Method for balancing the out-of-balance of a shaft/wheel assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

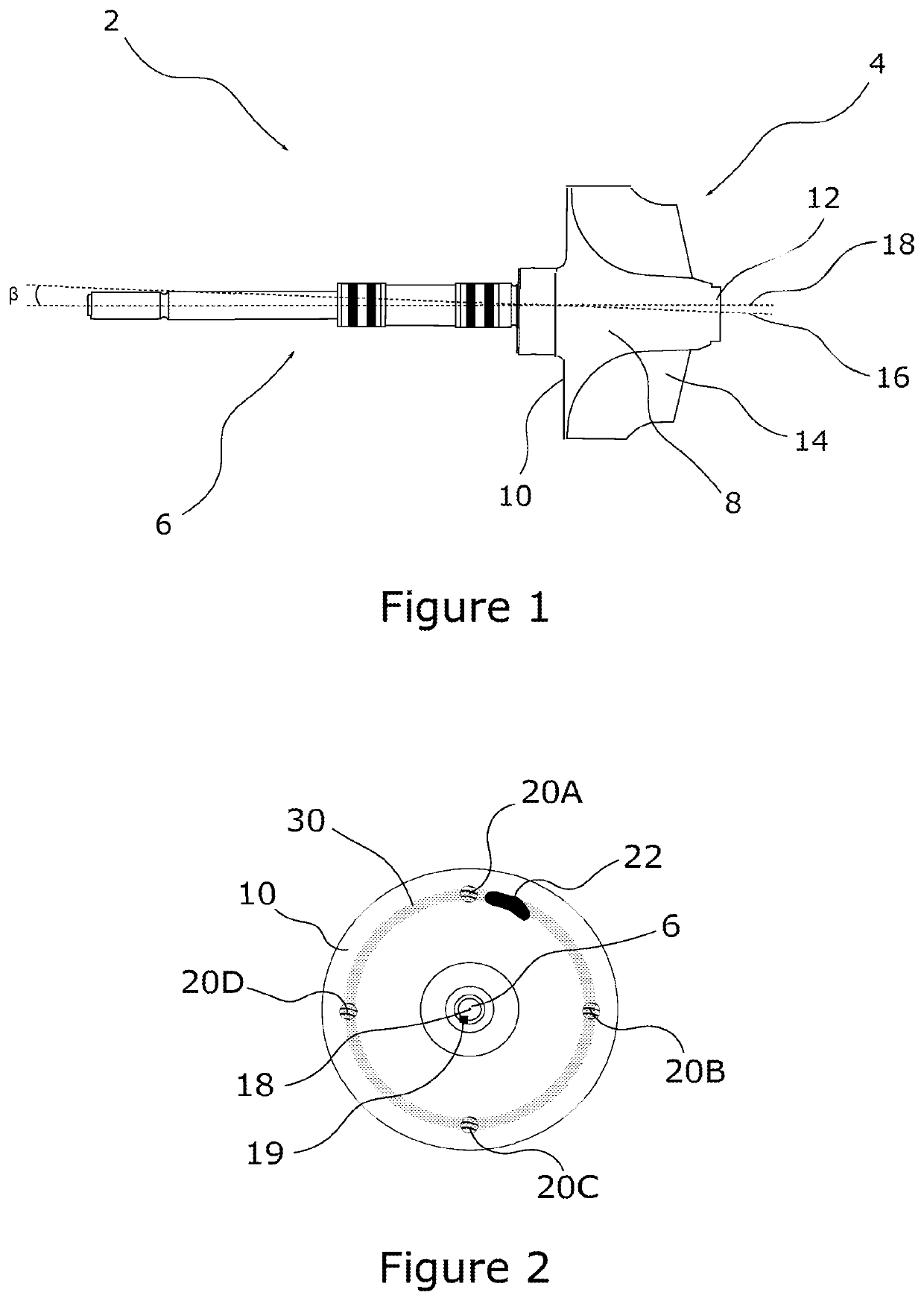

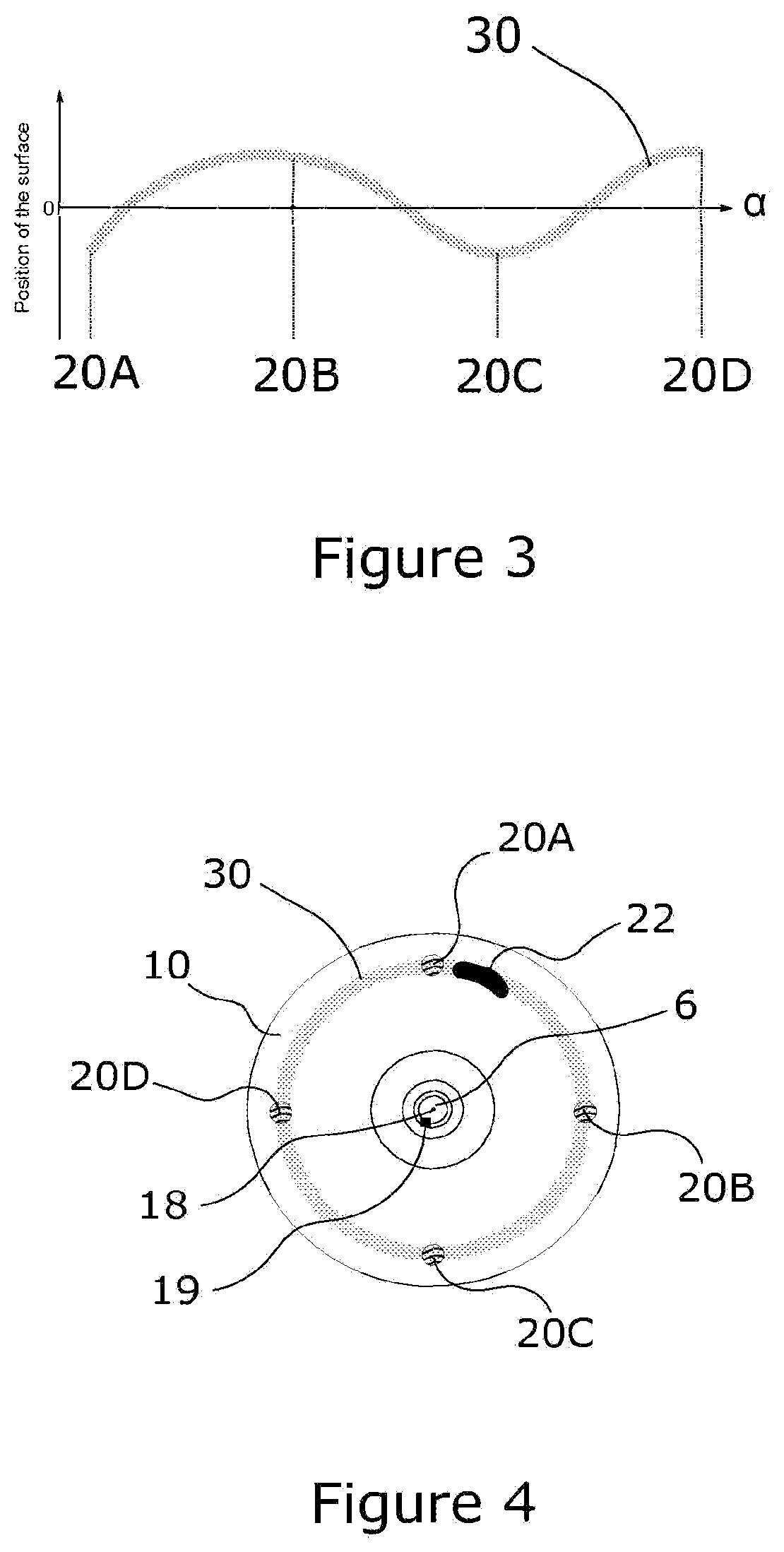

[0039]According to the invention, it is meant by shaft-wheel assembly 2, a bladed wheel 4 held at the end of a mechanical shaft 6, as illustrated in FIG. 1. As known, a bladed wheel comprises a hub 8 of conical or substantially conical shape, extending between a rear face 10 and a nose 12. The bladed wheel includes a plurality of wings 14 extending radially from the hub 8. The wings are distributed at regular intervals about said hub, so as to enable a flow of air to make the bladed wheel 4 pivoting about an axis of rotation 16, passing through the centre of the rear face 10 and the centre of the hub nose 12.

[0040]The bladed wheel 4 is usually a casted part whose raw surface prevents an accurate welding of the latter on one end of the mechanical shaft 6. That way, the axis of rotation 16 of the bladed wheel and the axis of rotation 18 of the mechanical shaft 6 are slightly offset with respect to each other and inclined by an angle β as illustrated in FIG. 1. The centre of inertia 19...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap