Automatic sand abrasion device

a sand abrasion and automatic technology, applied in the direction of instruments, manufacturing tools, material analysis, etc., can solve the problems of high manpower and material resources, low detection capacity and accuracy, and low efficiency, so as to improve the detection efficiency of sand abrasion resistance, reduce labor costs, and improve the effect of accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

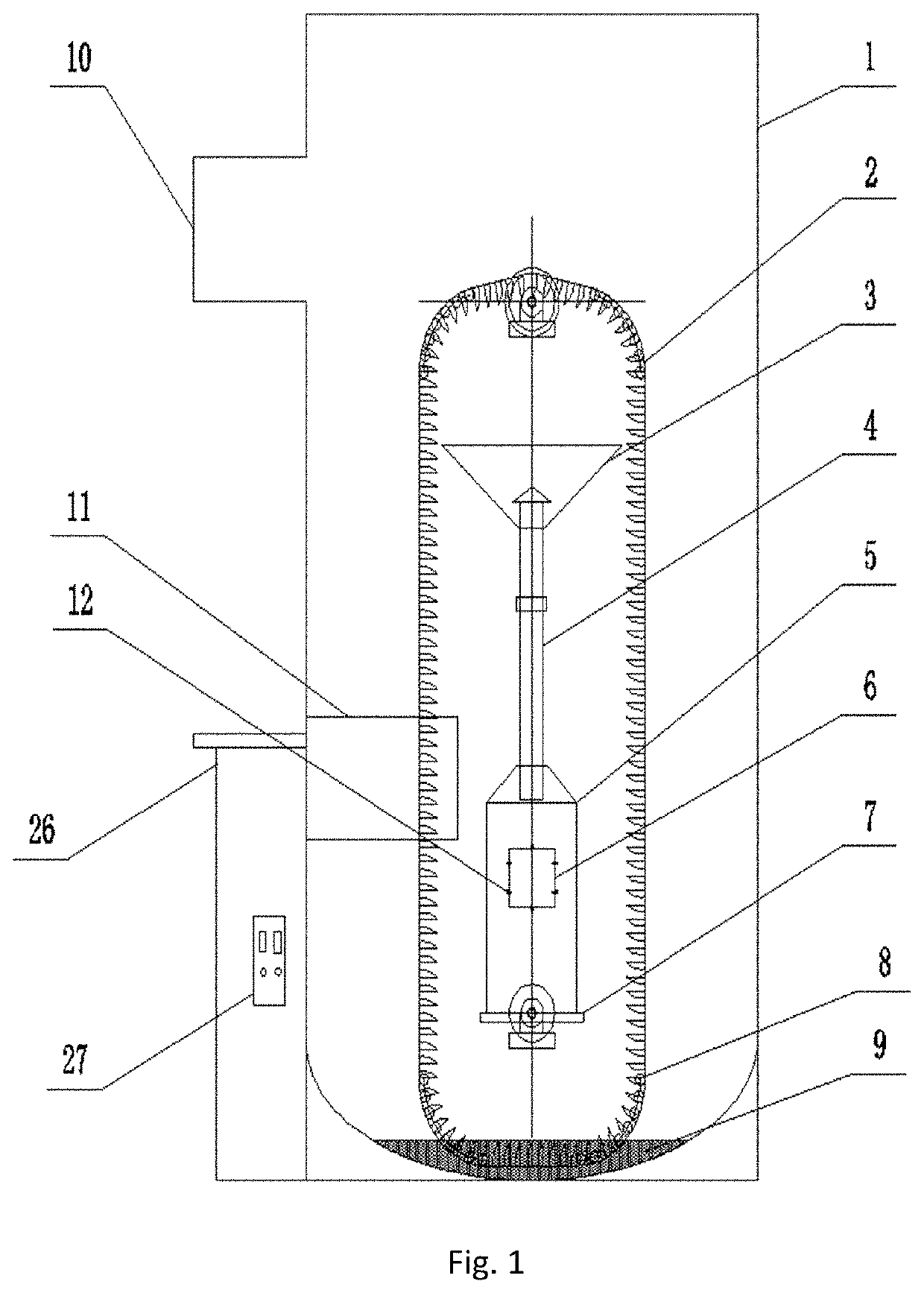

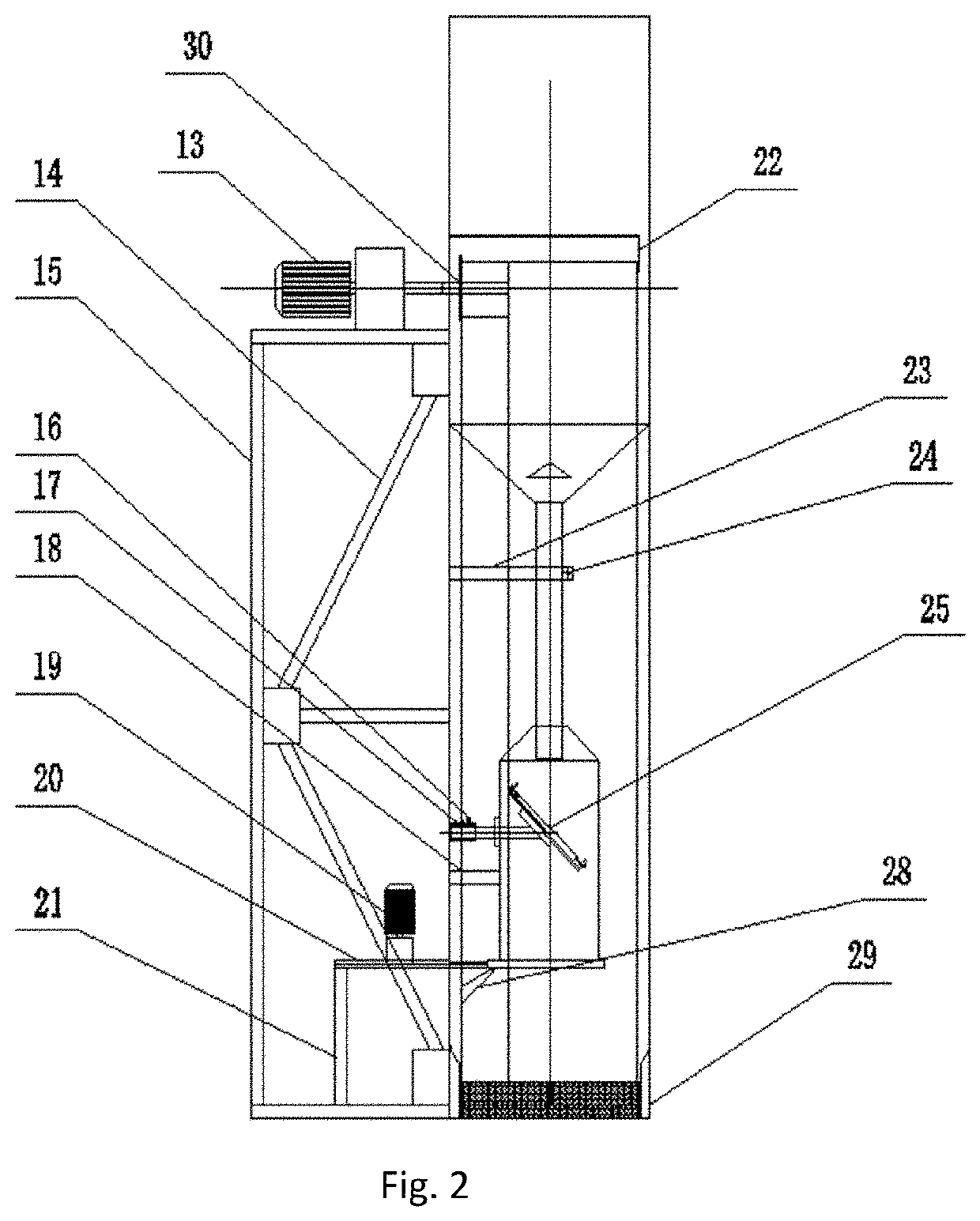

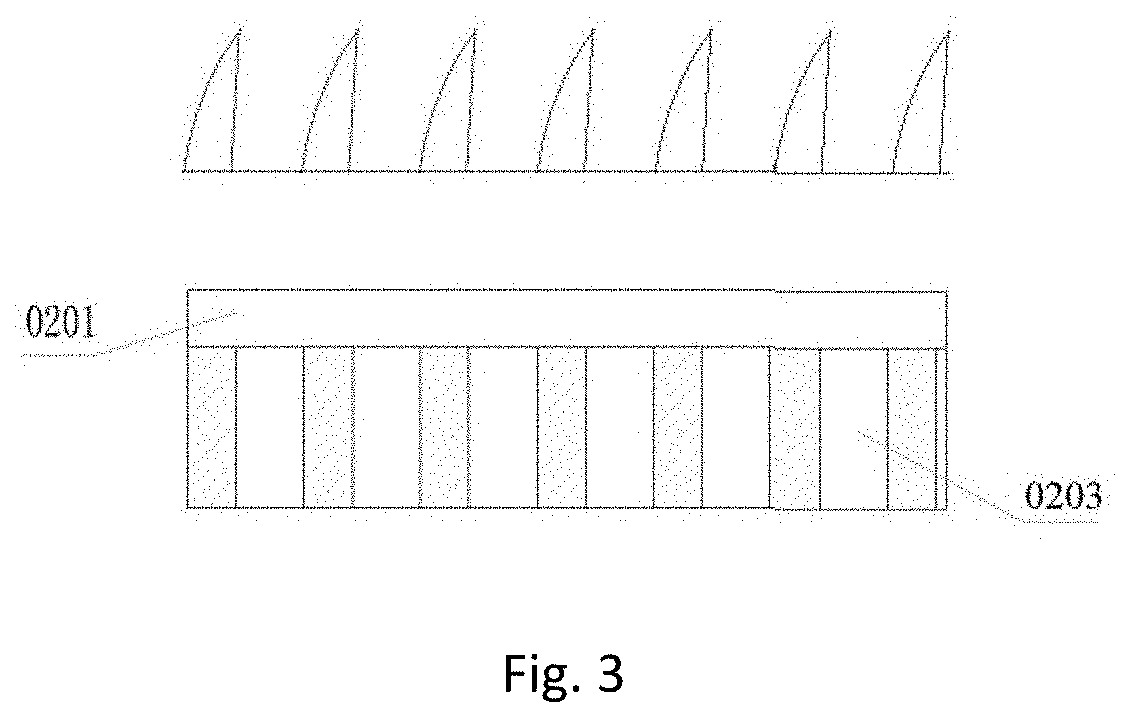

[0030]Referring to FIGS. 1 to 7, one embodiment provided by the present disclosure is as follows.

[0031]An automatic sand abrasion device is characterized by including a shell 1, an integrated framework, a sand falling mechanism, a sand transport mechanism, a sand falling channel, a sample working frame and a circuit control cabinet 26. The integrated framework includes an experiment table supporting frame 15, supporting rods 14 and a weighing machine bracket 21. The weighing machine bracket 21 is fixedly mounted at the bottom in the experiment table supporting frame 15. The supporting rods 14 are fixedly disposed in the experiment table supporting frame 15 to allow the integrated framework to be firmer. In the present embodiment, the supporting rods and the weighing machine bracket are welded inside the experiment table supporting frame. The shell 1 is welded on the experiment table supporting frame 15, and the integrated framework, the sand falling mechanism, the sand transport mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com