Element and electric generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0196]

[0197]—Production of Intermediate Layer—

[0198]Silicone rubber (IVS4312, manufactured by Momentive Performance Materials Inc.) was applied onto a polyethylene terephthalate (PET) film, and the applied silicone rubber composition was heated to cure at 120° C. for 30 minutes, to thereby form a thin film having a thickness of 100 μm.

[0199]Subsequently, the thin film was subjected to a corona discharge treatment under the following conditions. Thereafter, the PET film was peeled. In the manner as described above, an intermediate layer was obtained.

[0200]

[0201]Applied voltage: 100 V

[0202]Cumulative energy: 60 J / cm2

[0203]Reaction atmosphere: air

[0204]—First Electrode and Second Electrode—

[0205]As for each of a first electrode and a second electrode, AL-PET 9-100 (thickness of aluminium foil: 9 μm, thickness of polyethylene terephthalate film: 100 μm (cover material)) manufactured by PANAC CO., LTD. was provided.

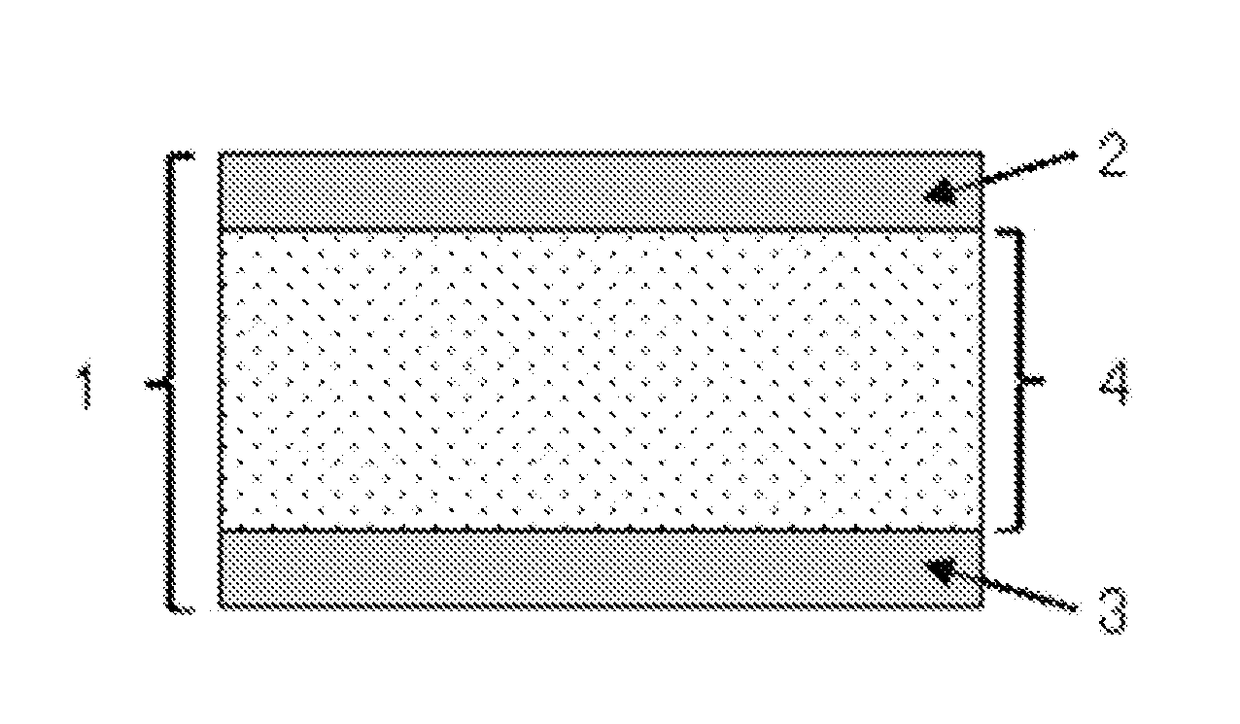

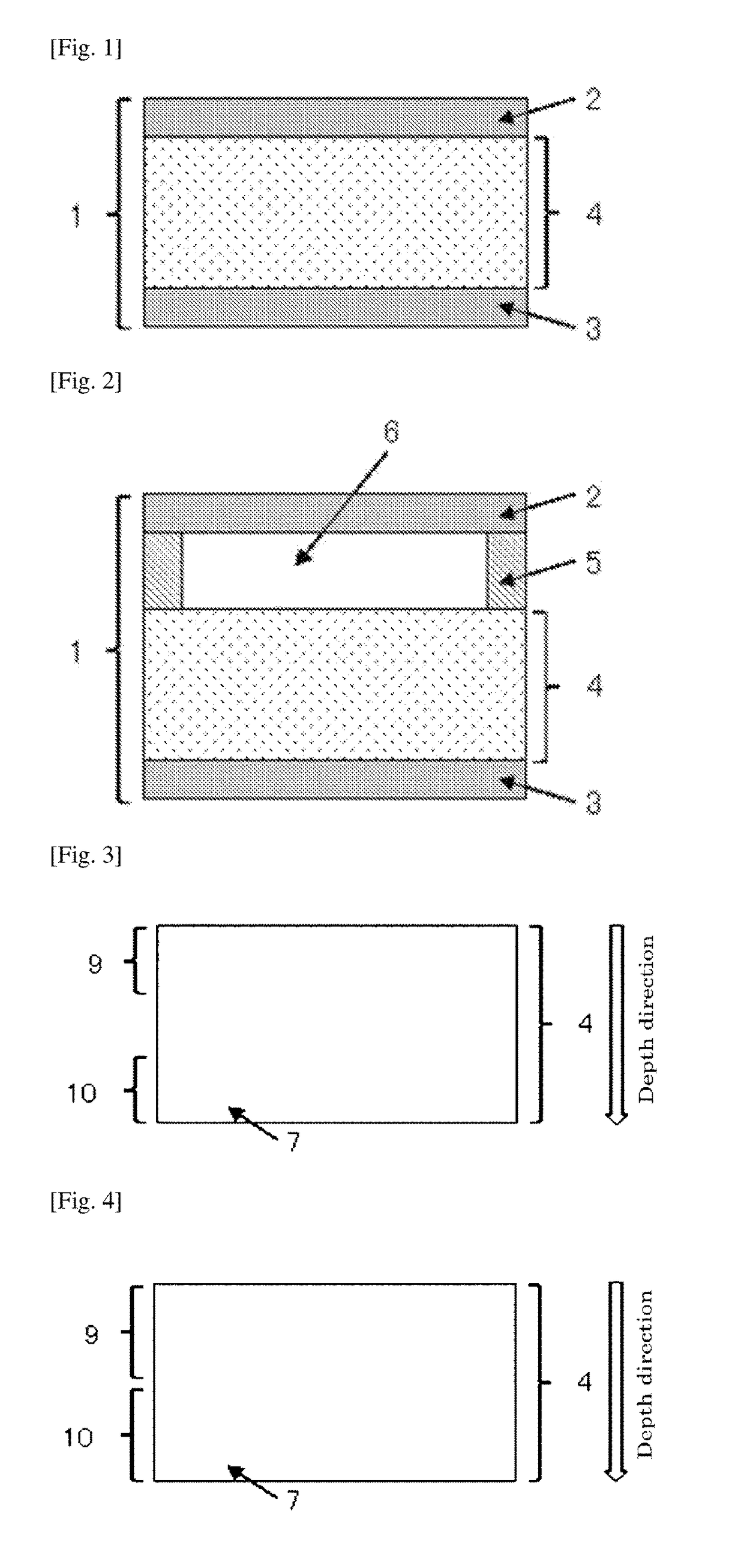

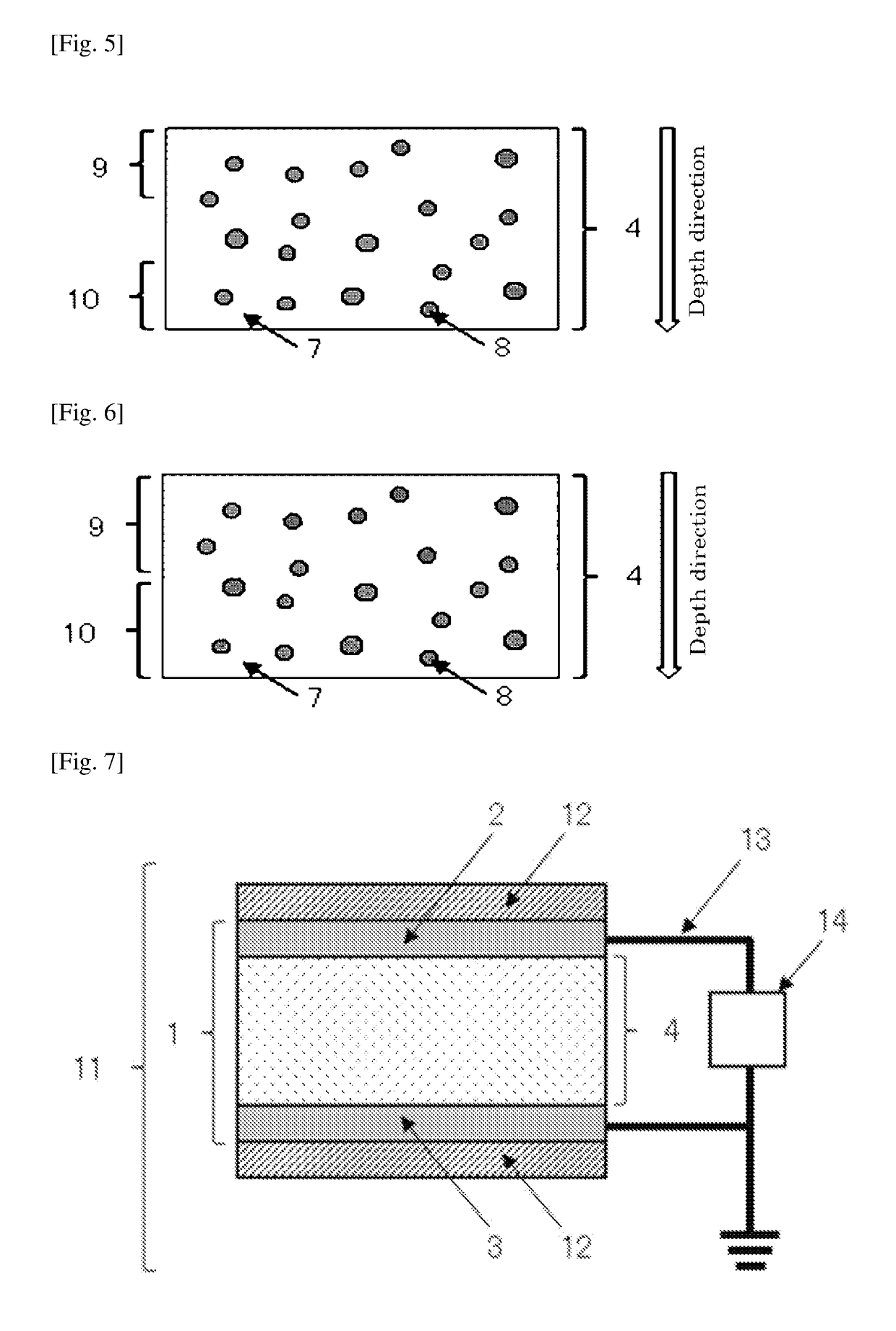

[0206]—Production of Element—

[0207]The obtained intermediate layer was s...

example 2

[0222]

[0223]—Production of Intermediate Layer—

Silicone rubber (KE-1935, manufactured by Shin-Etsu Chemical Co., Ltd.) was applied onto a polyethylene terephthalate (PET) film, and the applied silicone rubber composition was heated to cure at 120° C. for 30 minutes, to thereby form a thin film having a thickness of 100 μm.

Subsequently, the thin film was subjected to a corona discharge treatment in the same manner as in Example 1. Then, the PET film was peeled to thereby produce an intermediate layer of Example 2.

[0224]—Productions of Element and Electric Generator—

[0225]An element and an electric generator of Example 2 were produced using the produced intermediate layer in the same manner as in Example 1.

[0226]

[0227]>

[0228]The produced intermediate layer of Example 2 was subjected to a measurement of an infrared absorption spectrum in the same manner as in Example 1. As a result, the variation rate of the peak intensity ratio was 0.80. It was confirmed from the obtained variation rat...

example 3

[0231]

[0232]—Production of Intermediate Layer—

[0233]A silicone rubber composition was prepared by dispersing 100 parts by mass of silicone rubber (IVS4312, manufactured by Momentive Performance Materials Inc.), 50 parts by mass of barium titanate (208108, manufactured by Sigma-Aldrich Co., LLC.).

[0234]Subsequently, the silicone rubber composition was applied onto a polyethylene terephthalate (PET) film, and the applied silicone rubber composition was heated to cure at 120° C. for 30 minutes, to thereby form a thin film having a thickness of 100 μm.

[0235]Subsequently, the thin film was subjected to a corona discharge treatment in the same manner as in Example 1. Then, the PET film was peeled to thereby produce an intermediate layer of Example 3.

[0236]—Productions of Element and Electric Generator—

[0237]An element and an electric generator of Example 3 were produced using the produced intermediate layer in the same manner as in Example 1.

[0238]

[0239]>

[0240]The produced intermediate la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com