Multi-axis processing machine and rotation center measurement method of multi-axis processing machine

a multi-axis processing machine and measurement method technology, applied in computer control, program control, instruments, etc., can solve the problems of large impact on the processing precision of workpieces, increase in the number of geometric deviations between axes, and occur geometric errors (a geometric deviation). the effect of capital investmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

[0031](1. Overall Configuration of Five-Axis Processing Machine 100)

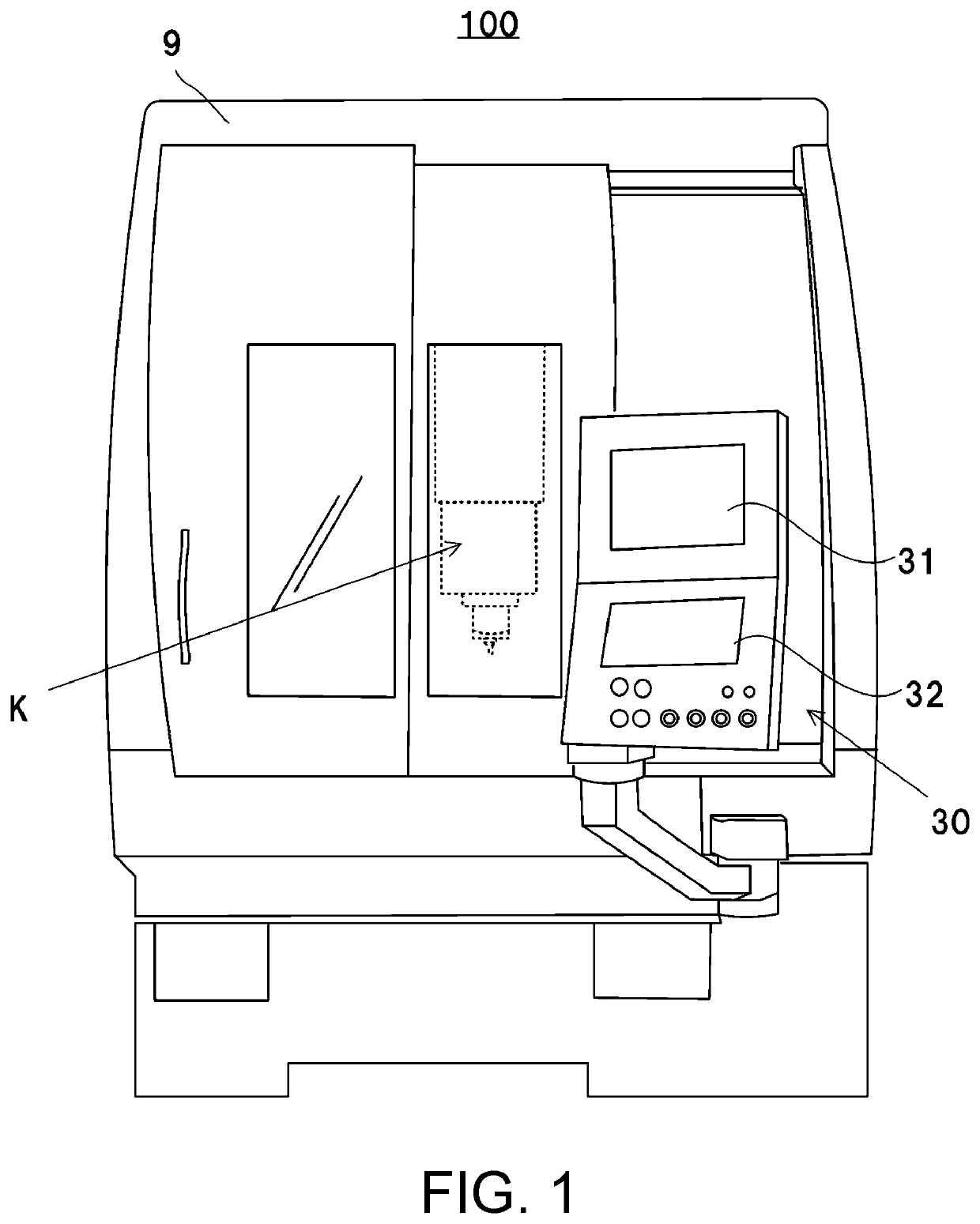

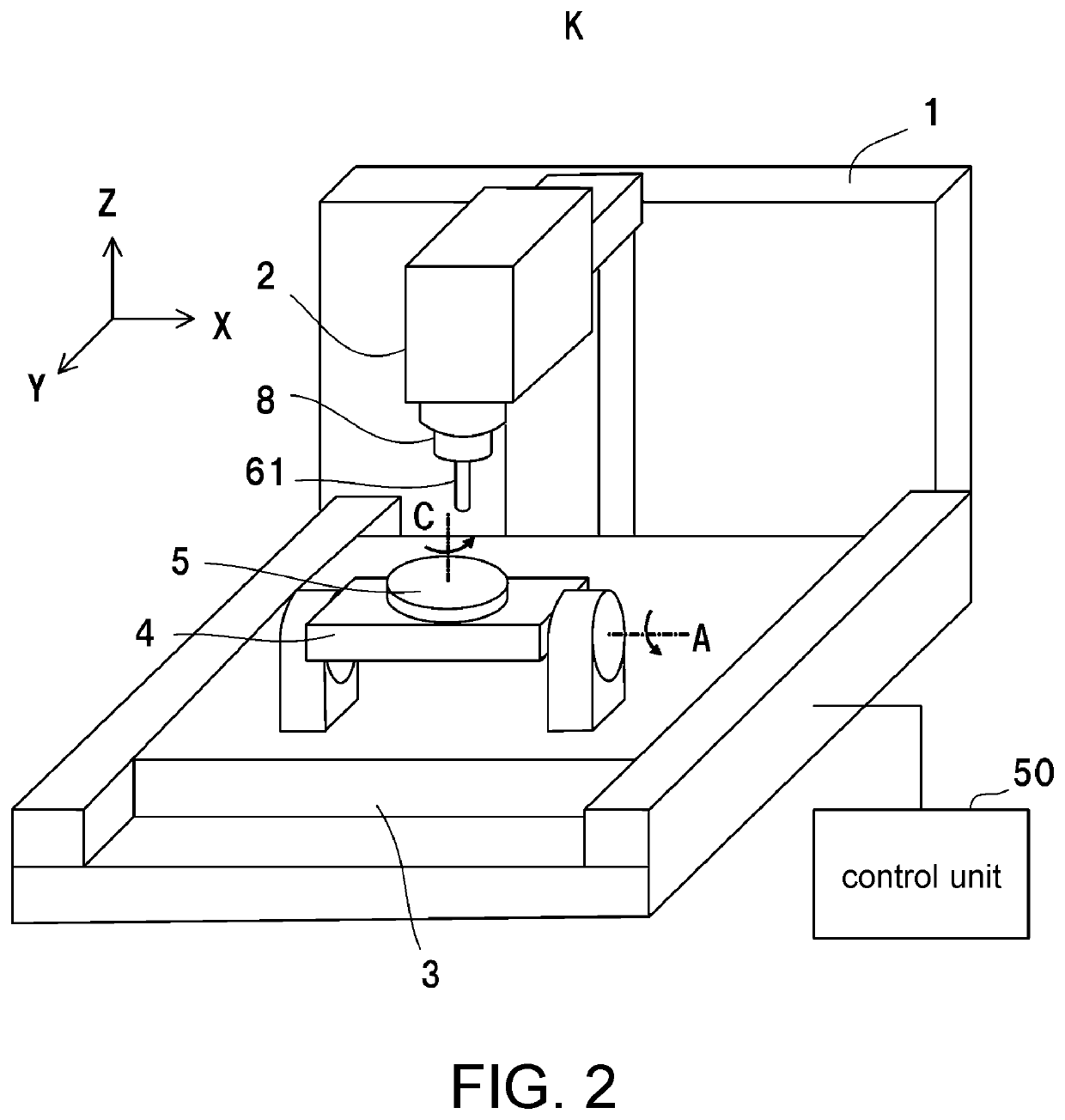

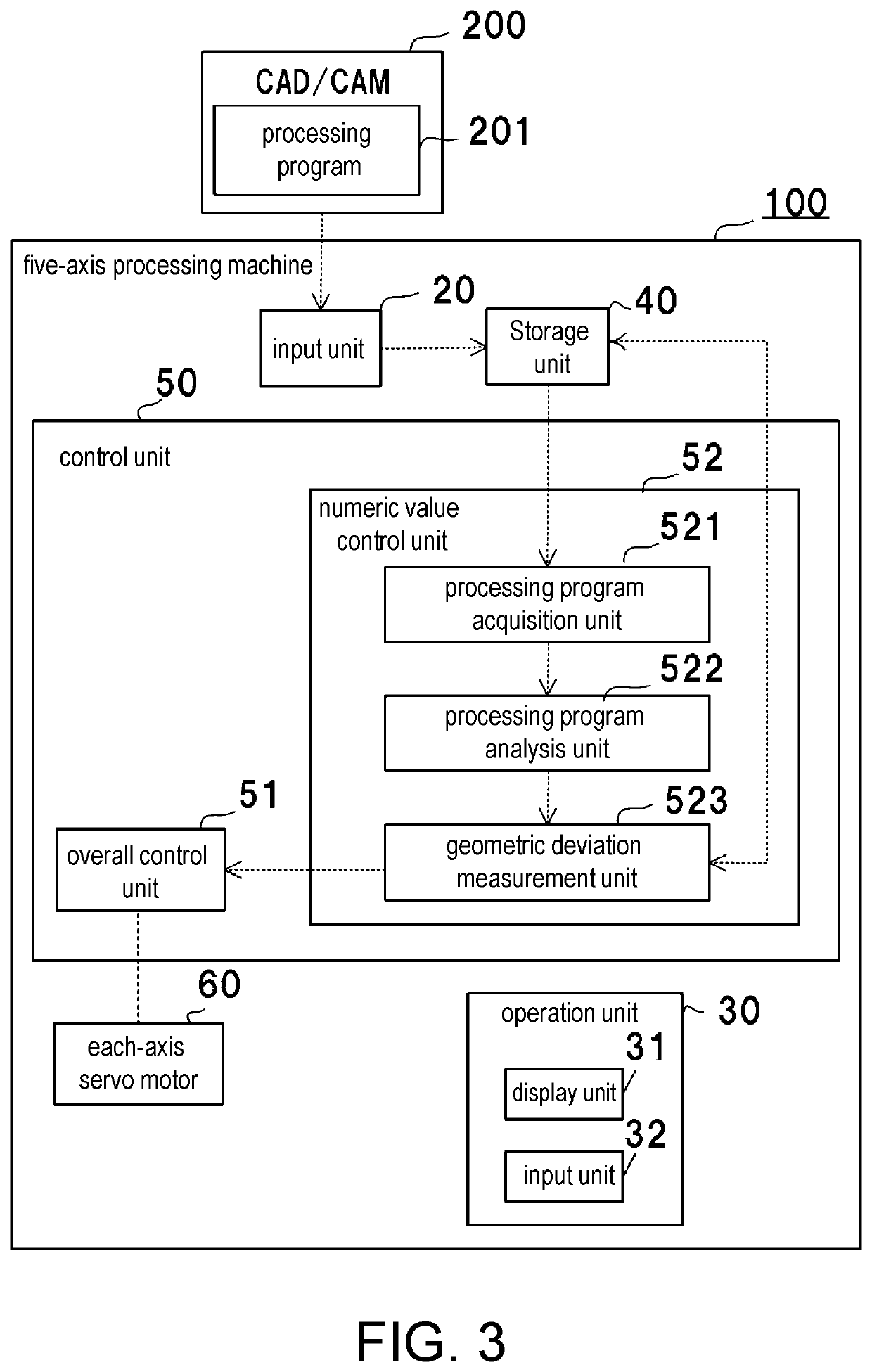

[0032]A configuration of the five-axis processing machine 100 is described with reference to FIGS. 1, 2 and 3. FIG. 1 is a schematic diagram of the five-axis processing machine 100 according to a first embodiment of the disclosure, and FIG. 2 is a schematic diagram showing an internal structure of the five-axis processing machine 100 according to the embodiment.

The five-axis processing machine 100 is a processing machine that performs control of five axes including three linear axes of an X-axis, a Y-axis, and a Z-axis and two rotation axes, and the five-axis processing machine 100 is a table swivel type that swivels a work piece W together with a tilt table 4. The X-axis, the Y-axis, and the Z-axis orthogonal to each other are set for the five-axis processing machine 100, an A-axis is set as a rotation axis around an axial center that extends parallel to the X-axis, and a C-axis is set as a rotat...

second embodiment

1. Second Embodiment

[0068]FIG. 16 is a block diagram of a five-axis processing system 500 according to a second embodiment of the disclosure. Moreover, in each drawing and each embodiment described in the specification, the same reference signs are given to the same configuration elements, and description thereof is omitted as appropriate.

[0069]The five-axis processing system 500 is configured by an analysis device 400, the CAD / CAM device 200, and a five-axis processing machine 300, and each device is connected via a network 600.

[0070]The network 600 is a communication network such as the Internet, LAN, or the like, and transmits information by wire or wirelessly.

[0071]The analysis device 400 is a device that acquires the processing program 201 from the CAD / CAM device 200 via the network 600, calculates measurement angles for each rotation axis from the processing program 201, and transmits the measurement angles to the five-axis processing machine 300.

The analysis device 400 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com