Ultraviolet curable silicone composition and cured product of same

a silicone composition and ultraviolet technology, applied in the field of ultraviolet curable silicone composition, can solve the problems of inability to eject inkjet, never been a silicone material capable of ejecting inkjet, etc., and achieve the effects of favorable viscosity, surface tension and curability, and favorable rubber properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example

[0056]The present invention is described in detail hereunder with reference to working and comparative examples. However, the invention is not limited to the following working examples.

[0057]Compositions in working examples 1 to 6; and comparative examples 1 and 2 were prepared at the composition ratios shown in Table 1, and then evaluated by the following methods.

[0058]In the following examples, a viscosity of the composition refers to a value measured by a rotary viscometer at 23° C. A surface tension refers to a value measured by a CBVP-Z type automatic surface tensiometer manufactured by Kyowa Interface Science Co., Ltd.

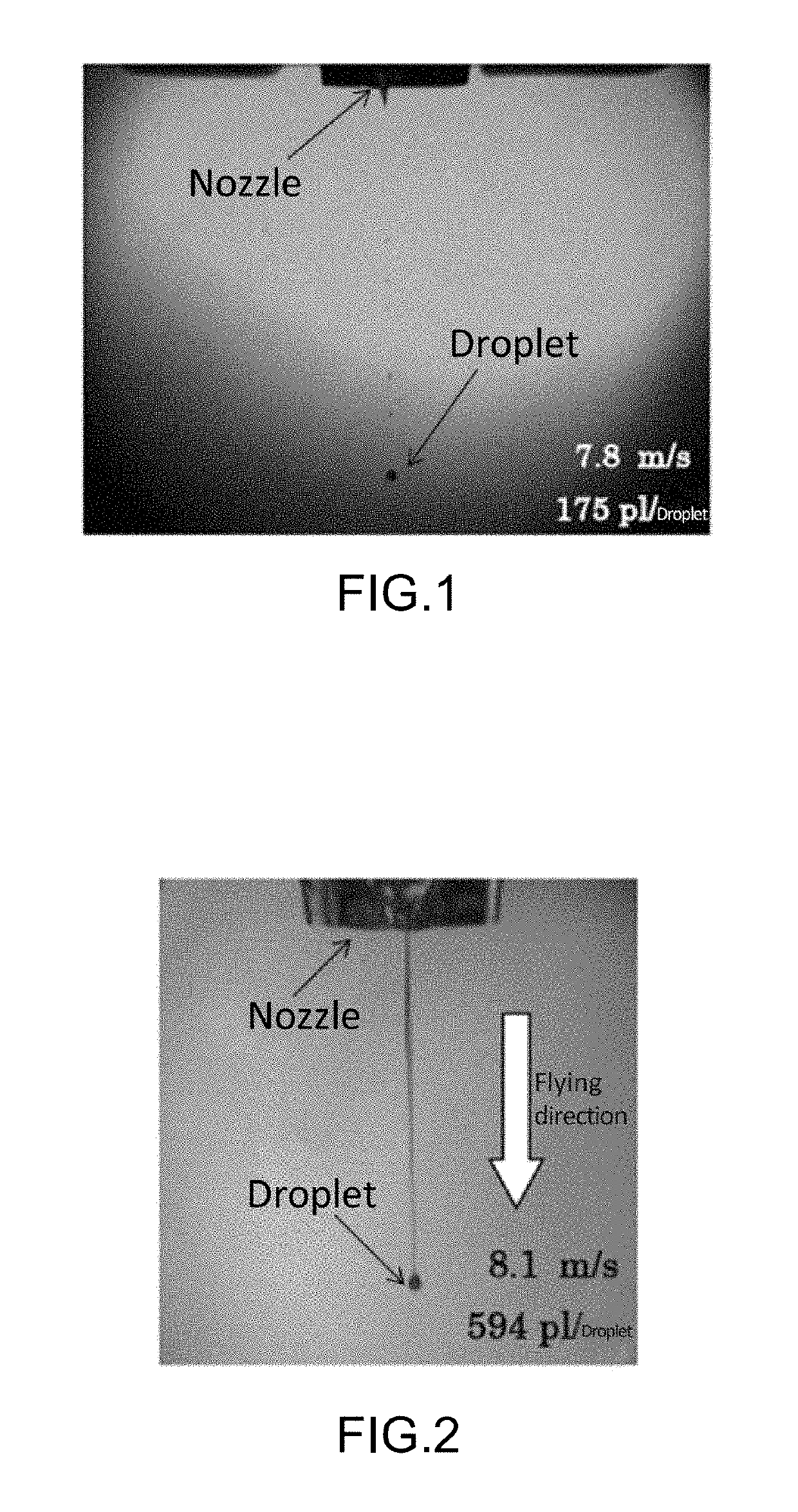

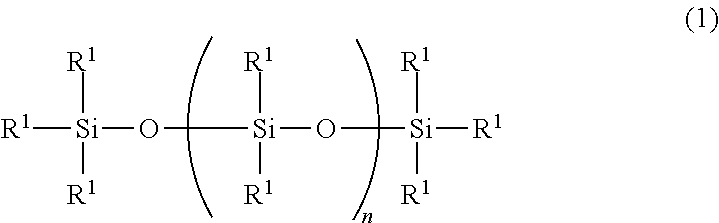

[0059]Further, an inkjet ejection property was evaluated as follows. Specifically, there was used a droplet observation device IJK-2005 (glass-made 1-nozzle inkjet head IJHE-1000) manufactured by MICROJET Corporation, and an ejection status was shot with camera for evaluation under ejection conditions of: drive voltage 80V; head temperature 80° C.; and nozzle dia...

synthesis example 1

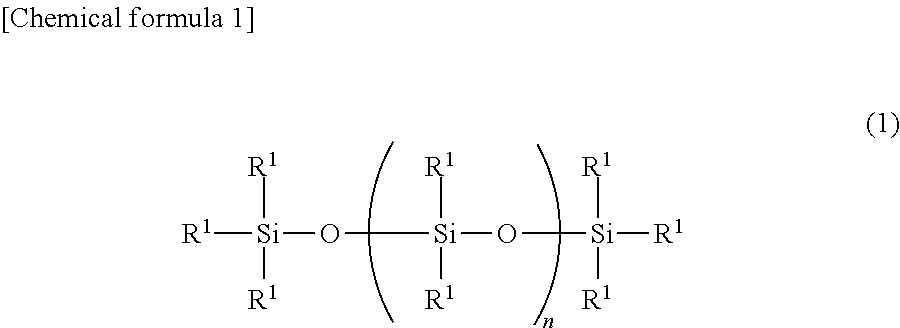

[0063]Put into a glass-made reactor equipped with a thermometer and a stirrer were 42 g of 1,3-bis(methacryloxypropyl)tetramethyldisiloxane, 806 g of octamethylcyclotetrasiloxane and 1.3 g of trifluoromethanesulfonic acid, followed by reacting them at 60° C. for five hours. Later, the temperature was reduced to 25° C., and 4 g of hydrotalcite (KYOWAAD 500 by Kyowa Chemical Industry Co., Ltd.) was added to perform neutralization. After filtration was completed, vacuum concentration was carried out at 120° C. to obtain 700 g of an organopolysiloxane A-1. The structure of A-1 (number of repeating units of dimethylsiloxy groups) was calculated via 29Si-NMR.

synthesis example 2

[0064]Put into a glass-made reactor equipped with a thermometer and a stirrer were 22 g of 1,3-bis(methacryloxypropyl)tetramethyldisiloxane, 248 g of octamethylcyclotetrasiloxane and 0.2 g of trifluoromethanesulfonic acid, followed by reacting them at 60° C. for five hours. Later, the temperature was reduced to 25° C., and 4 g of hydrotalcite (KYOWAAD 500 by Kyowa Chemical Industry Co., Ltd.) was added to perform neutralization. After filtration was completed, vacuum concentration was carried out at 120° C. to obtain 200 g of an organopolysiloxane A-2. The structure of A-2 (number of repeating units of dimethylsiloxy groups) was calculated via 29Si-NMR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com