Generalized frequency conversion system for steam turbine generator unit

a technology of general frequency conversion and steam turbine generator, which is applied in the direction of electric generator control, machines/engines, mechanical equipment, etc., can solve the problems of large number of rotating auxiliary machines such as pumps and fans provided in power plants that need to consume a large amount of electricity, serious waste of electricity, and sharp drop in working efficiency, so as to achieve high efficiency, low cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

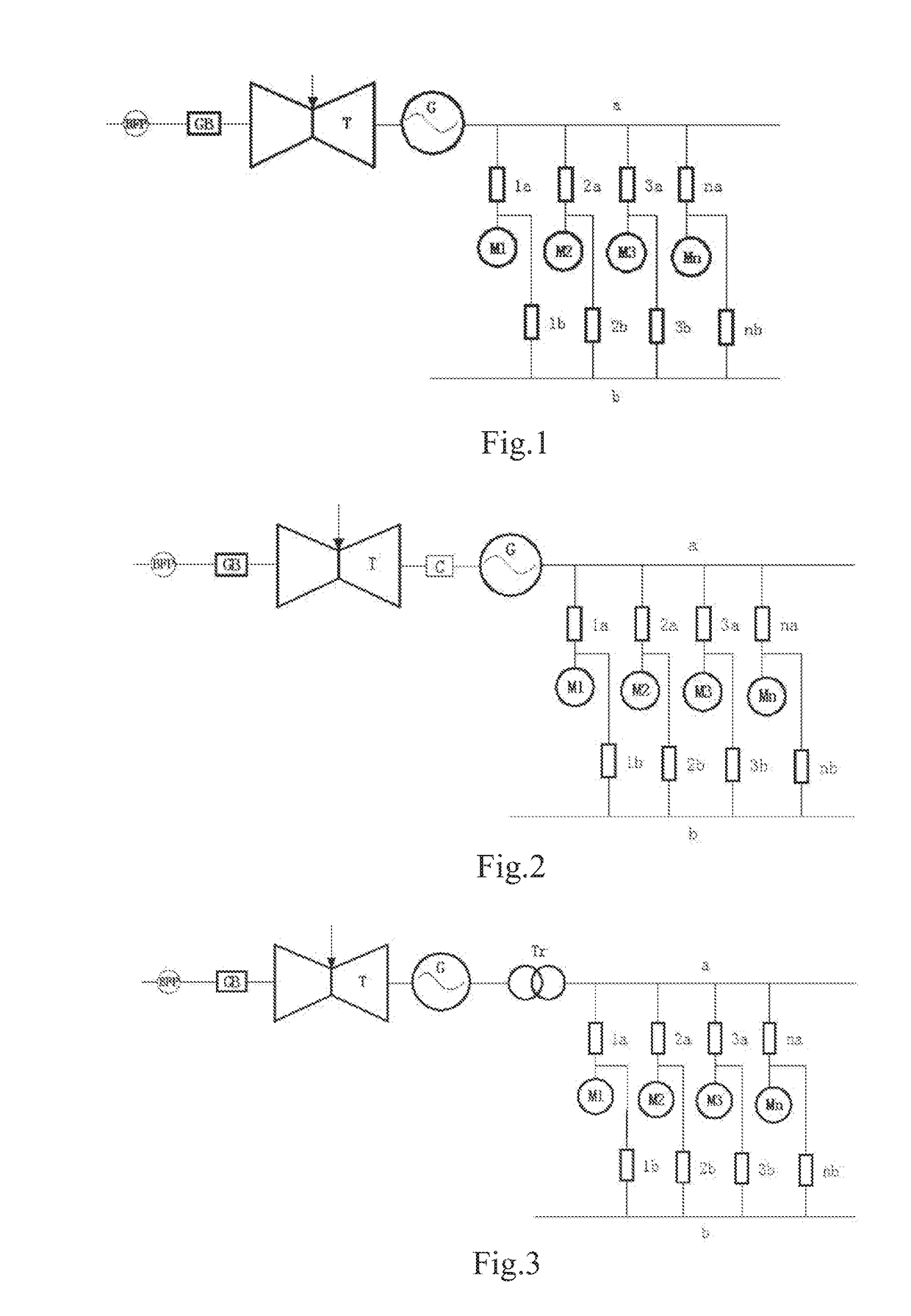

embodiment 1

[0039]As illustrated in FIG. 1, it illustrates a specific embodiment of a generalized frequency conversion system for a steam turbine generator unit, comprising a steam turbine T, a water feeding pump BFP, a generator G, a speed increasing gearbox GB, a variable frequency bus a and an industrial frequency bus b. Auxiliary machines M1, M2, M3, . . . , Mn are connected with the variable frequency bus a through switches 1a, 2a, 3a, . . . , na, and are connected with the industrial frequency bus b through switches 1b, 2b, 3b, . . . , nb. With a change in load of the unit, parameters of steam entering the steam turbine and an extracted steam amount are adjusted (changed) accordingly, so that the rotating speed of the steam turbine changes accordingly. In this way, on the one hand, the rotating speed of the water feeding pump is changed indirectly through the gearbox; and on the other hand, the frequency of alternating current outputted by the generator is changed directly. The generator ...

embodiment 2

[0041]As illustrated in FIG. 2, it illustrates another specific embodiment of a generalized frequency conversion system for a steam turbine generator unit, comprising a steam turbine T, a water feeding pump BFP, a generator G, a speed increasing gearbox GB, a clutch system C, a variable frequency bus a and an industrial frequency bus b. Auxiliary machines M1, M2, M3, . . . , Mn are connected with the variable frequency bus a through switches 1a, 2a, 3a, . . . , na and are connected with the industrial frequency bus b through switches 1b, 2b, 3b, . . . , nb. With a change in load of the unit, the parameters of steam entering the steam turbine and the extracted steam amount are adjusted (changed) accordingly, so that the rotating speed of the steam turbine changes accordingly. In this way, on the one hand, the rotating speed of the water feeding pump is changed indirectly through the gearbox; and on the other hand, the frequency of alternating current outputted by the generator is cha...

embodiment 3

[0043]As illustrated in FIG. 3, it illustrates another specific embodiment of a generalized frequency conversion system for a steam turbine generator unit, comprising a steam turbine T, a water feeding pump BFP, a generator G, a speed increasing gearbox GB, a double-winding voltage transformer Tr, a variable frequency bus a and an industrial frequency bus b. Auxiliary machines M1, M2, M3, . . . , Mn are connected with the variable frequency bus a through switches 1a, 2a, 3a, . . . , na and are connected with the industrial frequency bus b through switches 1b, 2b, 3b, . . . , nb. With a change in load of the unit, the parameters of steam entering the steam turbine and the extracted steam amount are adjusted (changed) accordingly, so that the rotating speed of the steam turbine changes accordingly. In this way, on the one hand, the rotating speed of the water feeding pump is changed indirectly through the gearbox; and on the other hand, the frequency of alternating current outputted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com