Three-dimensional forming apparatus and three-dimensional forming method

a three-dimensional forming and forming apparatus technology, applied in additive manufacturing, solid and fluid additive manufacturing, additive manufacturing, etc., can solve problems such as sintering faults or melting faults, and achieve the effect of simple configuration and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

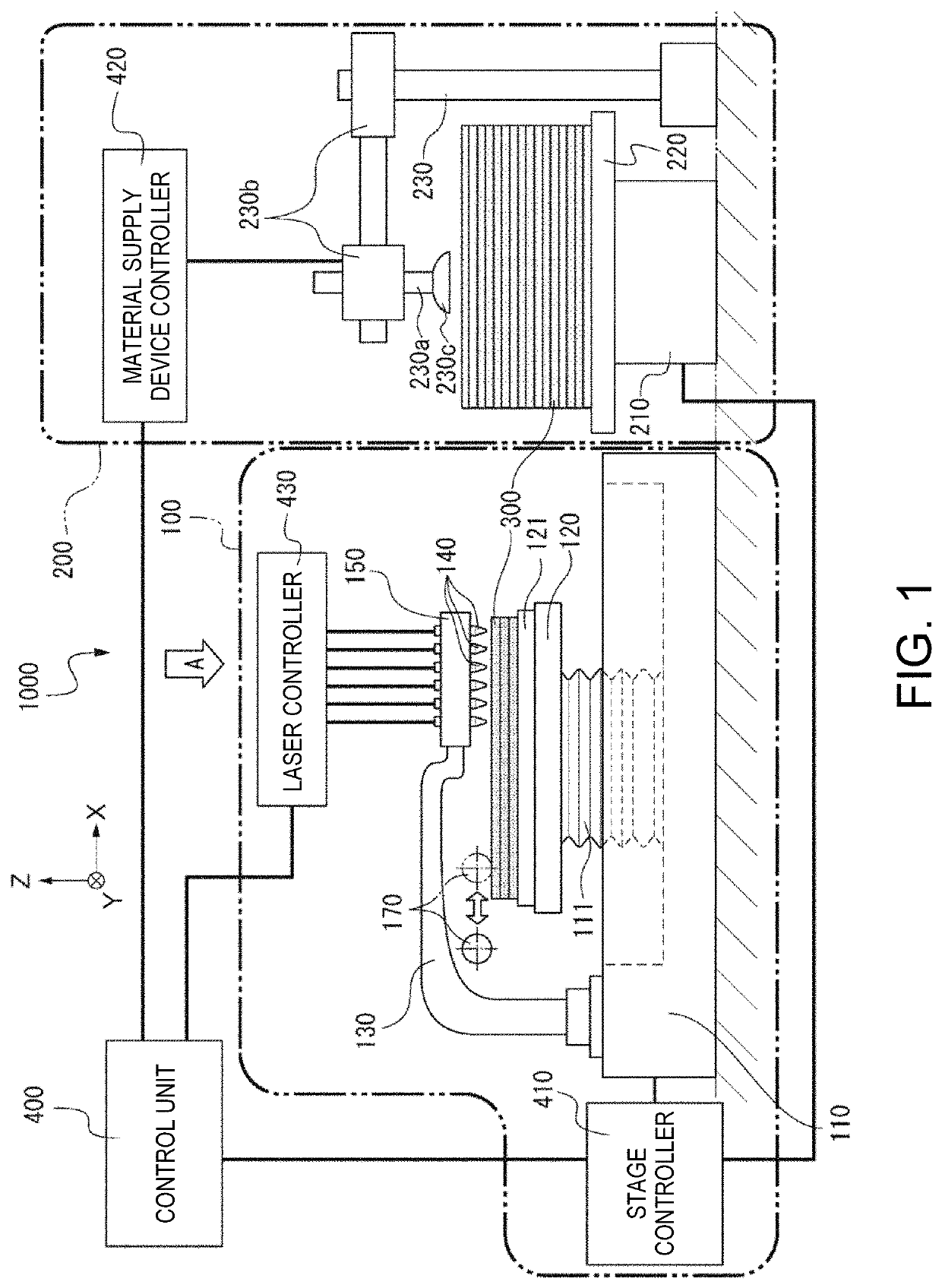

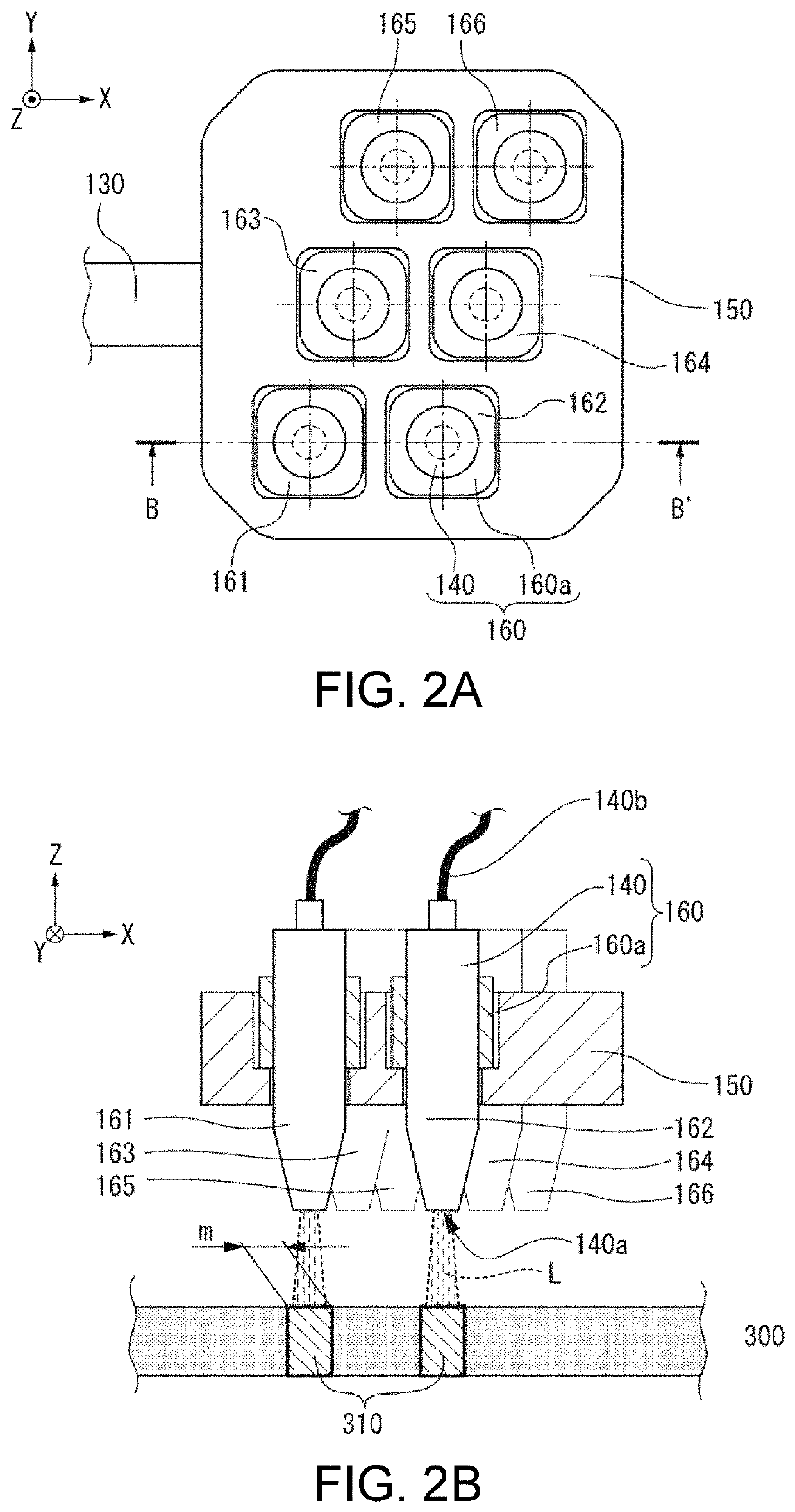

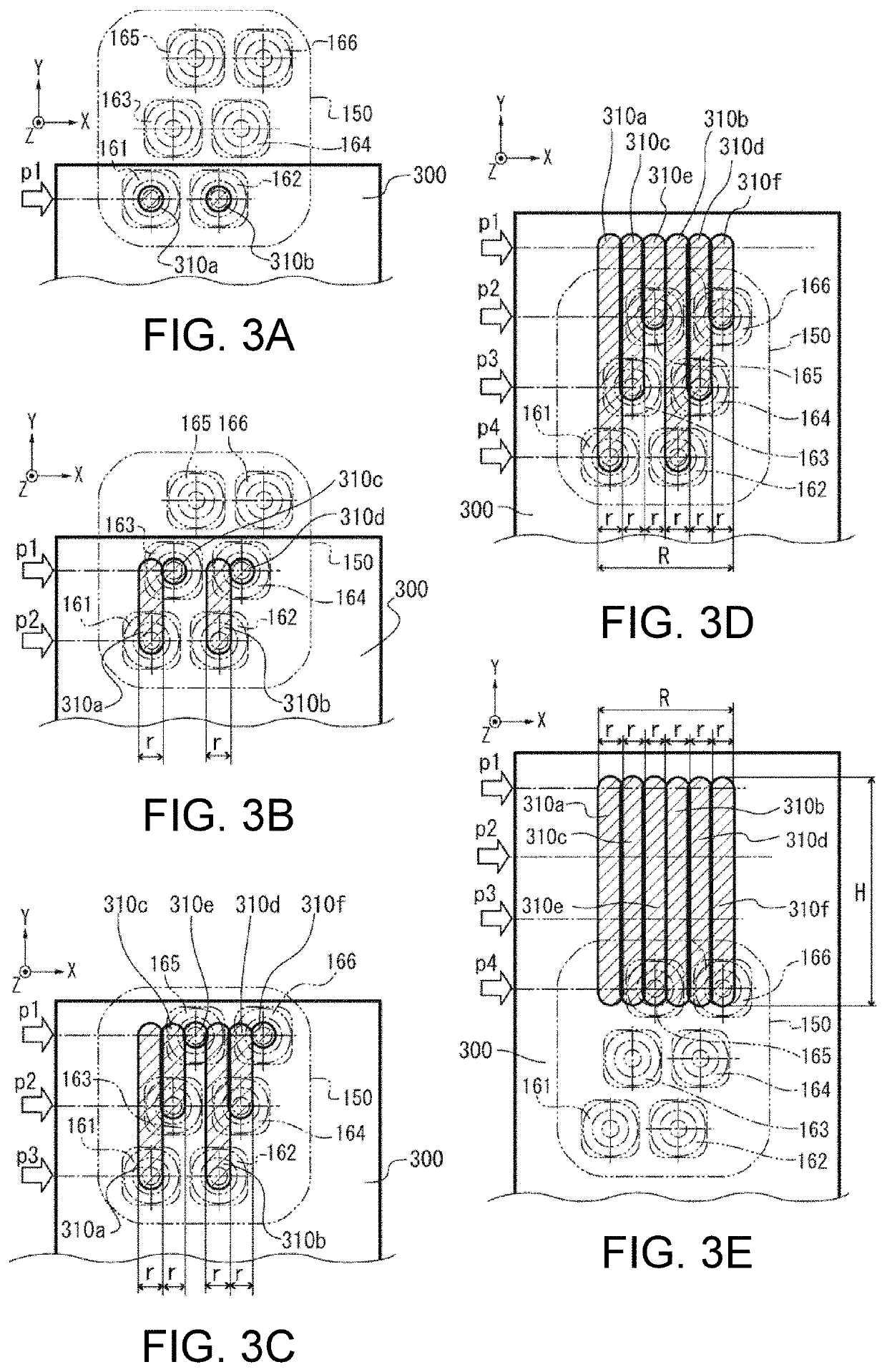

[0051]FIG. 1 is a schematic diagram illustrating the configuration of a three-dimensional forming apparatus according to a first embodiment. In the present specification, “three-dimensional forming” refers to forming a so-called stereoscopically fabricated object and includes, for example, forming a shape having a thickness even when the shape is a flat shape or a so-called two-dimensional shape.

[0052]A three-dimensional forming apparatus 1000 (hereinafter referred to as a forming apparatus 1000) illustrated in FIG. 1 includes a sintering device 100 that forms a three-dimensional fabricated object and a material supply device 200 serving as a material supply unit that supplies the sintering device 100 with supply material 300 (hereinafter referred to as a green sheet 300) called a so-called green sheet in which metal powder and a binder which are raw material of the three-dimensional fabricated object are kneaded and formed to a sheet shape.

[0053]The material supply device 200 inclu...

second embodiment

[0072]FIGS. 4A and 4B are schematic diagram illustrating the configuration of a three-dimensional forming apparatus according to a second embodiment. A three-dimensional forming apparatus 2000 (hereinafter referred to as a forming apparatus 2000) illustrated in FIG. 4A is different from the forming apparatus 1000 according to the first embodiment in the configuration of a material supply unit and the configuration of a head base and head units. Accordingly, the same reference numerals are given to the same constituent elements as those of the forming apparatus 1000 according to the first embodiment and the description thereof will be omitted.

[0073]As illustrated in FIGS. 4A and 4B, the forming apparatus 2000 includes a base 110, a stage 120 that can be moved in the illustrated X, Y, or Z direction or can be driven in a rotational direction about the Z axis by a driving device 111 serving as a driving unit included in the base 110, and a head base supporting unit 130 that has one end...

third embodiment

[0096]A three-dimensional forming method of forming a three-dimensional fabricated object using the three-dimensional forming apparatus 1000 according to the first embodiment will be described according to a third embodiment. FIG. 11 is a flowchart illustrating the three-dimensional forming method according to the third embodiment. FIG. 12 is a schematic diagram illustrating the configuration of a green sheet forming apparatus that forms the green sheet 300. FIGS. 13A, 13B, 14A, and 14B are schematic plan views and sectional views illustrating steps of the three-dimensional forming method according to the embodiment. FIGS. 15E and 15F are external perspective views and schematic sectional views illustrating steps of the three-dimensional forming method according to the embodiment.

Three-Dimensional Fabrication Data Acquisition Process

[0097]As illustrated in FIG. 11, in the three-dimensional forming method according to the embodiment, a three-dimensional fabrication data acquisition p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com