Split gate structure, power mos device, and manufacturing method

a technology of split gate and power mos, which is applied in the field of split gate structure and power mos device, can solve the problems of split gate power mos igss performance and power consumption of electric devices, and achieve the effect of improving breakdown performance and igss performance of split gate power mos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be described in detail through the following embodiments with appending drawings such that the objectives, technical solutions, and advantages of the present invention will be more clear. It should be understood that the specific embodiments are provided for an illustrative purpose only, and should not be interpreted in a limiting manner.

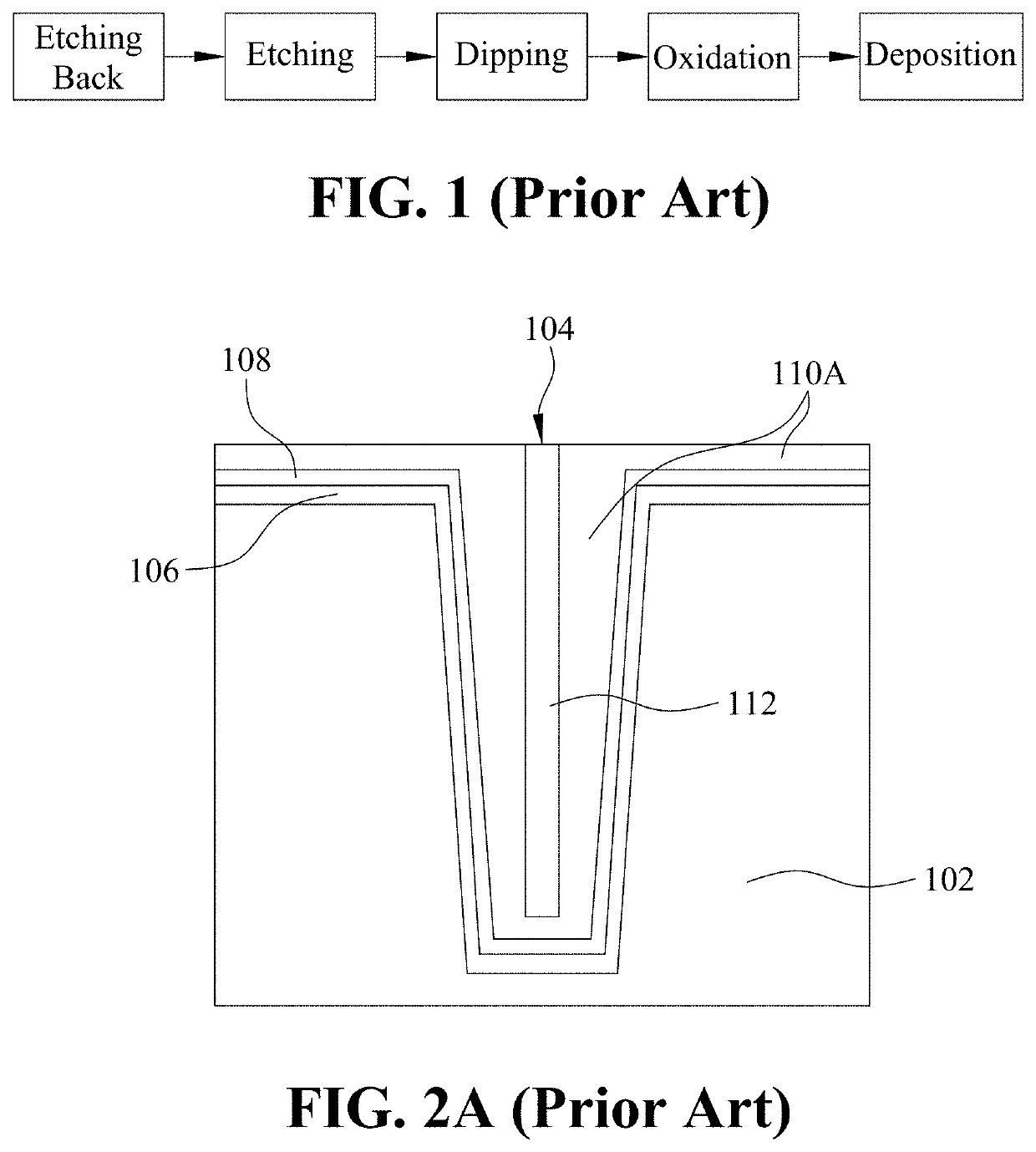

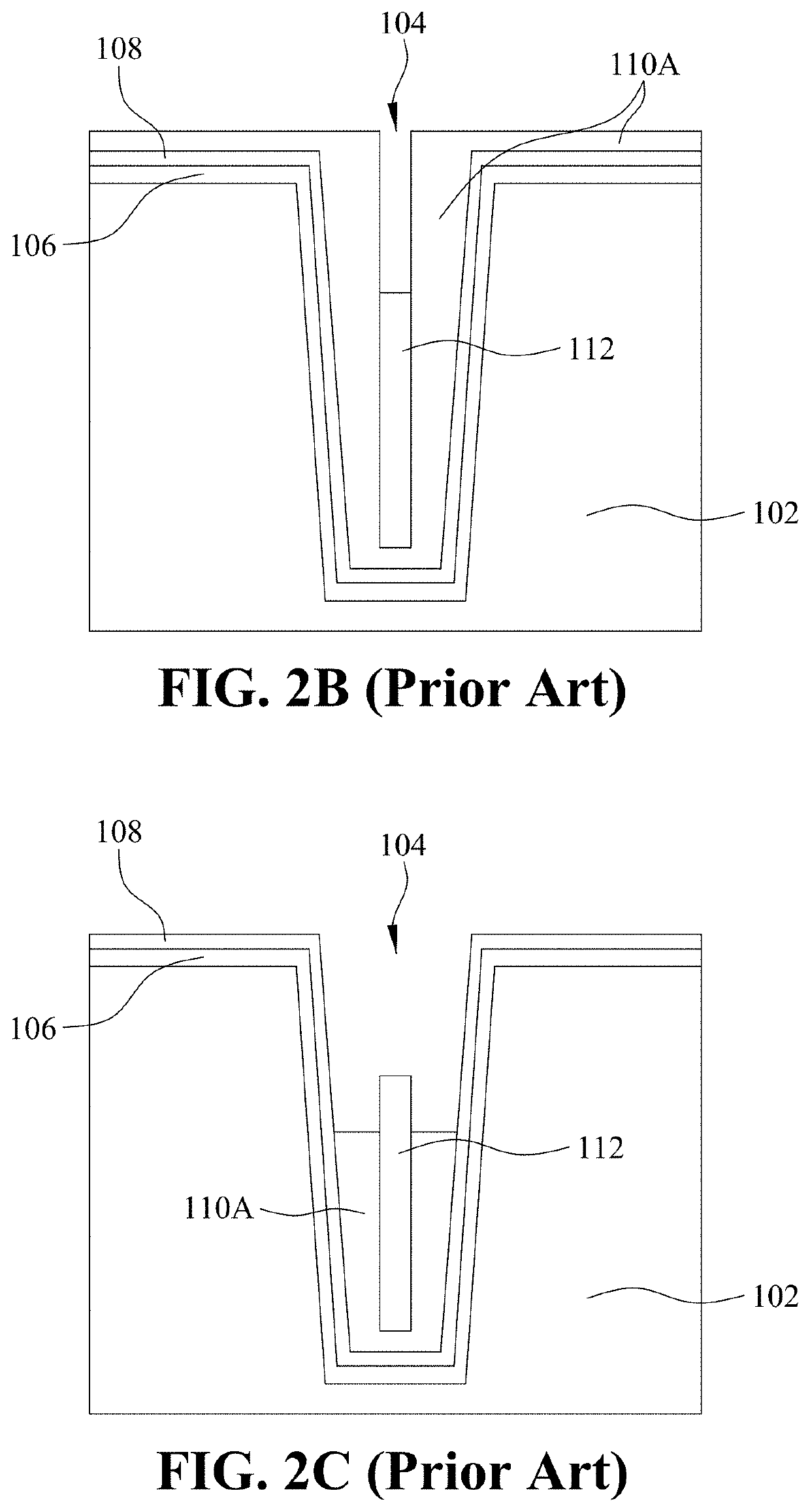

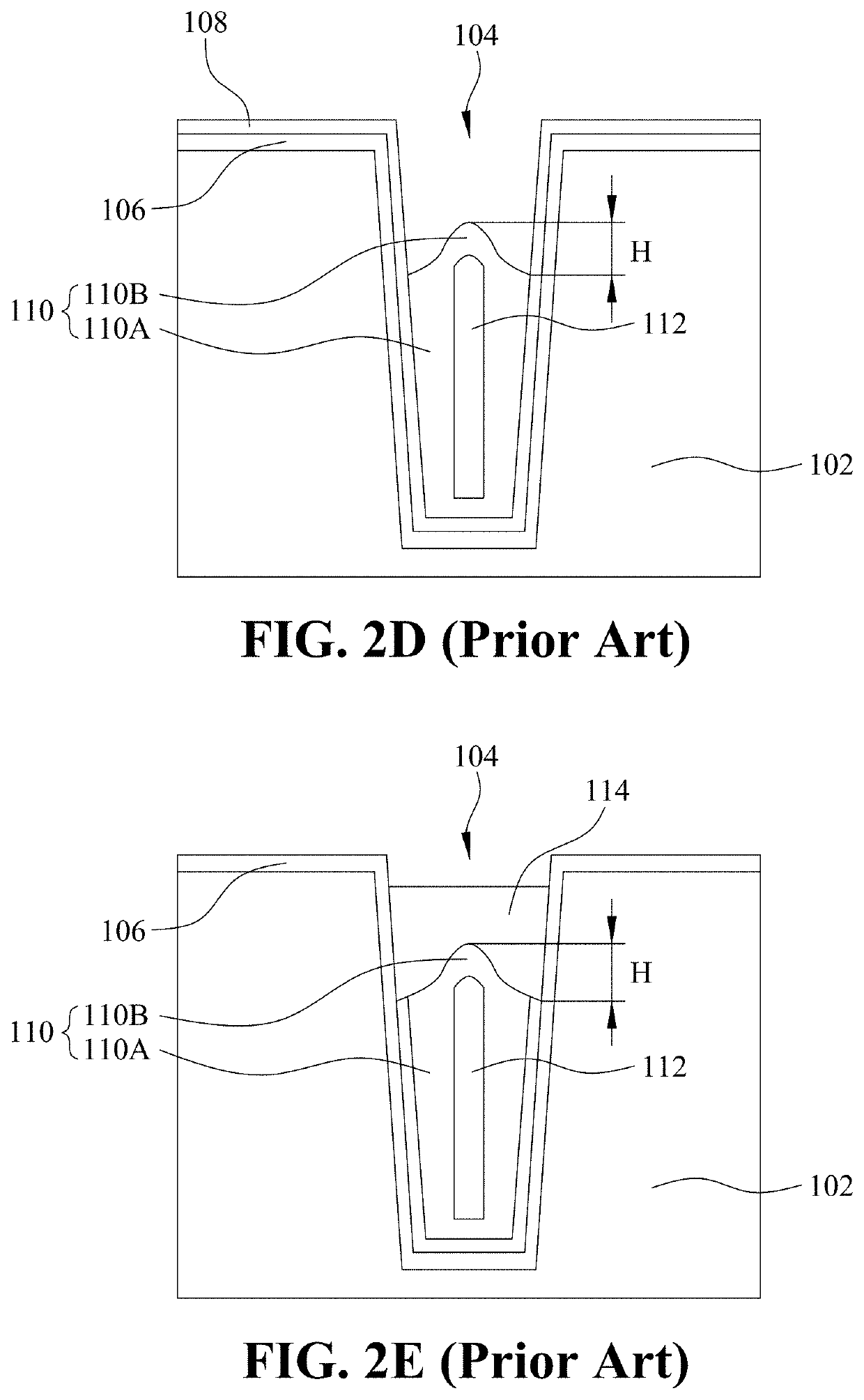

[0026]As illustrated in FIG. 1 and FIGS. 2A-2E, a conventional manufacturing method typically comprises the processes of etching back-etching-dipping-oxidation-deposition. Specifically, an etching back process is firstly performed on a first polysilicon 112 in a trench 104 with a characteristic oxide 110A on a wall thereof such that the first polysilicon 112 has a height higher than a depth of the trench 104 (FIG. 2A). Then, a first etching process is performed on the first polysilicon 112 such that the first polysilicon 112 has a height lower than the depth of the trench 104 (FIG. 2B). A dipping step is performed, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com