Substrate polishing device and substrate polishing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Embodiments of a partial polishing device according to the present invention will be described referring to the attached drawings. In the attached drawings, the same or similar components will be designated with the same or similar reference signs, and repetitive explanations of the embodiments, thus will be omitted from description of the respective embodiments. Features to be described in the respective embodiments may be applied to other embodiments so long as those features do not mutually conflict.

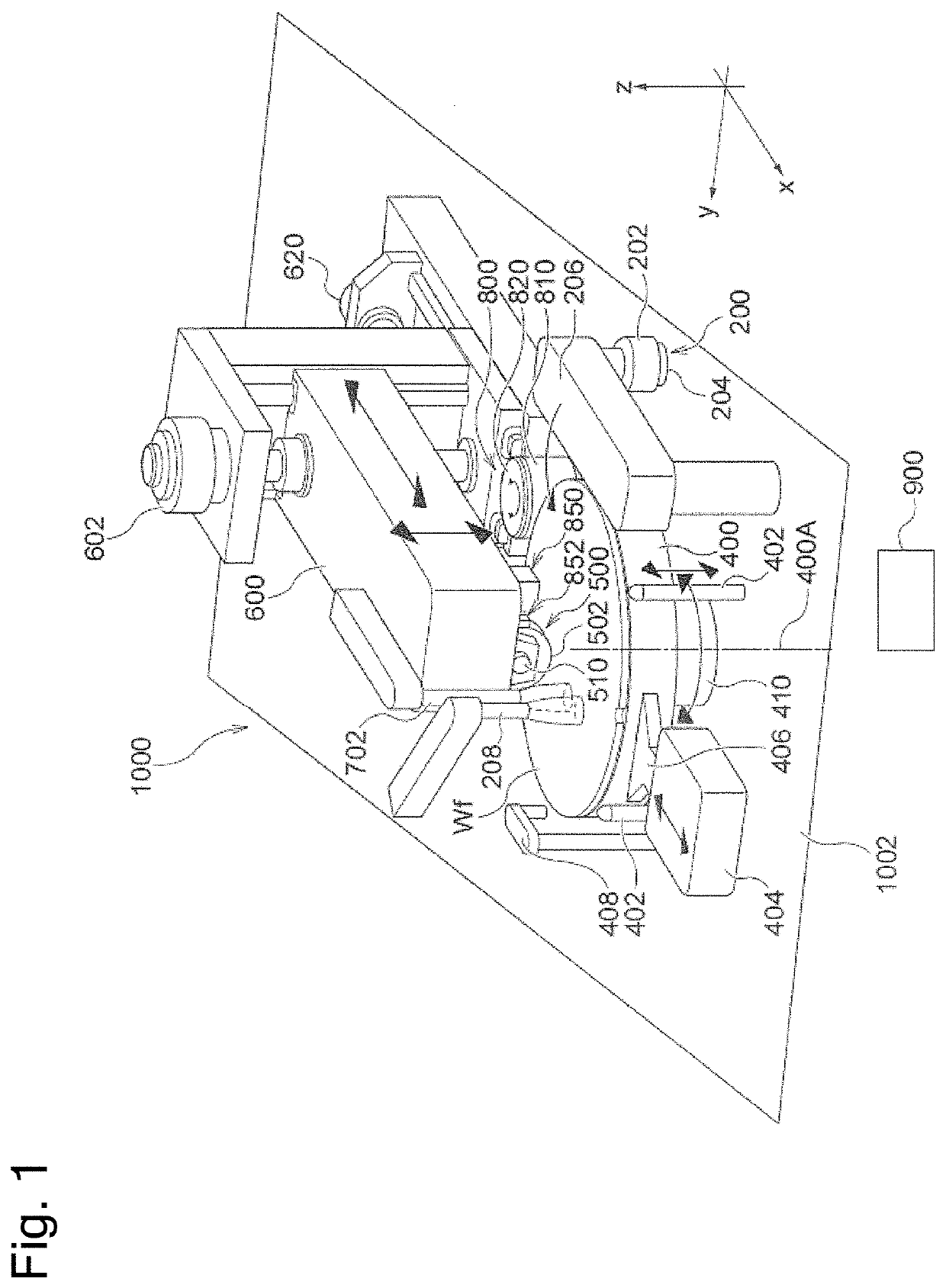

[0043]FIG. 1 is a schematic view showing a structure of a partial polishing device 1000 according to an embodiment. As FIG. 1 shows, the partial polishing device 1000 is formed on a base surface 1002. The partial polishing device 1000 may be formed as an independent device, or as a module constituting a substrate processing system 1100 including a large-diameter polishing device 1200 using a large-diameter polishing pad together with the partial polishing device 1000 (see FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com