Agricultural sprayer with warm water rinse system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

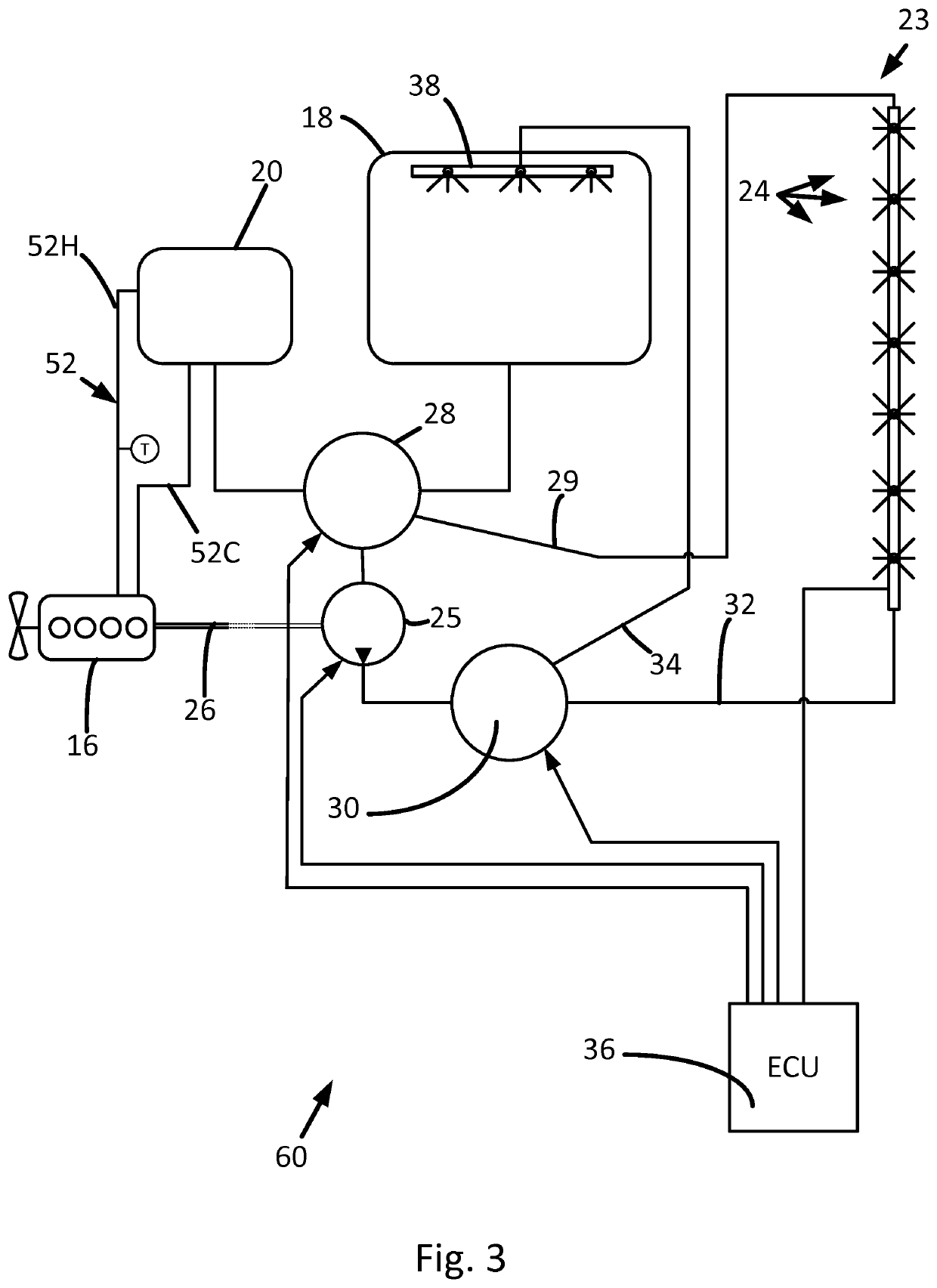

[0047]With reference to FIG. 3 a spray system 60 uses a different heat exchange system to that shown in FIG. 2 and described above in relation to heating the rinse fluid. In this embodiment, waste heat from the engine 16 is recovered and transferred directly to the rinse fluid.

[0048]The heat exchange system 52 uses the rinse fluid itself as a heat exchange medium by transporting the rinse fluid from the rinse tank 20 to a heat exchanger associated with engine 16 and returning the heated fluid to the rinse tank 20. The fluid circuit comprises a heated line 52H and a cooled line 52C. The fluid may be circulated by a water pump (not shown) drivingly connected to the engine 16.

third embodiment

[0049]With reference to FIG. 4, a spray system 70 uses waste heat from parts of an on-board hydraulic system, in this case the pump 25. It should be understood that engine 16 and the input manifold control line have been omitted from FIG. 4 only for reasons of clarity. In this embodiment, waste heat from the pump 25 is recovered and transferred directly to the rinse fluid.

[0050]A heat exchange system 62 comprises a heat exchanger 64 that is mounted proximate to, or integrated with, the pump 25. The heat exchanger 64 is connected in a fluid circuit having a heated line 62H and a cooled line 62C. The cooled line 62C conveys rinse fluid from rinse tank 20 to the heat exchanger 64, whereas the heated line conveys heated rinse fluid from the heat exchanger 64 to the rinse tank 20. A pump (not shown) may be provided in the fluid circuit to force movement of the rinse fluid.

[0051]In the embodiment illustrated by FIG. 4 the rinse fluid is heated directly by the heat exchange system 62. Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com