Friction-assisted tube fabrication method

a technology of friction-assisted tube and fabrication method, which is applied in the field of friction-assisted tube fabrication method, can solve the problems of inability to apply conventional processes and methods in an industrial scale, the limitation of processing metal objects, and the increase of equipment and high processing force and power, so as to achieve easy softening, simple increase the radius of the tube, and the effect of softening the deformation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

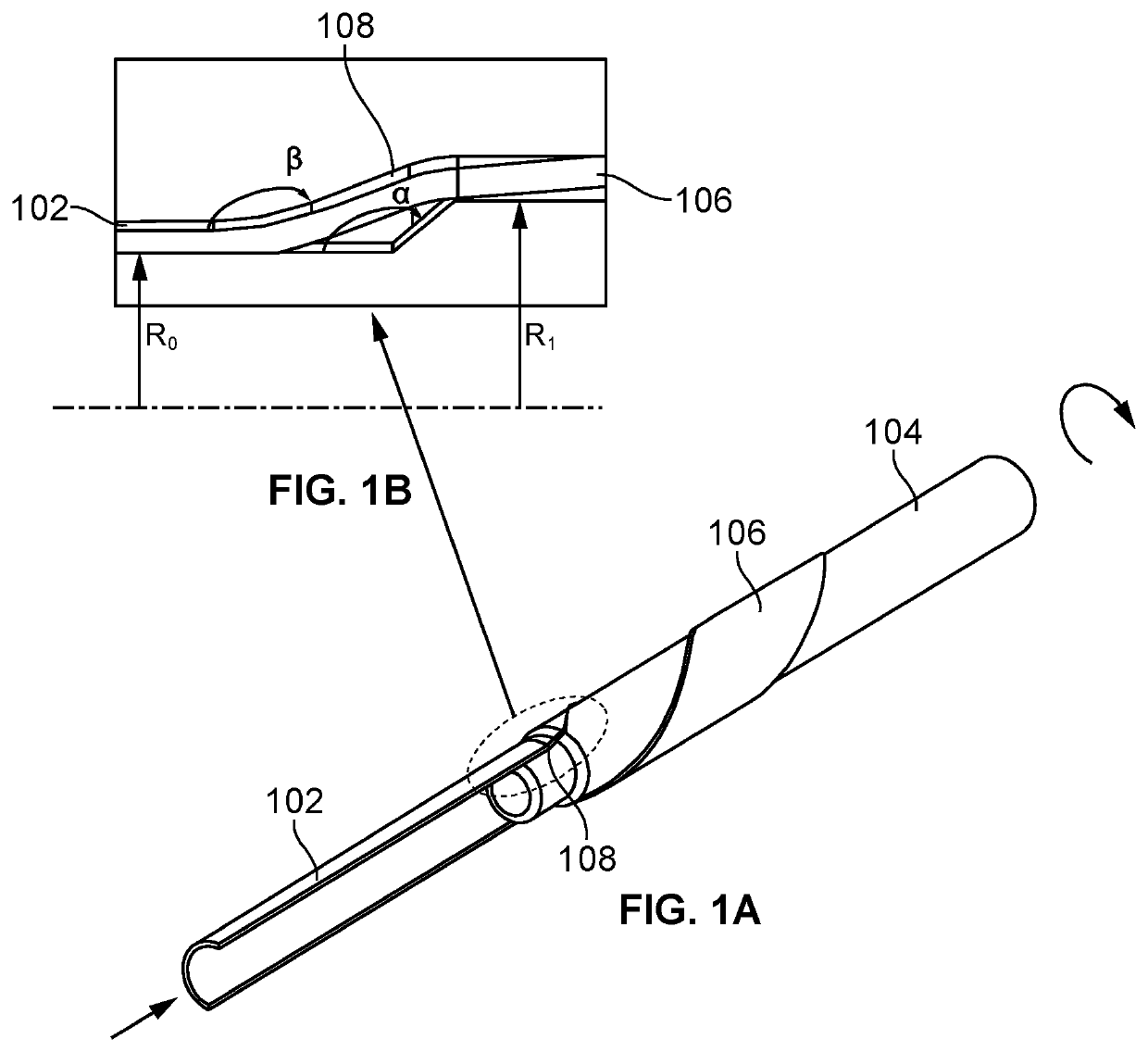

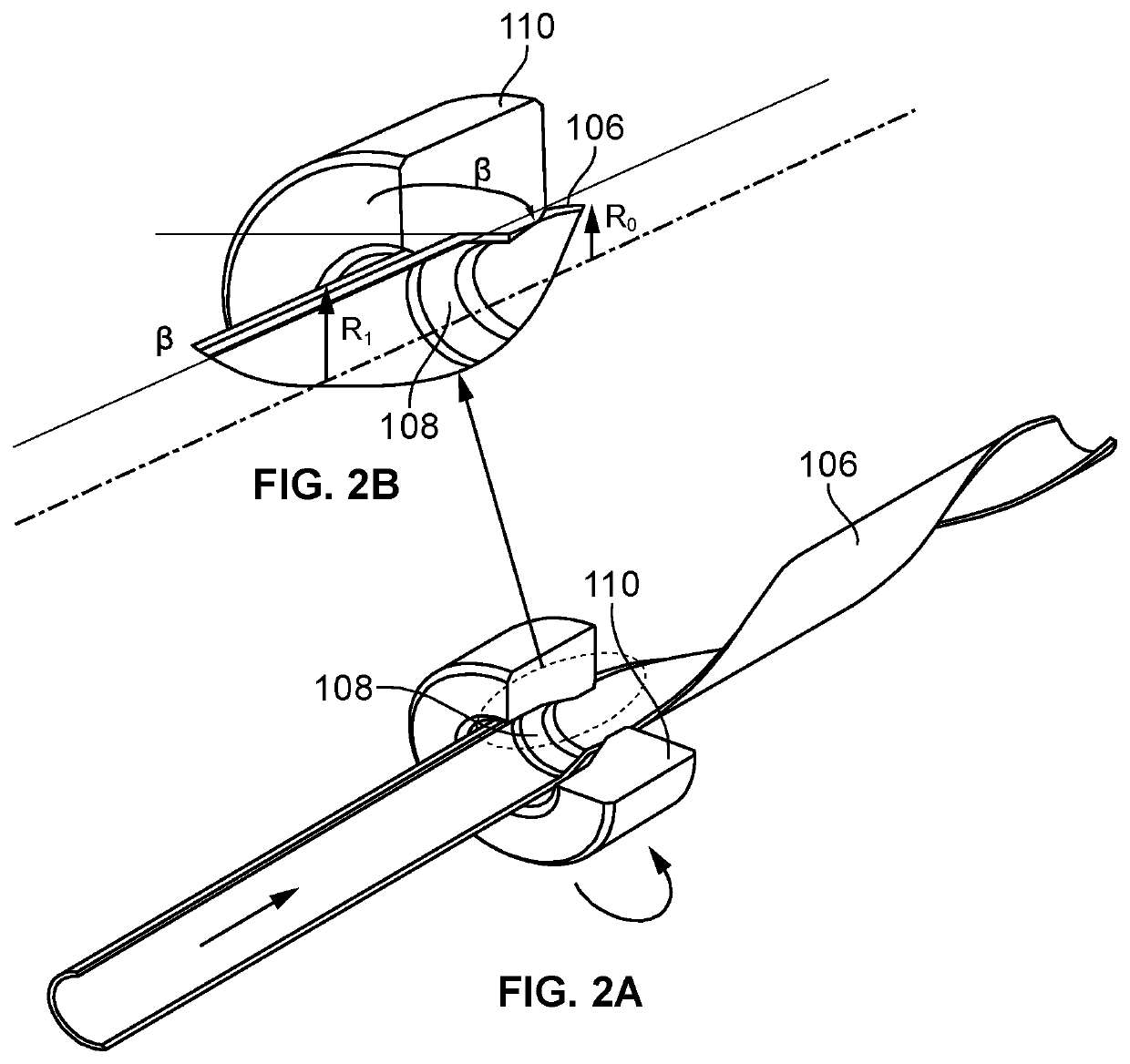

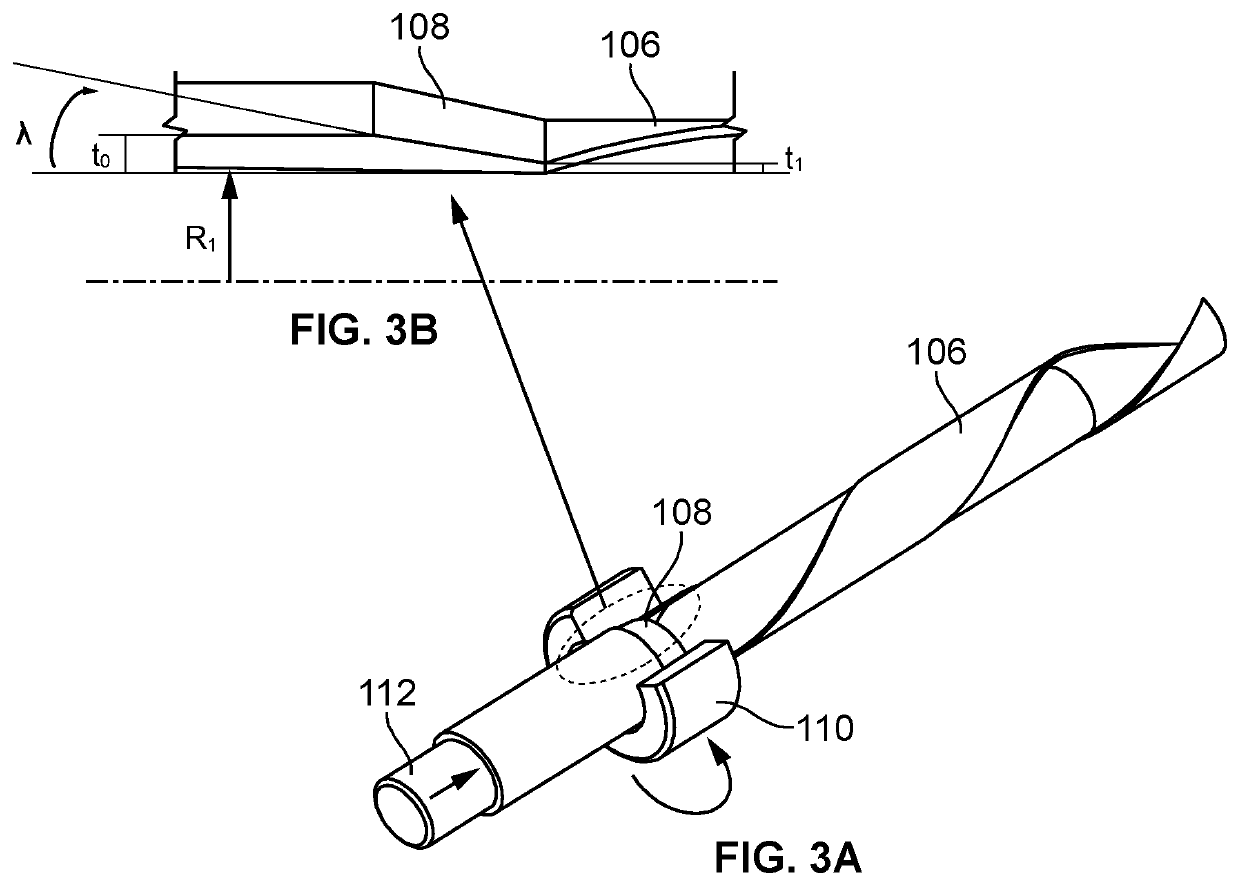

[0030]The present invention generally relates to a method for fabricating elongated members and tubular products and more particularly relates to a friction-assisted tube fabrication method used to produce high-strength elongated members and tubular products, wherein the friction-assisted tube fabrication method includes a set of processes or methods such as a friction assisted tube forming method, a friction assisted tube extrusion / extruding method, and a friction assisted tube straining method.

[0031]A description of embodiments of the present invention will now be given with reference to the figures. It is expected that the present invention may be embodied in other specific forms without departing from its spirit or essential characteristics. The described embodiments are to be considered in all respects only as illustrative and not restrictive. The scope of the invention is, therefore, indicated by the appended claims rather than by the foregoing description. All changes that co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com