Ceramic vape assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

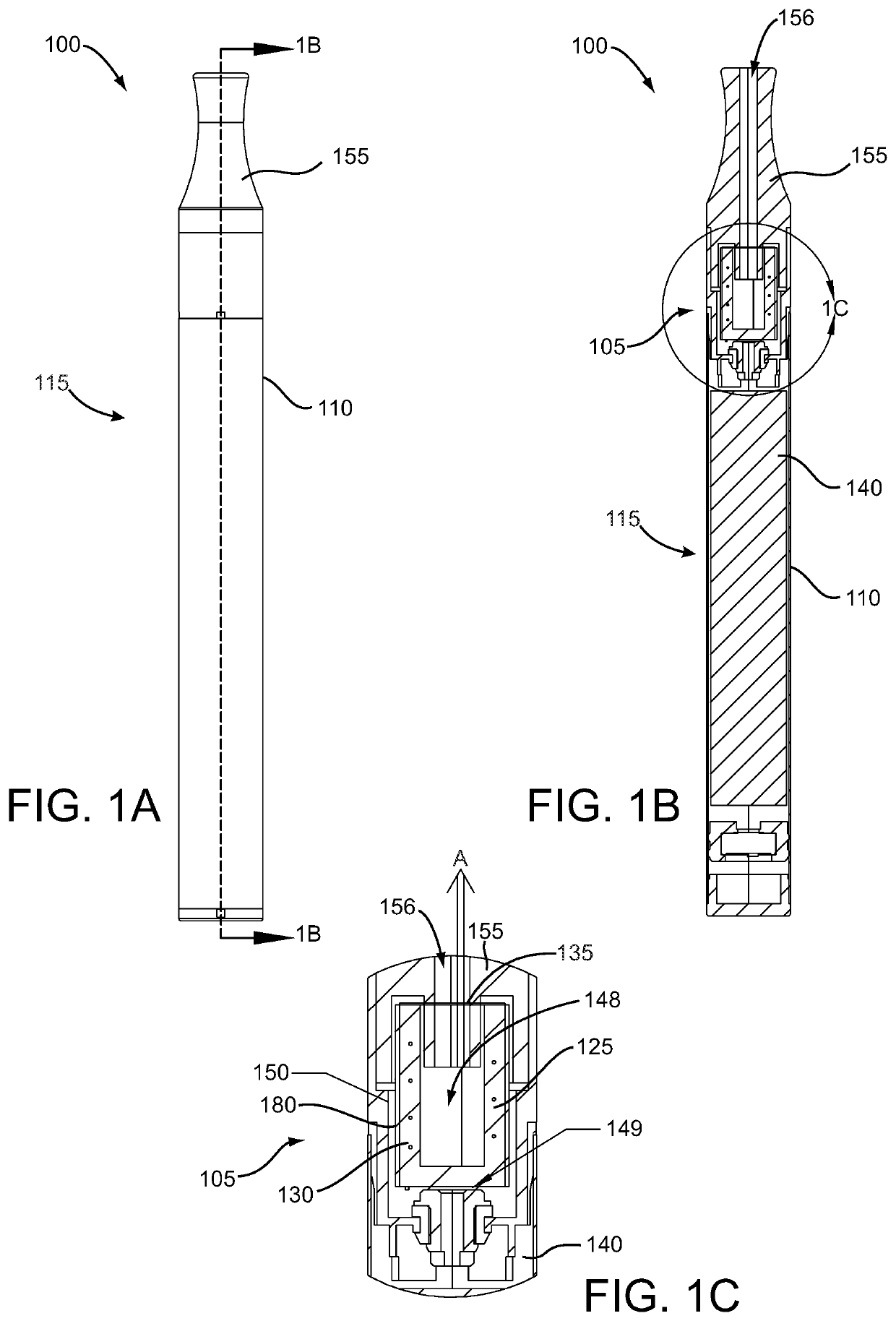

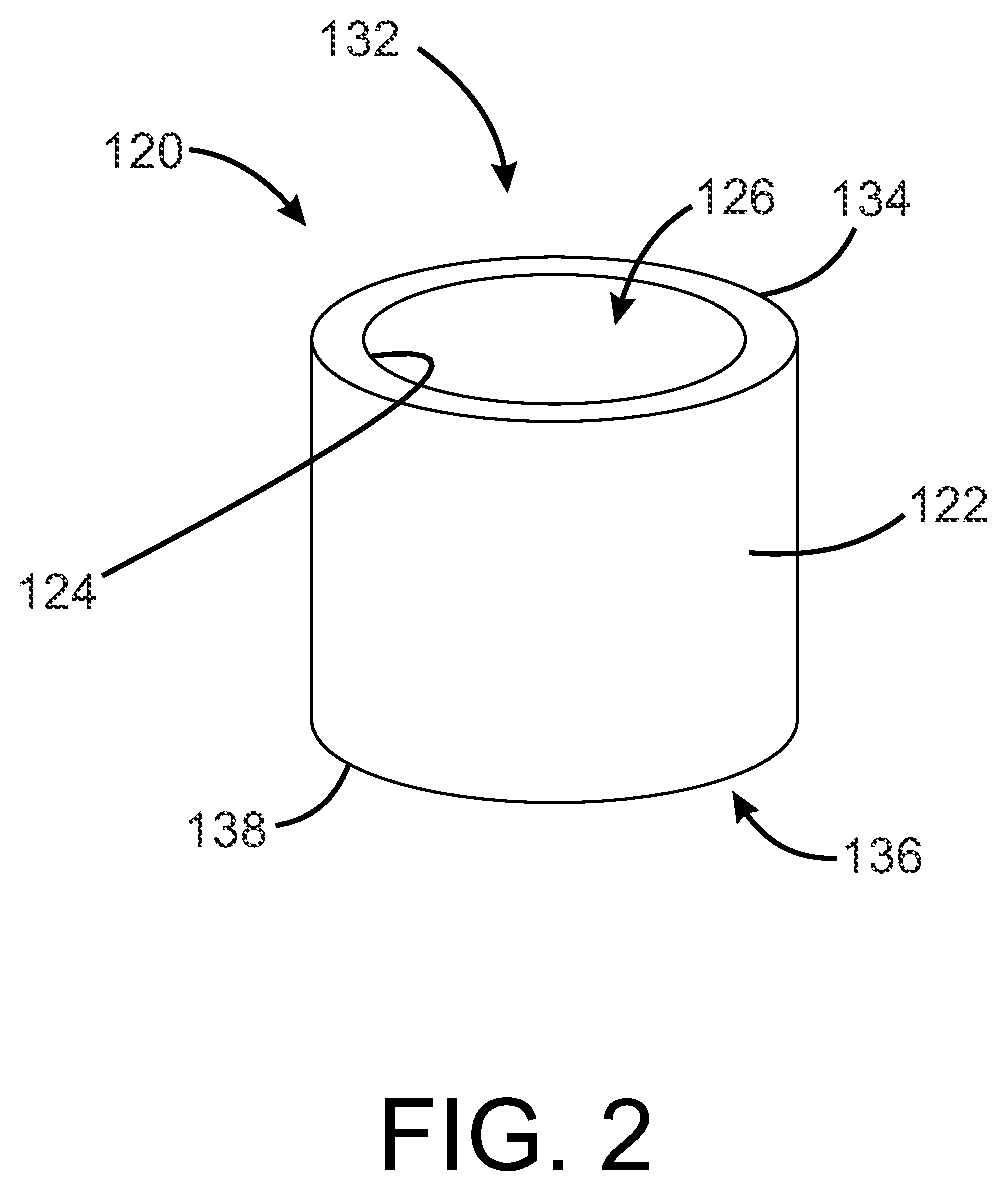

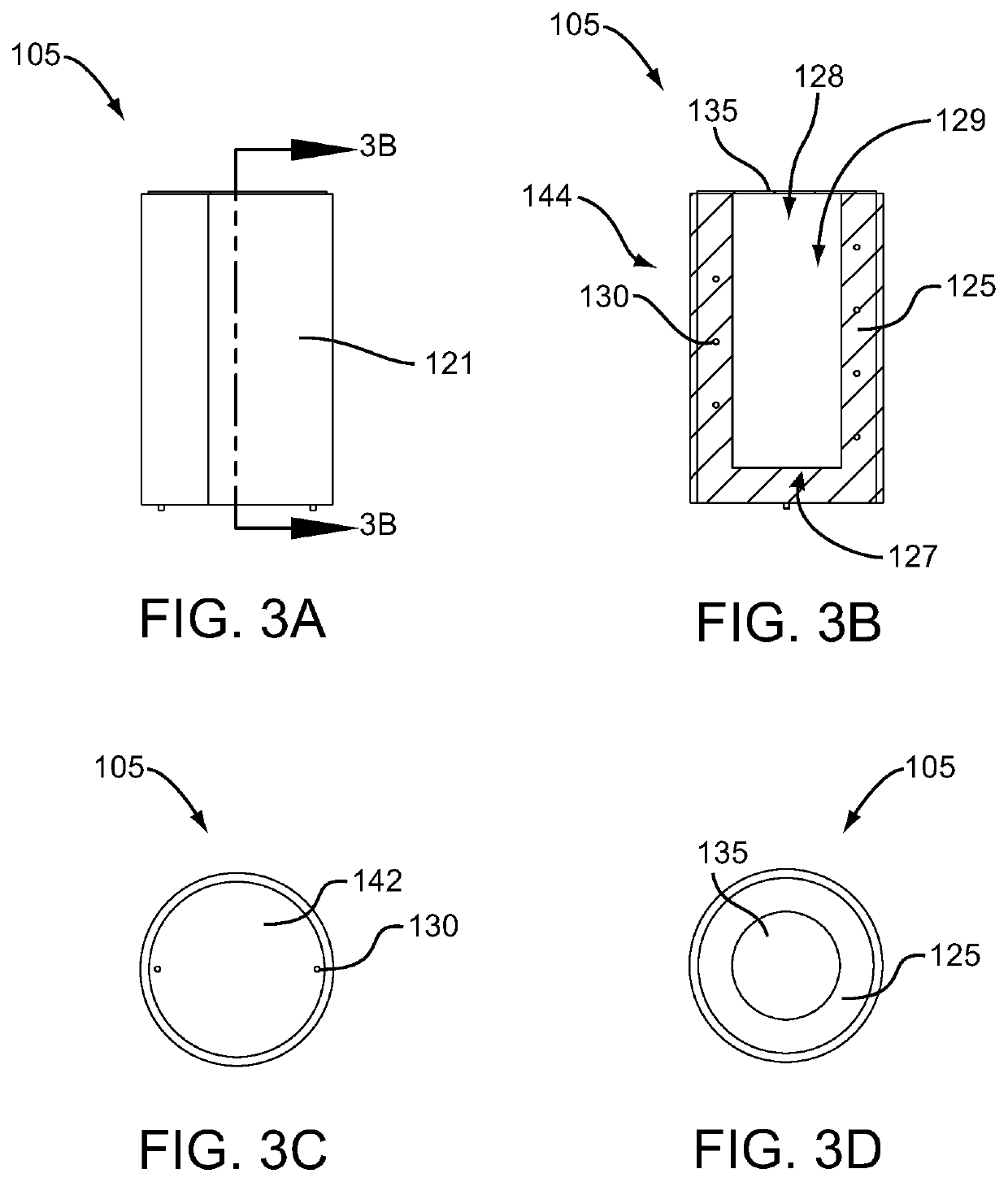

[0029]The present technology may be described in terms of functional block components. Such functional blocks may be realized by any number of components configured to perform the specified functions and achieve the various results. For example, the present technology may employ various atomizers, batteries, airflow channels, circuitry, coils, heating elements, housings, inlets, locking components, positioning elements, mouthpieces, mouthpiece assemblies, outlets, power supplies, plugs, power terminals, seals, tubular bodies, vaporizer devices, wires, and the like, which may carry out a variety of functions. In addition, the present technology may be practiced in conjunction with any one of various vaporizer systems, and the vaporizer assembly described herein is merely one exemplary application for the technology.

[0030]Referring to FIGS. 1-7, in various embodiments, a vaporizer system 100 may comprise a vaporizer assembly 105 adapted to be inserted into a housing 110 of a vaporizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com