Concrete mix designs using a plurality of reinforcement fibers systems

a reinforcement fiber and mix technology, applied in the field of concrete formulations, can solve the problems of reducing the scope of application and placement properties, reducing the degree of mechanical resistance that can be achieved, both in terms of compressive strength, flexural strength or ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0145]

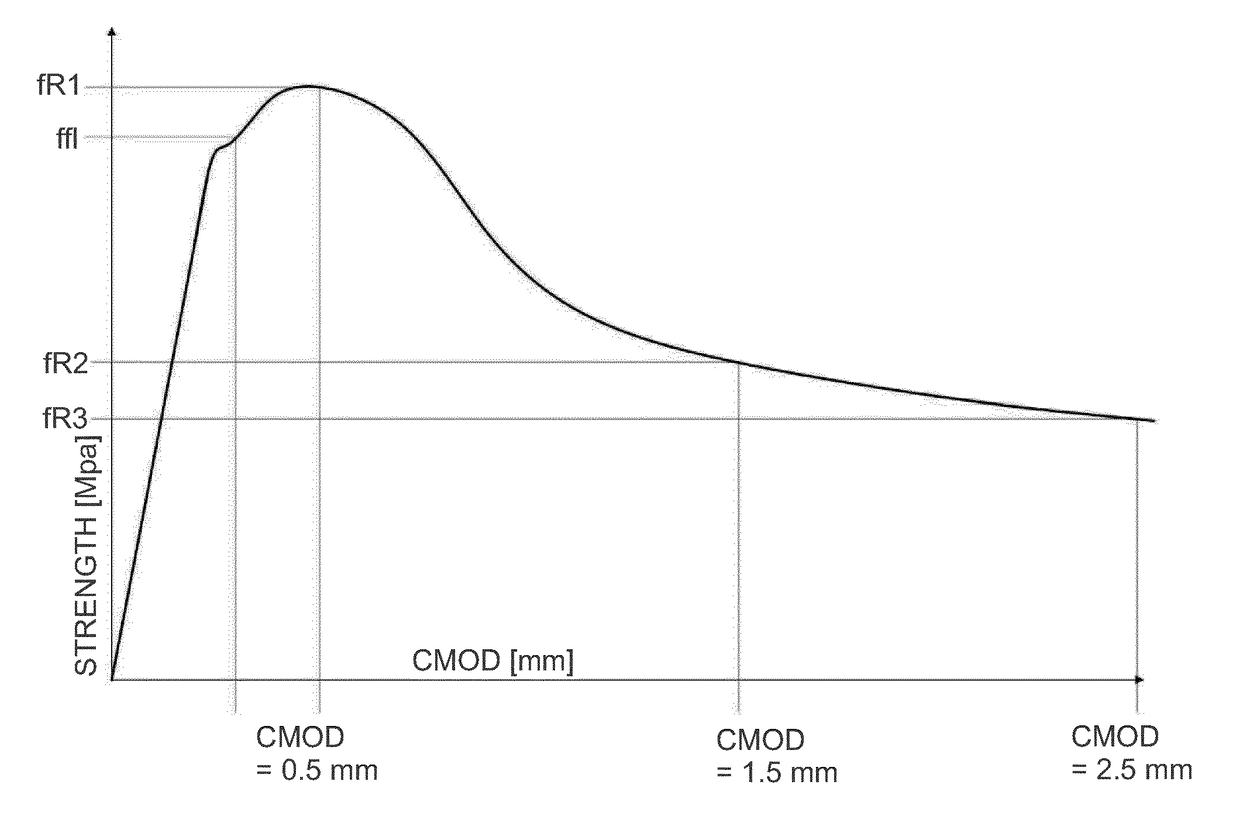

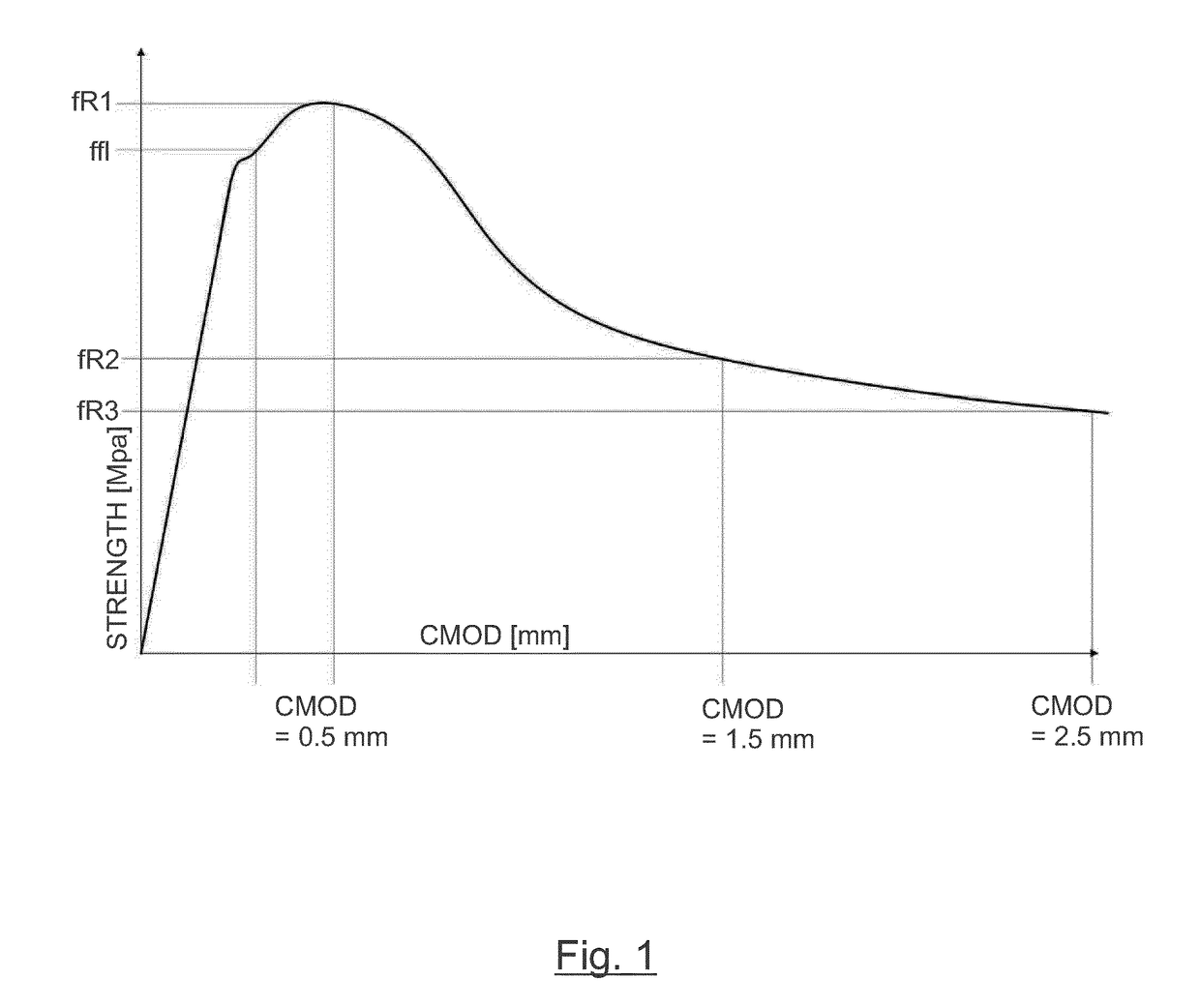

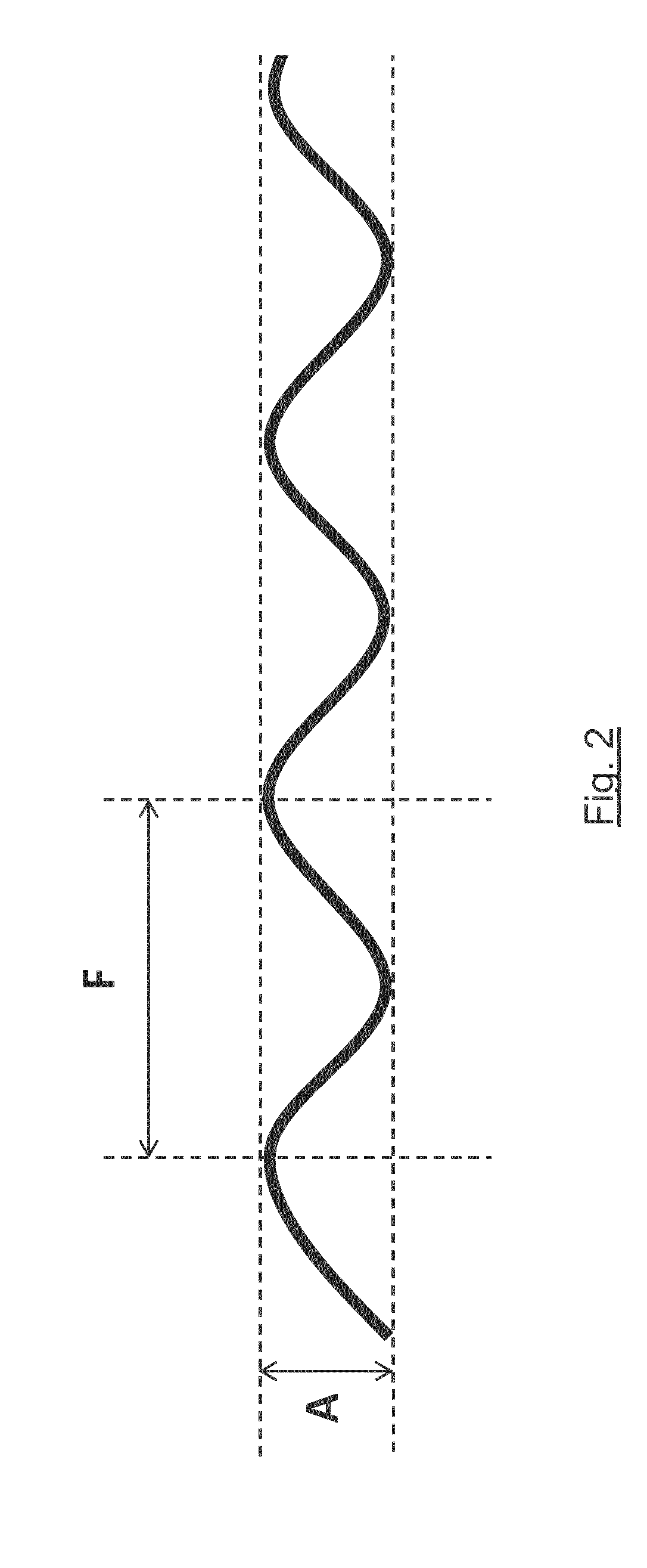

MaterialUnitQuantityTotal binder contentkg / m3410CEM I 52.5 Nkg / m3410w / b eff—0.43Admix System I% total binder1.40%contentAdmix System II% total binder0.50%contentSand 0 / 4 roundkg / m3707Gravel 4 / 8 crushedkg / m3443Gravel 8 / 11 crushedkg / m3621Fiber type A1 - l / d = 80-l = 60 mm, YS =% volume0.50%2400, US = 2890 MPa, hookedFiber type A2 - l / d eq. = 50-l = 38 mm,% volume0.25%YS = 800 MPa, US = 870 MPa, Wavyshape, A = 3 mm, F = 2 cm−1Entrained airl / m315Paste volumel / m3321.46Slump class—SF1Slumpmm670Workability retentionmin90fcMPa40fflMPa5.1fr1MPa4.7fr3MPa5.2E modulusGpa31.8

[0146]Example 1 shows a concrete mix design with medium compressive strength and low paste volume according to the invention, with fibers systems A1 and A2, as well as admixture systems I and II.

example 2

[0147]

MaterialUnitQuantityTotal binder contentkg / m3750CEM II / A-LL 52.5 Nkg / m3500Fly ashkg / m3200Silica fumekg / m350w / b eff—0.32Admix System I% total binder2.70%contentAdmix System II% total binder0.30%contentAdmix System III% total binder6.20%contentSand 0 / 4 crushedkg / m3646Gravel 4 / 8 roundkg / m3453Gravel 8 / 10 roundkg / m3194Fiber type A1 - l / d = 80-l = 60 mm, YS =% volume0.75%2400, US = 2890 MPa, hookedFiber type A2 - l / d eq. == 50, l = 38 mm,% volume0.30%YS = 800 MPa, US = 870 MPa, Wavyshape, A = 2.5 mm, F = 4.5 cm−1Entrained airl / m326Paste volumel / m3530.79Slump class—SF2Slumpmm740Workability retentionmin120fcMPa74fflMPa8.5fr1MPa11.8fr3MPa14.7E modulusGpa41.9

[0148]Example 2 shows a concrete mix design according to the invention with high compressive strength and high paste volume, with fibers systems A1 and A2, as well as admixture systems I and II and III.

example 3

[0149]

MaterialUnitQuantityTotal binder contentkg / m3630CEM III / B 52.5Rkg / m3400Fly ashkg / m380Silica fumekg / m350w / b eff—0.35Admix System I% total binder1.80%contentAdmix System II% total binder0.45%contentSand 0 / 4 roundkg / m3721Gravel 4 / 8 Crushedkg / m3289Gravel 8 / 11 crushedkg / m3434Fiber type A1 - l / d = 40-l =% volume0.75%100 mm, YS = 1850MPa, US = 1920 MPa, straightEntrained airl / m338Paste volumel / m3441.54Slump class—S5Slumpmm240Workability retentionmin105fcMPa65fflMPa6.7fr1MPa2.1fr3MPa2.5E modulusGpa37.5

[0150]Example 3 shows a concrete mix design with high compressive strength medium to high paste and high binder content, using fibers system A1 only (without fiber system A2 or fiber system B). The concrete mix design of example 3 is not according to the invention since it does not contain fibers system B and does meet the requirements related to the ductility values to be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com