Cold Cranking Simulator Viscosity Reducing Base Stocks and Lubricating Oil Formulations Containing the Same

a cranking simulator and viscosity reduction technology, which is applied in the field of cold cranking simulator viscosity, can solve the problems of difficult to achieve the maximum allowable kv100 in engine oil, negatively affecting wear protection in automotive engines, and affecting wear performance, so as to reduce the ccsv of an oil composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

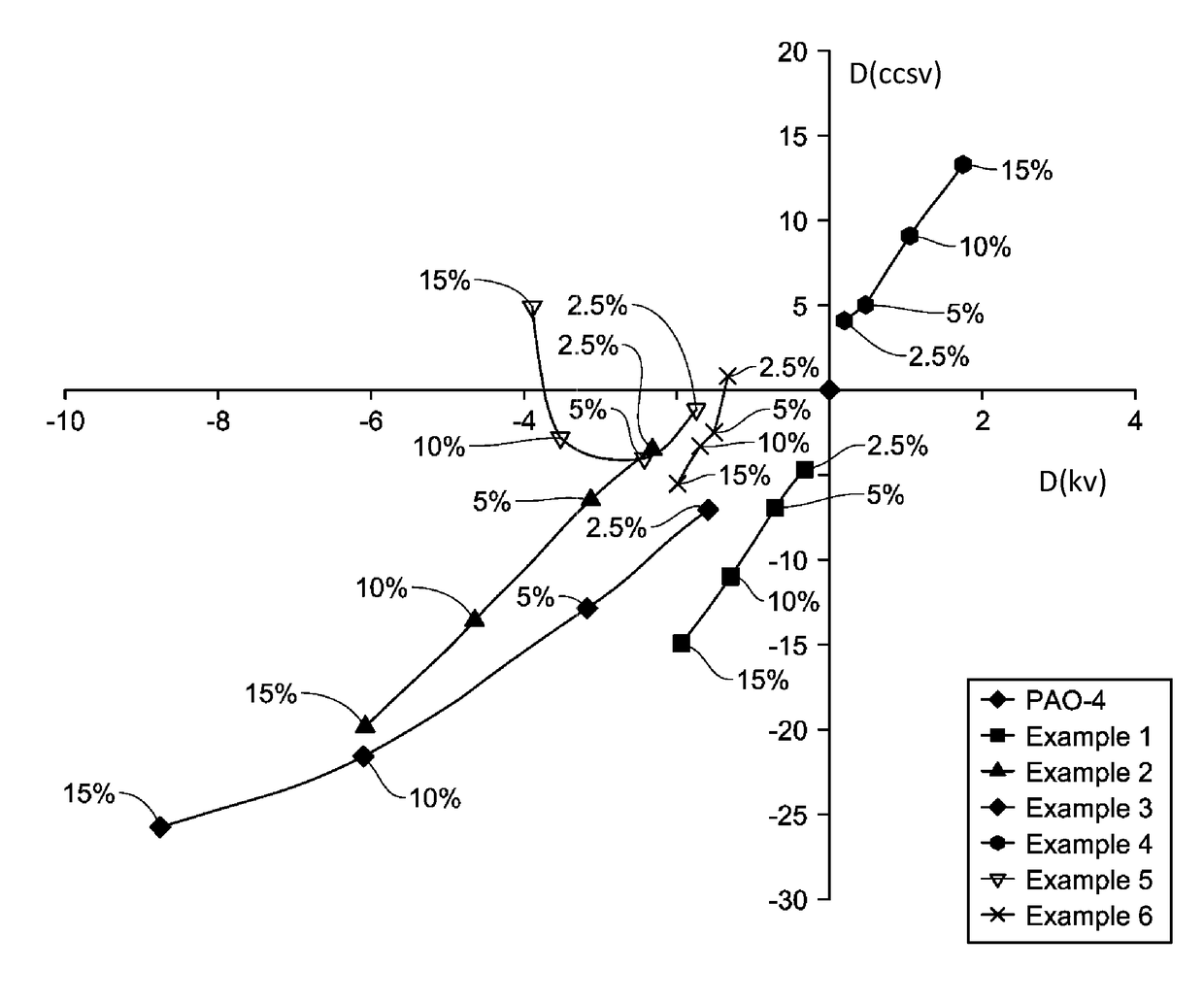

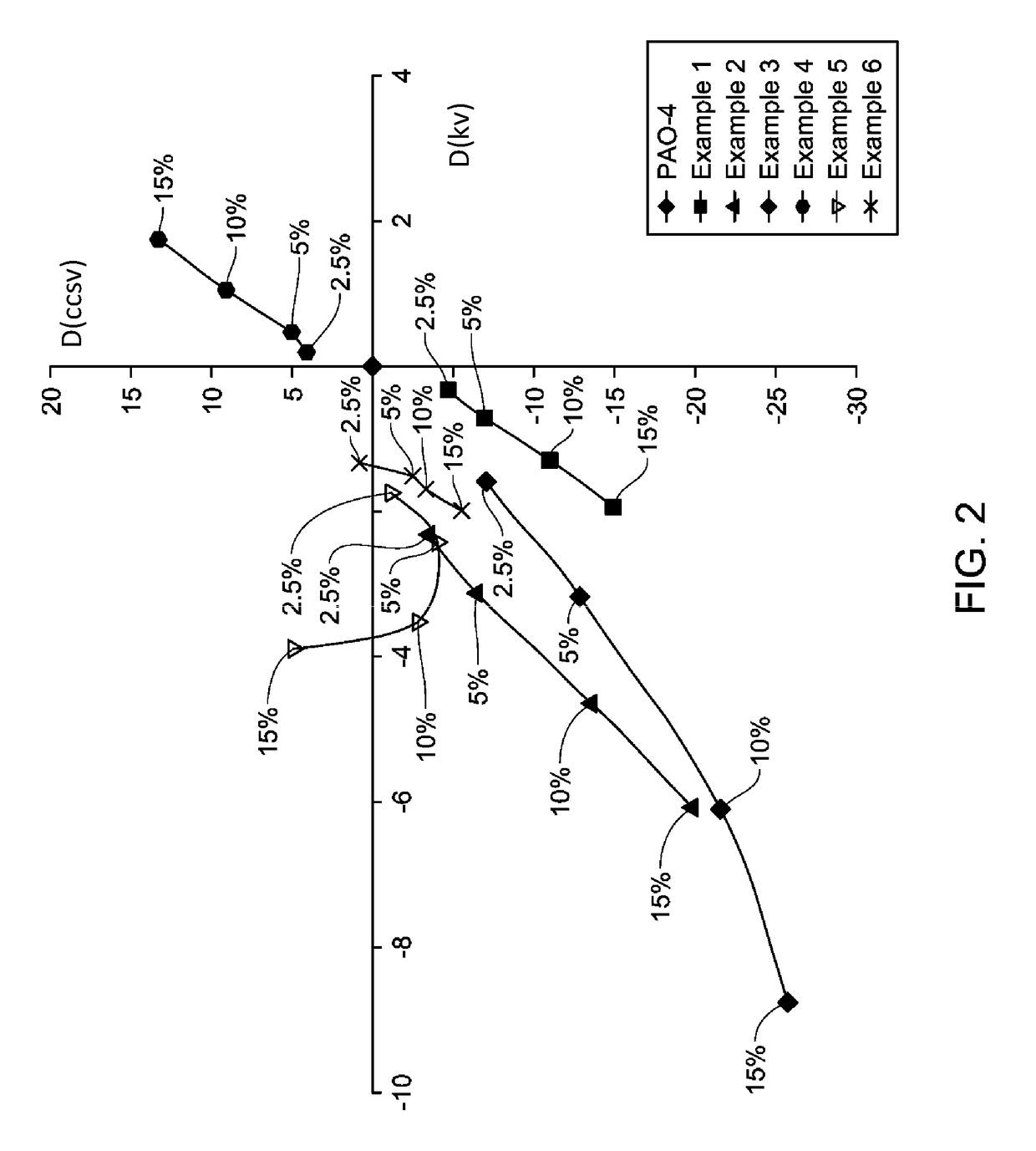

[0102]2-Octyldodecyl dodecanoate derived from a Guerbet alcohol (i.e., 2-octyl-1-dodecanol) and a linear acid (i.e., decanoic acid, a linear C12 carboxylic acid) demonstrated excellent CCSV-reducing efficacy when blended at low treat rate with PAO-4 as the reference oil. As shown in FIG. 2, 2-octyldodecyl dodecanoate demonstrated a negative D(ccsv)3 is quite high, making it a highly effective CCSV-reducing base stock without significantly impacting the KV100 of the mixture oil.

example 2

[0103]2-Octyldodecyl nonanoate derived from a Guerbet alcohol (i.e., 2-octyl-1-dodecanol) and a linear acid (i.e., nonanoic acid, a linear C9 carboxylic acid) demonstrated excellent CCSV-reducing efficacy when blended at low treat rate with PAO-4 as the reference oil. As shown in FIG. 2, 2-octyldodecyl nonanoate demonstrated a negative D(ccsv)3 is quite high, making it a highly effective CCSV-reducing base stock without significantly impacting the KV100 of the mixture oil.

example 3

Comparative

[0104]Di-iso-octyl adipate derived from iso-octyl alcohol and adipic acid (Esterex™ A32, a commercial Group V ester-type base stock available from ExxonMobil Chemical Company having an address at 4500 Bayway Drive, Baytown, Tex. 77450, United States) demonstrated CCSV-reducing efficacy as shown in FIG. 3. However, the high Noack volatility (>30%) of this di-ester precludes this ester from being an inventive example of a CCSV-reducing base stock. As shown by this example, it is possible to reduce the CCSV of a formulation simply by including an ester of low molecular weight such as Esterex™ A32. However, the high NV value of such an ester renders it unsuitable for an engine oil formulation. On the contrary, the CCSV-reducing mono-esters of this disclosure have a NV value of no higher than 20%, preferably no higher than15%, still more preferably no higher than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com