Method for Obtaining a Cooking Vessel Having a Colored, Hard, Anodized Outer Surface

a cooking vessel and hard technology, applied in the direction of liquid/solution decomposition chemical coating, application, electric/magnetic/electromagnetic heating, etc., can solve the problem of not being as easy to clean the surface thus obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

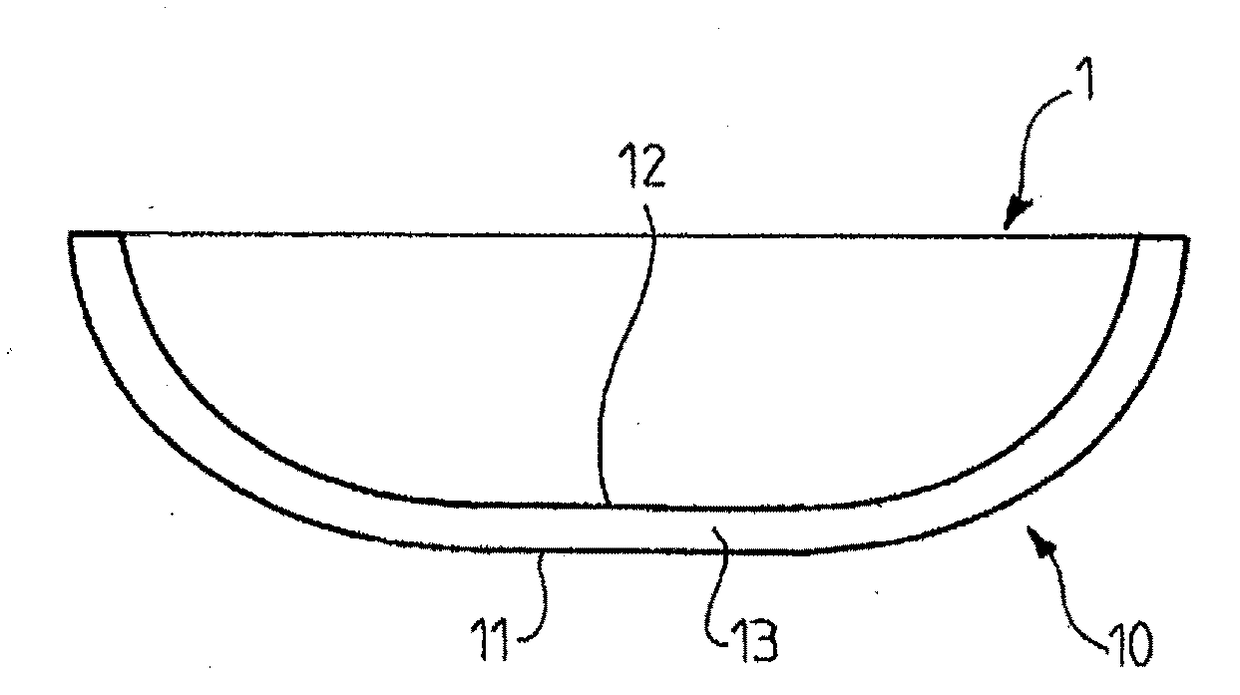

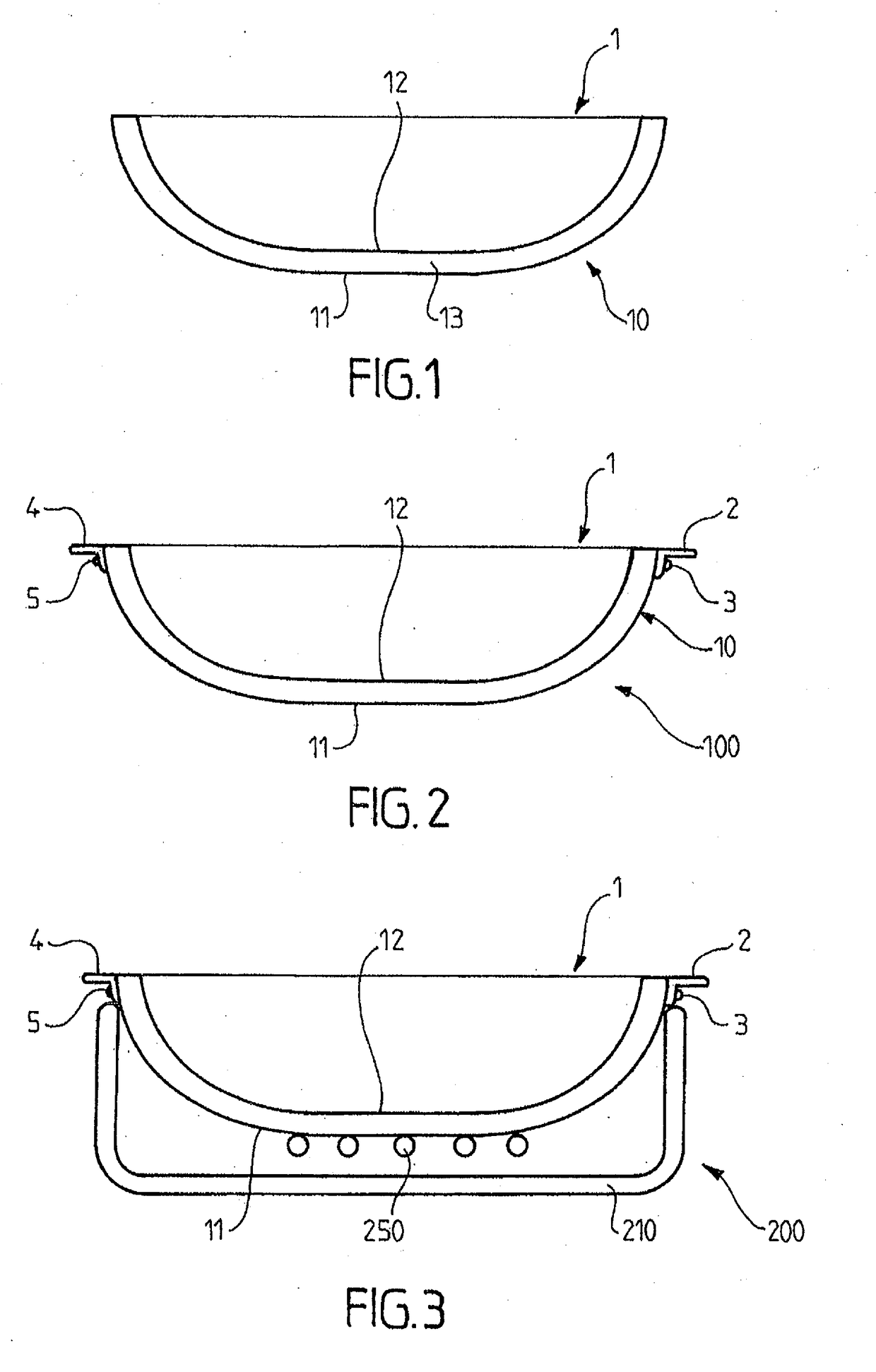

[0065]PTFE coating of the inner surface 12, hard anodization of the outer surface 11, coloring of the hard anodized outer surface 11, transparent sol-gel for coating the colored, hard anodized outer surface 11.

example 2

[0066]PTFE coating of the inner surface 12, hard anodization of the outer surface 11, colored sol-gel for coating the hard anodized outer surface 11.

example 3

[0067]PTFE coating of the inner surface 12, hard anodization of the outer surface 11, coloring of the hard anodized outer surface 11, colored sol-gel for coating the colored, hard anodized outer surface 11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com