Method for producing porous silicone sheet, frozen body, and porous silicone sheet rolled-body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0069]n-Hexadecyltrimethylammonium chloride (10 g) as a surfactant and urea (50 g) were added to 5 mM acetic acid aqueous solution (150 mL), followed by mixing those in a glass vessel under stirring.

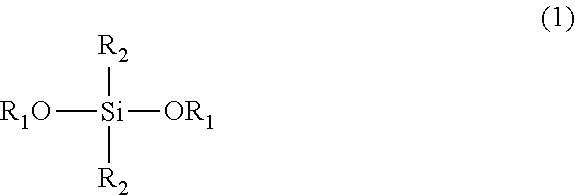

[0070]Methyl trimethoxysilane (30 mL) and dimethyl dimethoxysilane (20 mL) as precursors were added to the glass vessel, followed by stirring with a stirrer for 60 minutes. After stirring, the resulting solution was transferred to a cylindrical closed vessel, and heated at 80° C. for 24 hours, thereby hydrolyzing urea to form basic conditions. The precursors hydrolyzed were polycondensed by a sol-gel reaction under the basic conditions.

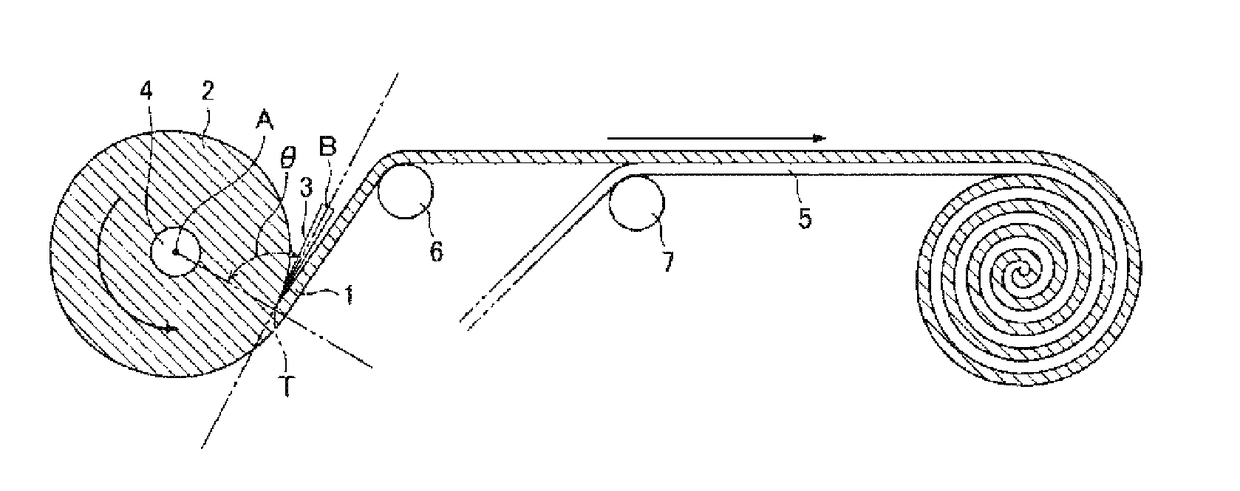

[0071]The wet gel (swallen gel) obtained was allowed to stand in a freezer of −10° C. for 5 hours in the state of placing the wet gel in the vessel, and formed into a frozen state. The cylindrical wet gel in a frozen state was taken out of the vessel, a mandrel was driven into the cylindrical wet gel along a center axis thereof, and the cylindrical wet gel...

example 2

[0072]A porous silicone body formed into a sheet in a roll form (rolled-body of a porous silicone sheet) was obtained under the same conditions as in Example 1, except that cleaning by FV cleaning method (a method in which a chrysanthemum type rotor rotates in punching metal roll to generate water flow in an opening part of the punching metal roll, and an object to be cleaned is brought into contact with the water flow to perform cleaning, number of revolution of chrysanthemum type rotor: 450 rpm, cleaning liquid: water, water temperature: 25° C., path length: 10 m) was conducted as the cleaning step. Similar to Example 1, as a result of measuring an apparent specific density of the porous silicone body prepared, it was a normal numerical value of 0.09 g / cc, and it was confirmed that impurities could be appropriately removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com