Aluminum alloy plate having excellent moldability and bake finish hardening properties

a technology of aluminum alloy plate and bake finish hardening, which is applied in the field of al — mg — si alloy sheet, can solve the problems of deterioration of bh response, deterioration of formability into a panel, and cracking of hem working, so as to inhibit the diffusion of mg, improve the formability of press, and inhibit the effect of strength increas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0151]The present invention will be explained below in more detail by reference to Examples. However, the present invention should not, of course, be construed as being limited by the following Examples, and can be suitably modified unless the modifications depart from the gist of the present invention described hereinabove and hereinafter. All such modifications are included in the technical range of the present invention.

(Examples According to the First Aspect)

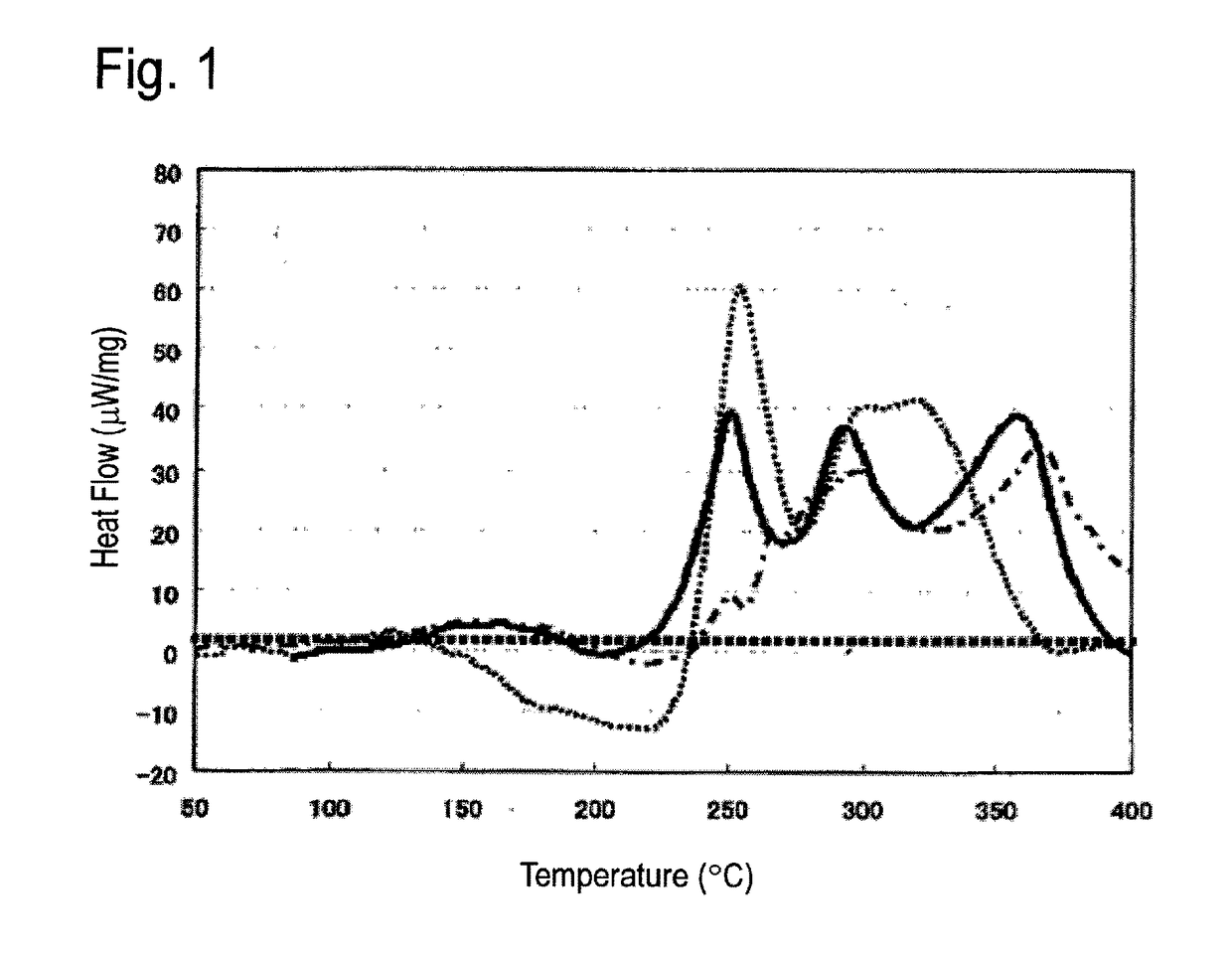

[0152]Next, Examples according to the first aspect of the present invention are explained. 6000-series aluminum alloy sheets were individually produced so as to differ in the structure specified with a DSC in the present aspect, by changing the conditions for a preliminary aging treatment performed after solution and quenching treatments. After a holding at room temperature for 30 days after the production of the sheets, BH response (bake hardenability), As proof stress as an index of press formability and hem workability as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| mass ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com