Method and system for providing auxiliary refrigeration to an air separation plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

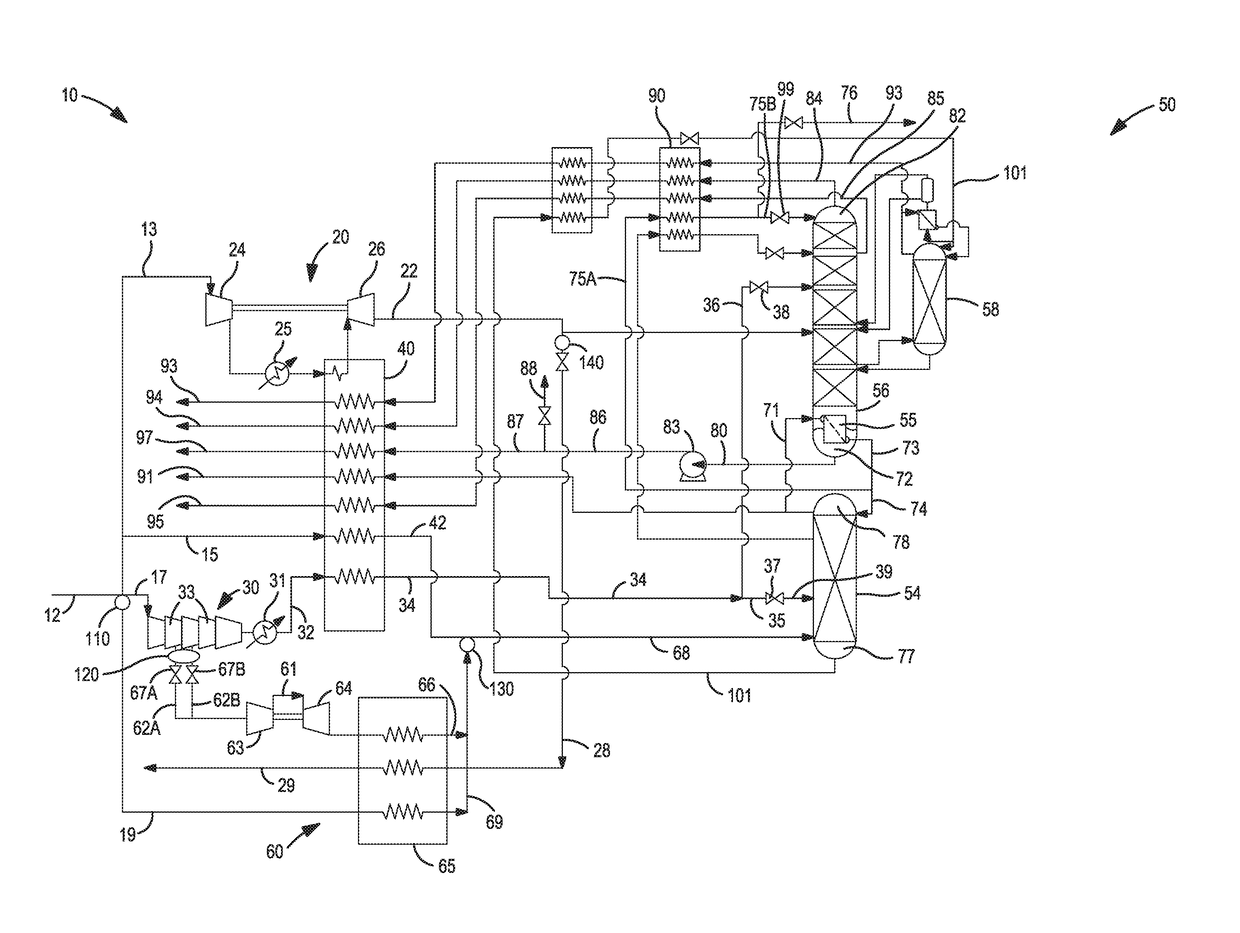

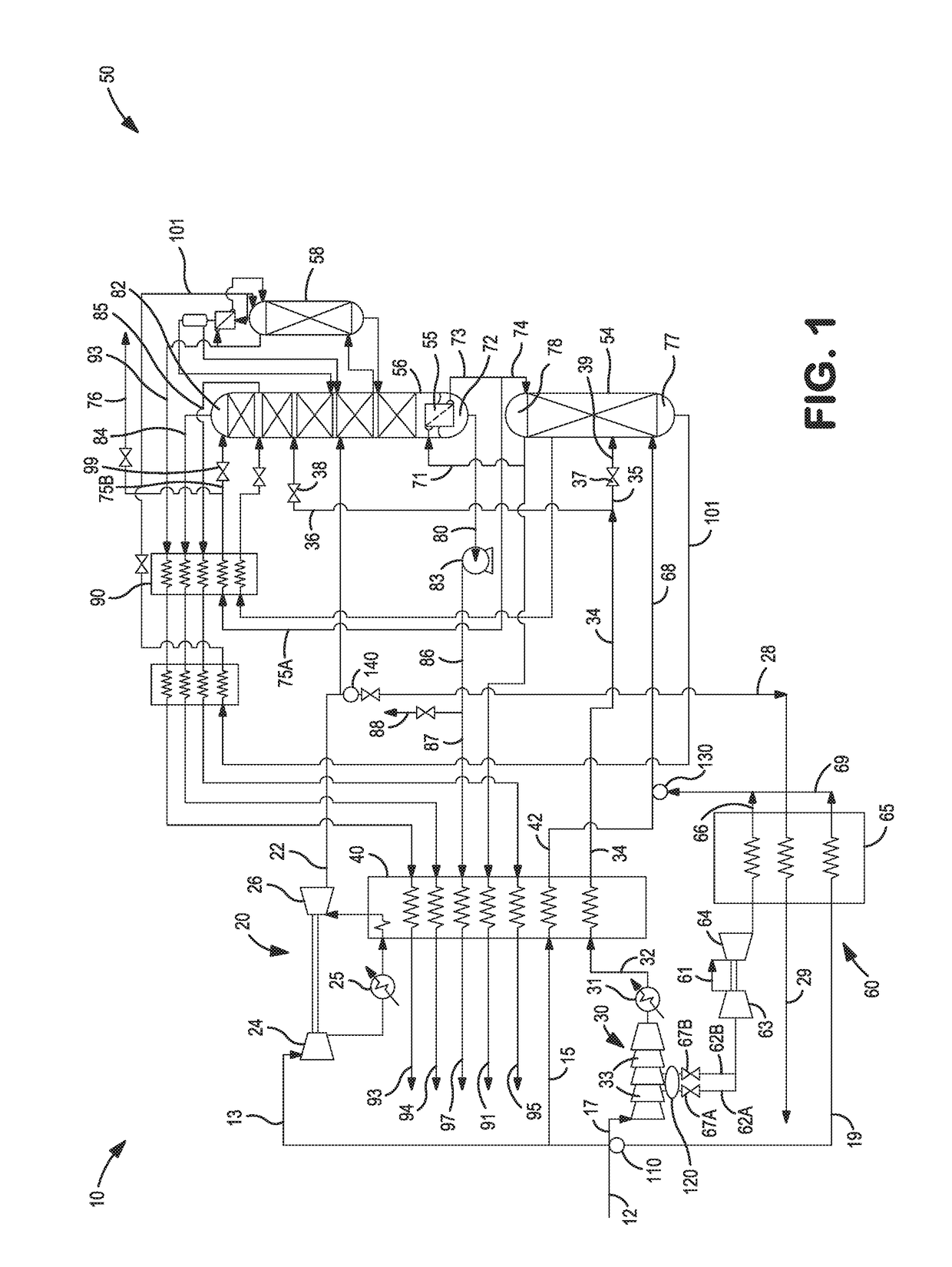

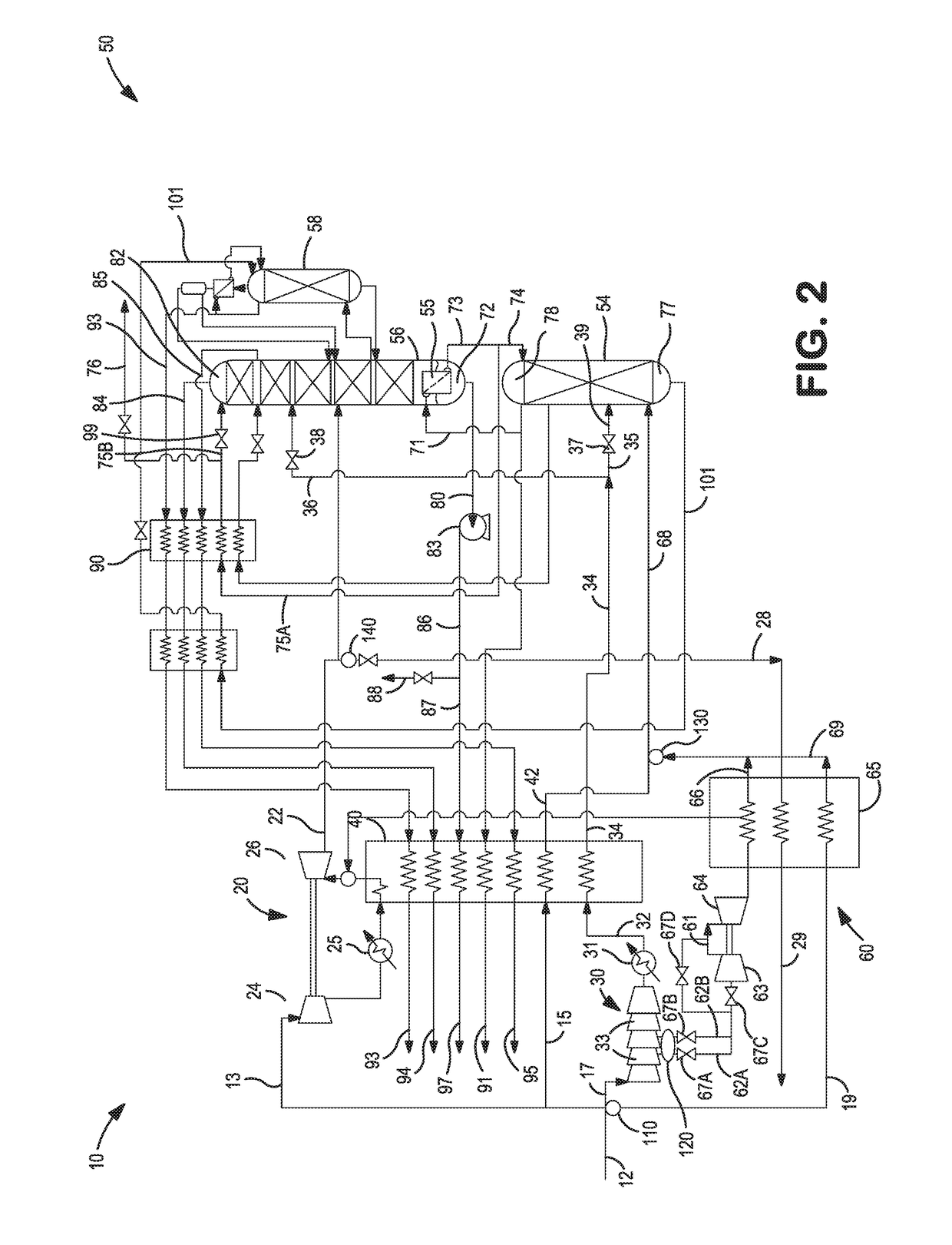

[0013]In reference to FIGS. 1-3, an air separation unit 10 generally includes an incoming air compression and purification train or circuit (not shown); a primary refrigeration circuit 20; a booster air compression train or circuit 30; a main heat exchanger 40; and a distillation column system 50.

[0014]In the incoming air purification and compression train or circuit, the incoming feed air is compressed in a multi-stage, intercooled, main air compressor arrangement to a pressure that can be between about 5 bar(a) and about 15 bar(a). This main air compressor arrangement may be an integrally geared compressor or a direct drive compressor arrangement. The compressed air feed is then purified in a pre-purification unit to remove high boiling contaminants from the incoming feed air. A pre-purification unit, as is well known in the art, typically contains beds of alumina and / or molecular sieve operating in accordance with a temperature and / or pressure swing adsorption cycle in which mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com