PVC disposable glove and manufacturing process thereof

a technology of pvc and disposable gloves, applied in the field of disposable gloves, can solve the problems of high pollution and high labor intensity, outdated manufacturing process, large amounts of a type of oil, etc., and achieve the effects of reducing production costs, reducing air pollution, and improving the working environment for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention is further described in details with the following specific embodiment example and the figure.

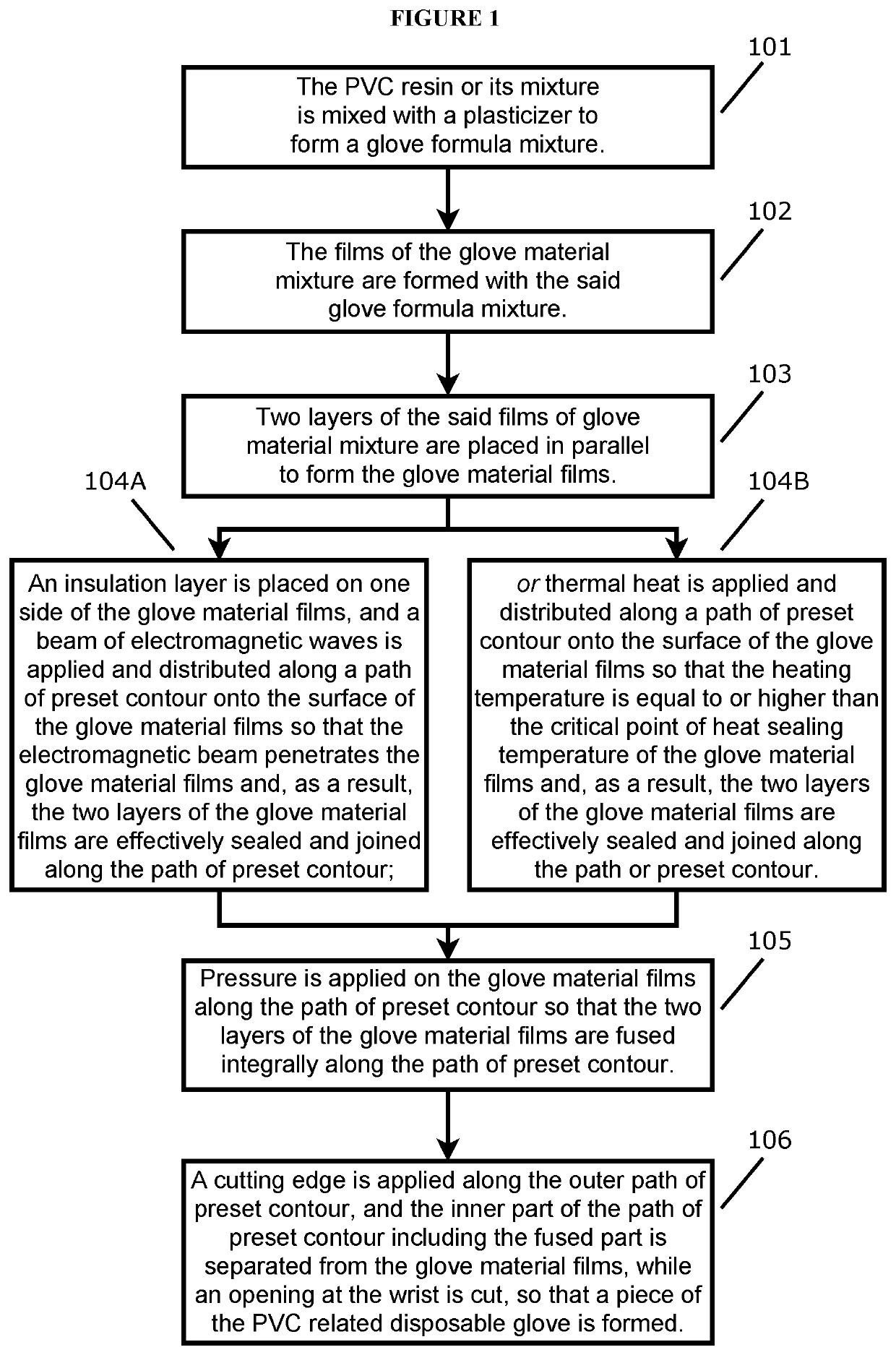

[0050]As shown in FIG. 1, the embodiment example of the present invention of the manufacturing process for the PVC related disposable gloves comprise the following steps:

[0051]Step 101, the PVC resin or its mixture is mixed with a plasticizer to form a glove formula mixture.

[0052]Step 102, the films of glove material mixture is formed with the said glove formula mixture.

[0053]Step 103, two layers of the said films of glove material mixture are placed in parallel to form the glove material films.

[0054]Step 104A, an insulation layer is placed on one side of the glove material films, and a beam of electromagnetic waves is applied and distributed along a path of preset contour onto the surface of the glove material films so that the electromagnetic beam penetrates the glove material films and, as the result, the two layers of the glove material films are effectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| frequencies | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com