Light absorbing body-containing film and backlight unit

a technology of backlight unit and film, which is applied in the direction of static indicating device, lighting and heating apparatus, instruments, etc., can solve the problems of poor productivity, poor luminance, and dark peripheral edge portion, and suppress in-plane luminance and chromaticity unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0455]

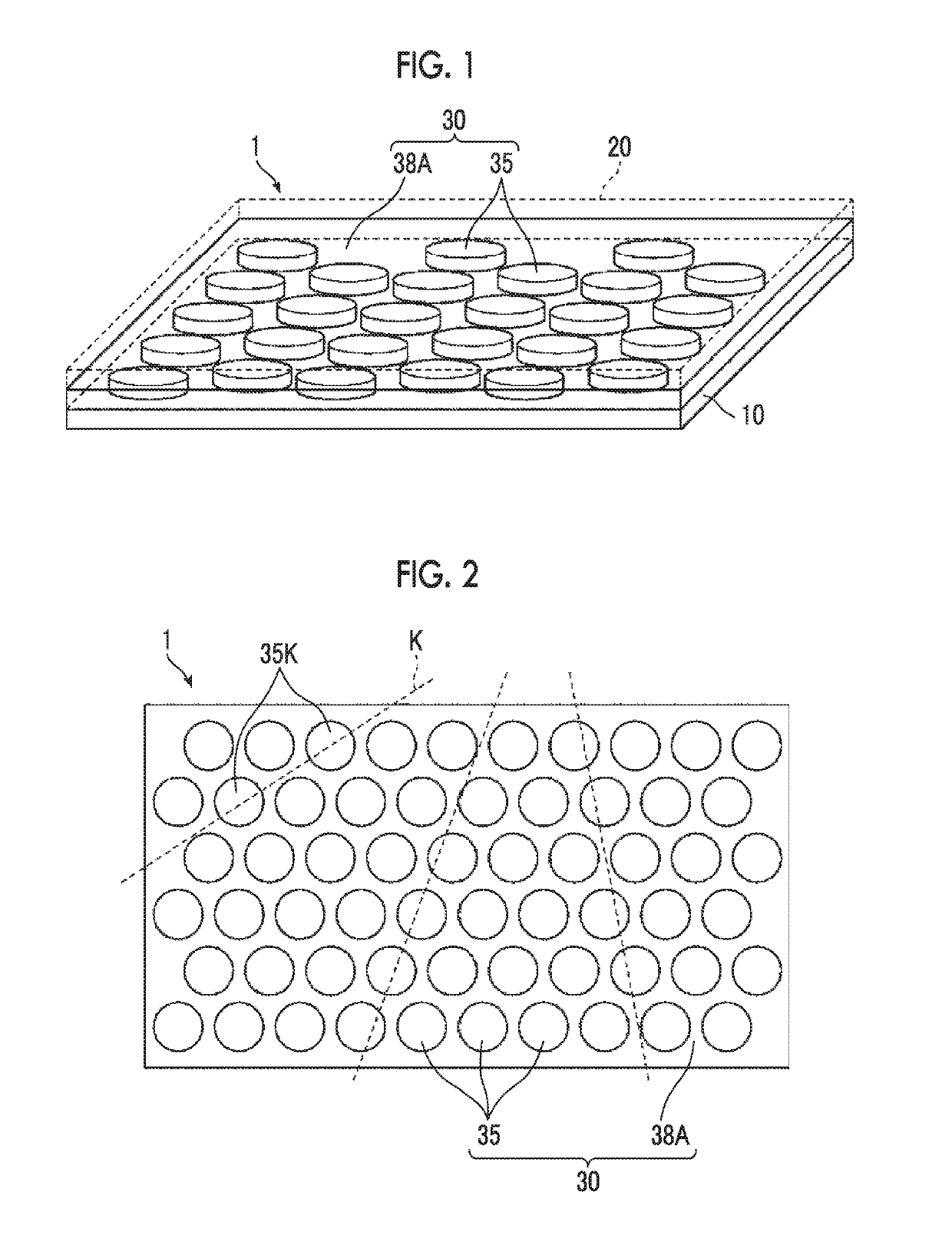

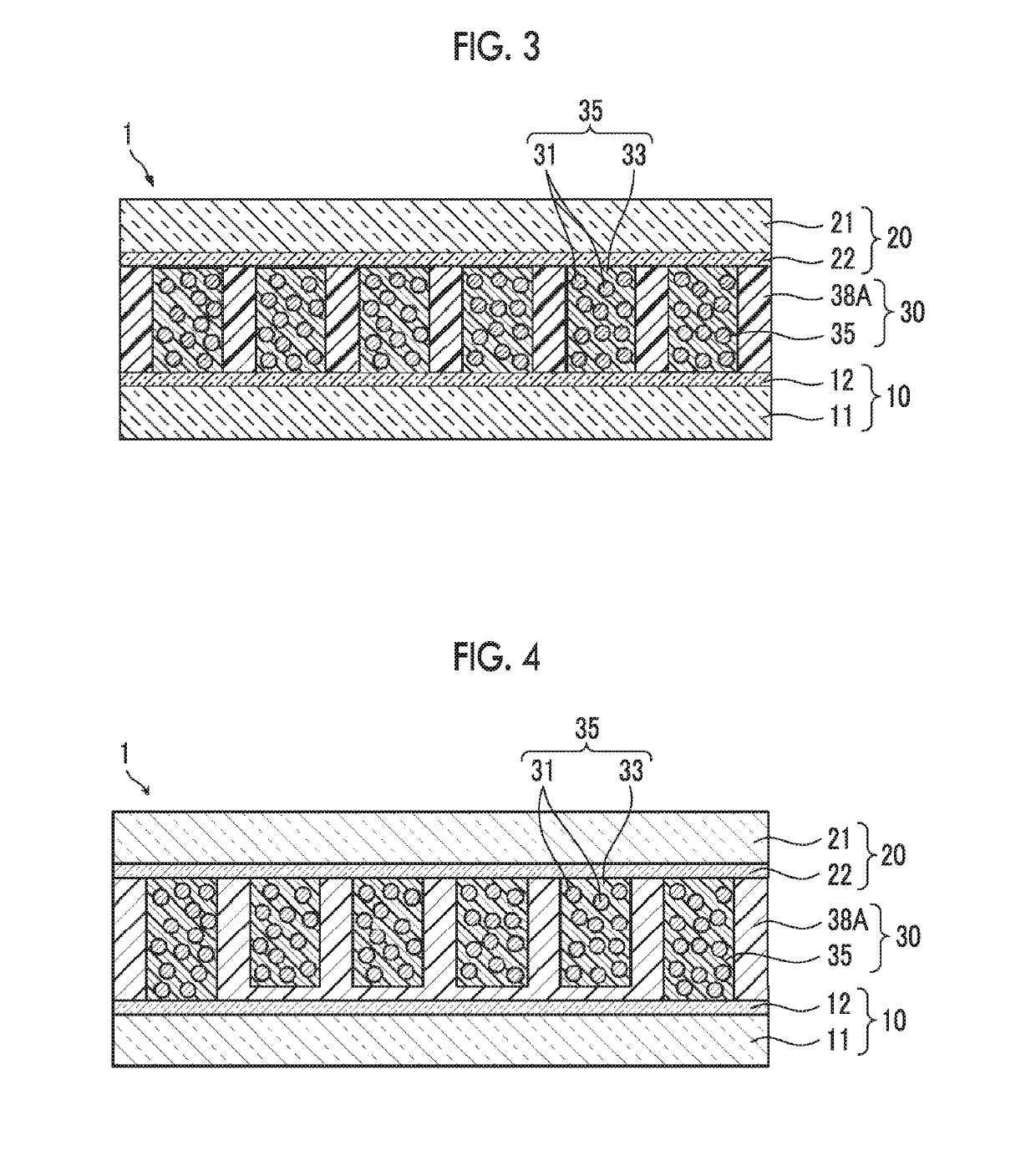

[0456]As a light absorbing material-containing film of the first aspect, a light absorbing material-containing film having a light absorbing material-containing layer was prepared using a coating liquid containing quantum dots as light absorbing bodies,

[0457](Preparation of Barrier Film)

[0458]As a first substrate film and a second substrate film, a barrier film in which a barrier layer made of an inorganic layer was formed on a support film made of PET, and an organic layer coated with the following composition was formed on the barrier layer was prepared as follows.

[0459]Using a PET film (manufactured by Toyoho Co., Ltd., trade name “COSMOSHINE (registered trademark) A4300”, thickness: 23 μm) as a support, an organic layer and an inorganic layer were sequentially formed on one side of the support by the following procedure.

[0460]—Formation of Organic Layer—

[0461]Trimethylolpropane triacrylate (product name “TMPTA”, manufactured by Daicel-Allnex Ltd.) and a photopolymerization...

example 2

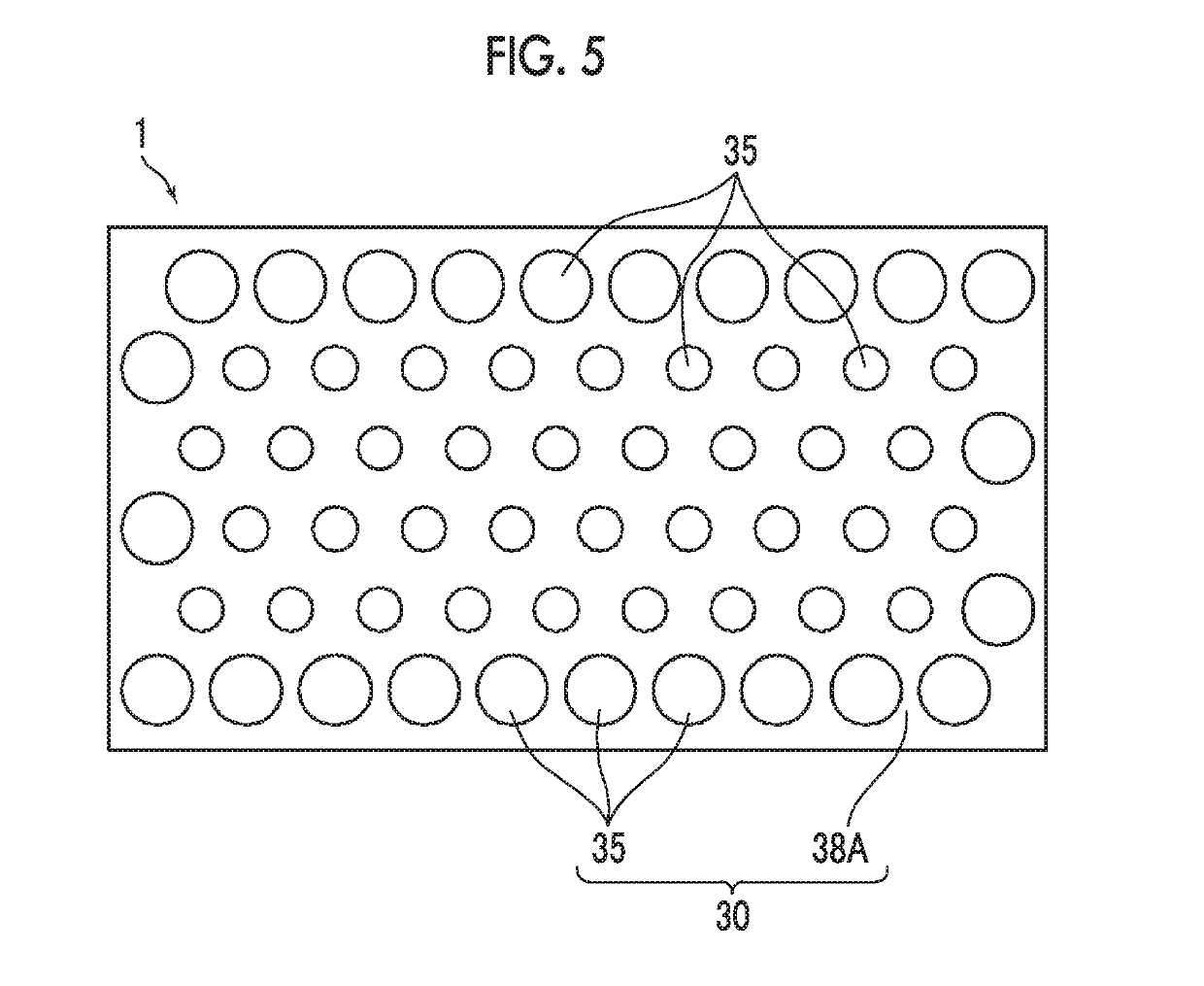

[0488]A resin layer was formed and a light absorbing material-containing film 2 was obtained in the same manner as in Example 1, except that the depth of all concave portions (light absorption regions) was 50 μm, and the concave portion was 500×500 μm (width of resin layer: 50 μm) in the region up to 1 cm inside including the ends of the four sides. That is, this example was configured such that a concave portion (light absorption region with width of 250 μm) in the central portion of 250×250 μm was surrounded by a concave portion (light absorption region with width of 500 μm) in the peripheral portion of 500×500 μm.

example 3

[0490]As the light absorbing material-containing film of the second aspect, a light absorbing material-containing film 4 was obtained in the same manner as in Example 1, except that a frame in place of the resin layer was formed in the following manner, and a light absorption region was formed in the frame.

[0491](Formation of Frame)

[0492]Individual components such as a curable compound, a polymerization initiator, a second light absorbing body, and scattering particles were mixed by a tank or the like to prepare a coating liquid as a coating liquid 3 for forming a frame.

[0493]—Composition of Coating Liquid 3 for Forming Frame—

[0494]A coating liquid for a frame having the following composition was prepared to obtain a coating liquid 3.

Tricyclodecane dimethanol diacrylate (A-DCP,75parts by massmanufactured by Shin-Nakamura Chemical Co.,Ltd.)YAG phosphor (ZYP 550G3 (YUJI LED10parts by mass(manufactured by Yuji International Co., Ltd.)))Synthetic plate-like alumina, average14parts by ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| modulus of elasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com