A net shape casting mold and method for an aluminum alloy annular fully enclosed lumen structure

A casting mold, fully enclosed technology, applied in the field of light alloy casting, can solve the problems of difficult cleaning, insufficient wall thickness, low dimensional accuracy, etc., achieve high dimensional accuracy and organizational performance, avoid application problems, and simple gating system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

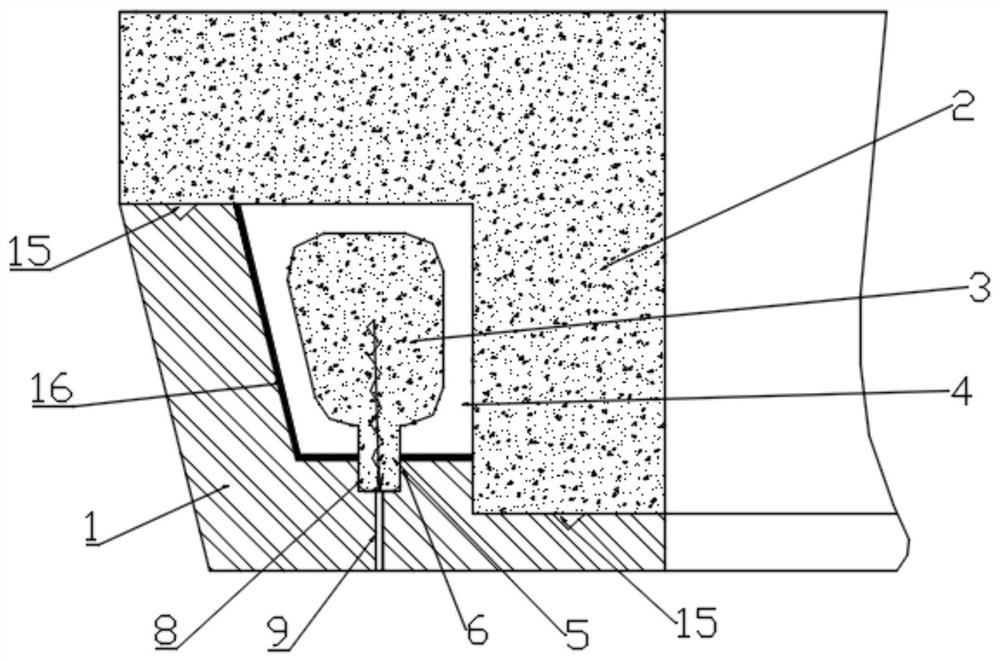

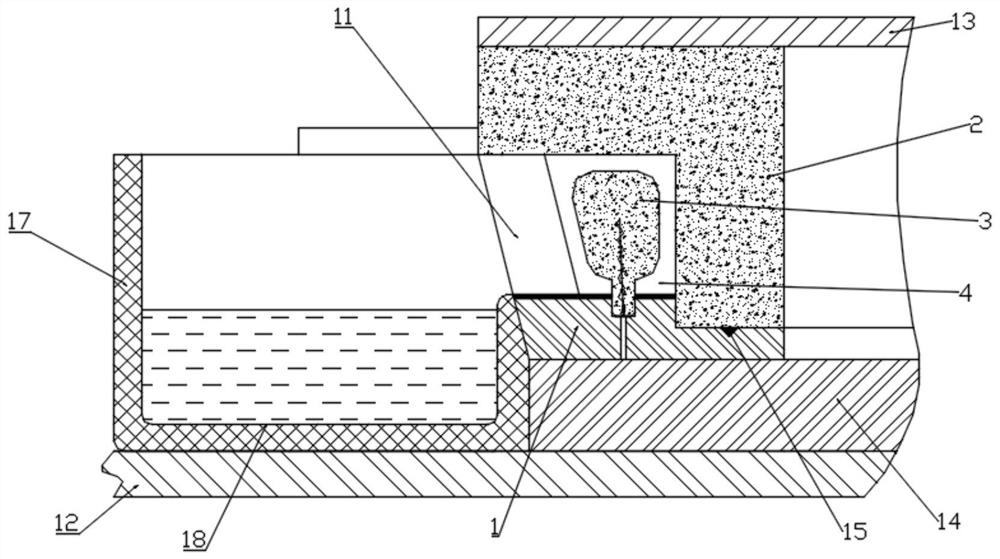

[0034] Example: such as Figure 1-6 As shown, this embodiment provides a net-shape casting mold with an aluminum alloy annular fully-enclosed lumen structure, which includes an annular outer mold 1 and an inner mold 2, and the outer mold and inner mold are fastened to form an annular cavity. An annular core mold 3 is arranged in the annular cavity, and the annular core mold forms a cavity 4 together with the inner mold and the outer mold. Wherein, both the outer mold and the inner mold are annular, the outer mold includes a bottom wall and an annular outer wall, and the inner mold includes a top wall and an annular inner wall.

[0035] In this embodiment, the outer mold is composed of two halves of the cast iron outer mold split in half, and a gate 11 is provided on one side of the parting surface of the cast iron outer mold.

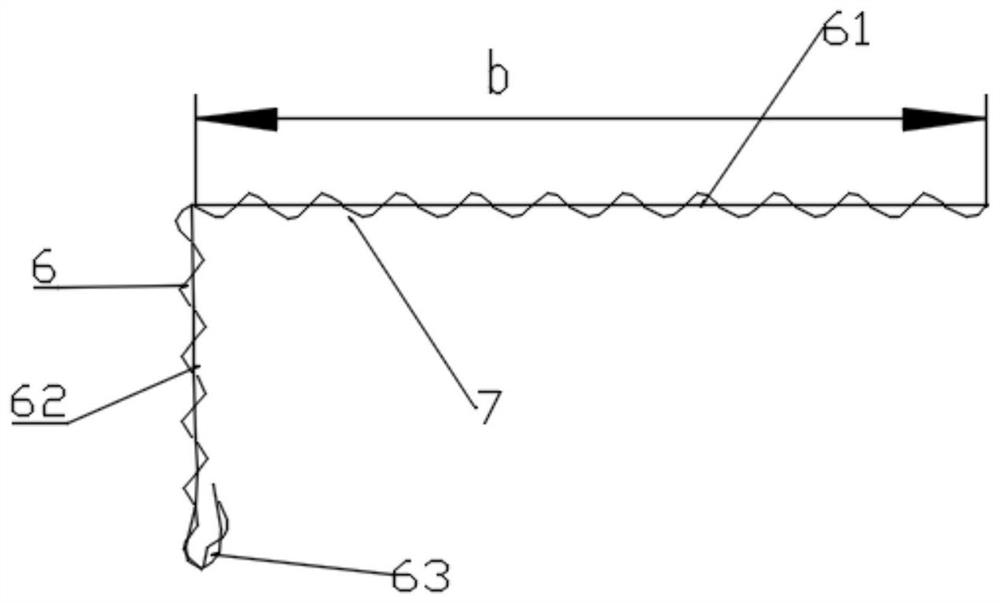

[0036] The lower part of the core mold 3 is provided with a column 5 inserted into the outer mold, and an L-shaped mandrel 6 corresponding to the colu...

example 1

[0044] Example 1: It is necessary to manufacture a ZL205A aluminum alloy annular lumen casting, with an outer diameter of Φ850mm, an inner diameter of Φ620mm, and a height of 180mm. The lumen section structure is body-shaped. Follow the steps below:

[0045] Step 1: Prepare two halves of the gray iron 250 outer mold by sand casting method. After machining, the surface of the cavity is shot blasted with 40-80 meshes, and the surface of the cavity is covered with sand to form the sand layer of the outer mold. 16. A gate is arranged on one side of the parting surface of the cast iron outer mold. The specific sand covering method is: evenly brush (0.3-0.5) mm thick tung oil on the corresponding area of the cavity surface, spray a layer of 280-320 mesh sand on the surface, and bake at 220 ° C for 60 minutes until the surface is brown or light green. , Clean the loose sand on the surface with compressed air after it comes out of the furnace, and repair it with 200-grit sandpaper...

example 2

[0053] Example 2: It is necessary to manufacture a ZL101 aluminum alloy circular section lumen casting, with an outer diameter of Φ420mm, a section outer diameter of Φ80mm, and a tube wall thickness of 12mm. Follow the steps below:

[0054] Step 1: Prepare two halves of the gray iron 250 outer mold by sand casting method. After machining, the surface of the cavity is shot blasted with 40-80 mesh, and the surface of the cavity is covered with sand. A gate is arranged on one side of the parting surface of the cast iron outer mold. The specific sand covering method is: evenly brush (0.3-0.5) mm thick tung oil on the corresponding area of the cavity surface, spray a layer of 280-320 mesh sand on the surface, and bake at 220 ° C for 30 minutes until the surface is brown or light green. , Clean the loose sand on the surface with compressed air after it comes out of the furnace, and repair it with 200-grit sandpaper;

[0055] Step 2: The hollow inner cavity of the closed tube is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com