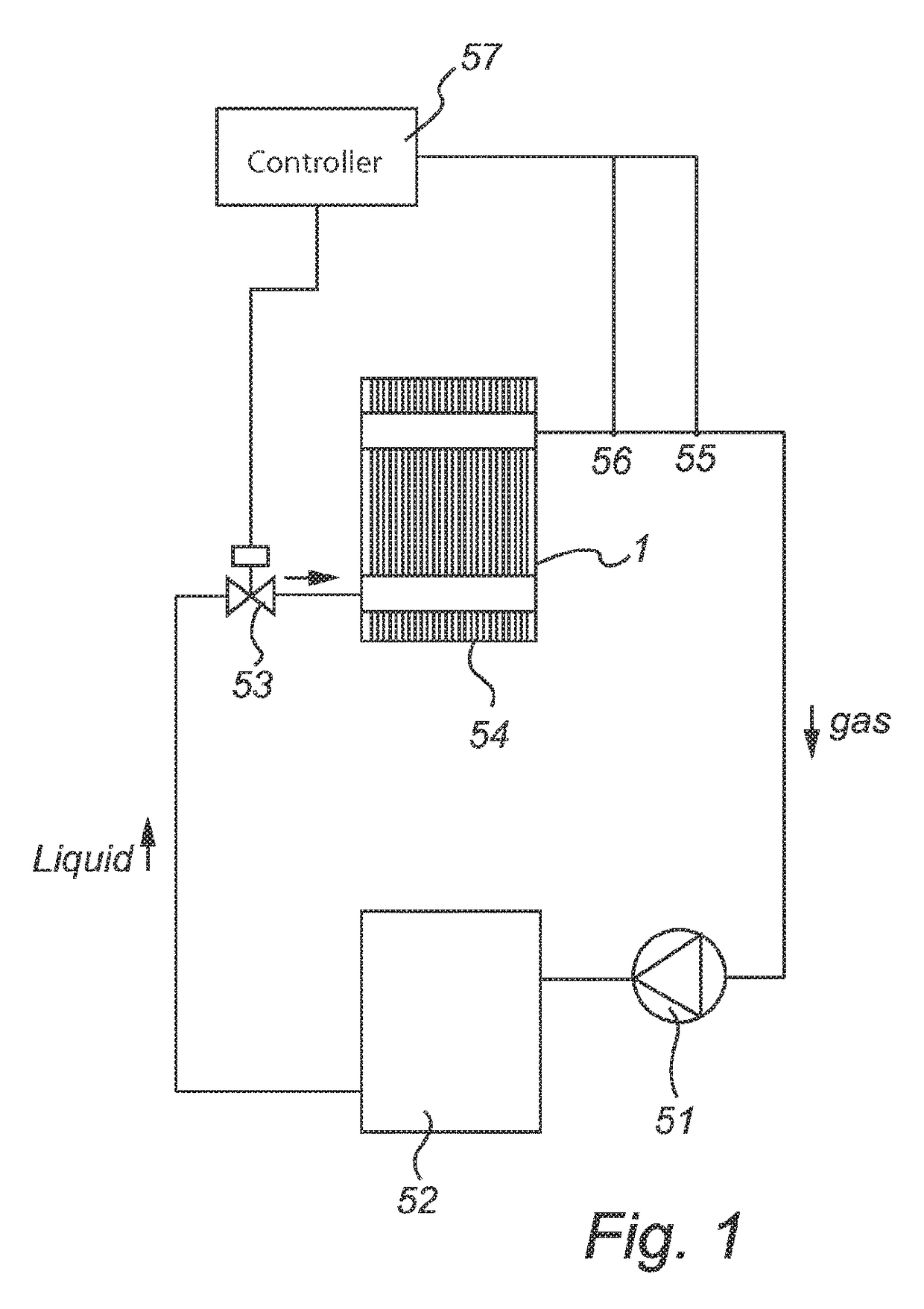

[0075]A heat exchanger 1 may typically be included as an evaporator in a refrigeration circuit. A prior art refrigeration system, see FIG. 1, being a mechanical vapor compression system, typically comprises a compressor 51, a condenser 52, an expansion valve 53 and an evaporator 54. The circuit may further comprise a pressure sensor 55 and a temperature sensor 56 arranged between the outlet of the evaporator and the inlet of the compressor. The refrigeration circle of such system starts when a cooling agent enters the compressor 51 in evaporated form with a low pressure and with a low temperature. The cooling agent is compressed by the compressor 51 to a high pressure and high temperature evaporated state before entering the condenser 52. The condenser 52 precipitates the high pressure and high temperature gas to a high temperature and high pressure liquid by transferring heat to a lower temperature medium, such as water or air. The high temperature liquid then enters the expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com