Systems and methods for characterization of materials and combinatorial libraries with mechanical oscillators

a technology of combinatorial libraries and mechanical oscillators, which is applied in the field of systems and methods for characterization of materials and combinatorial libraries with mechanical oscillators, can solve the problem that the resonance is designed to ineffectively excite acoustic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

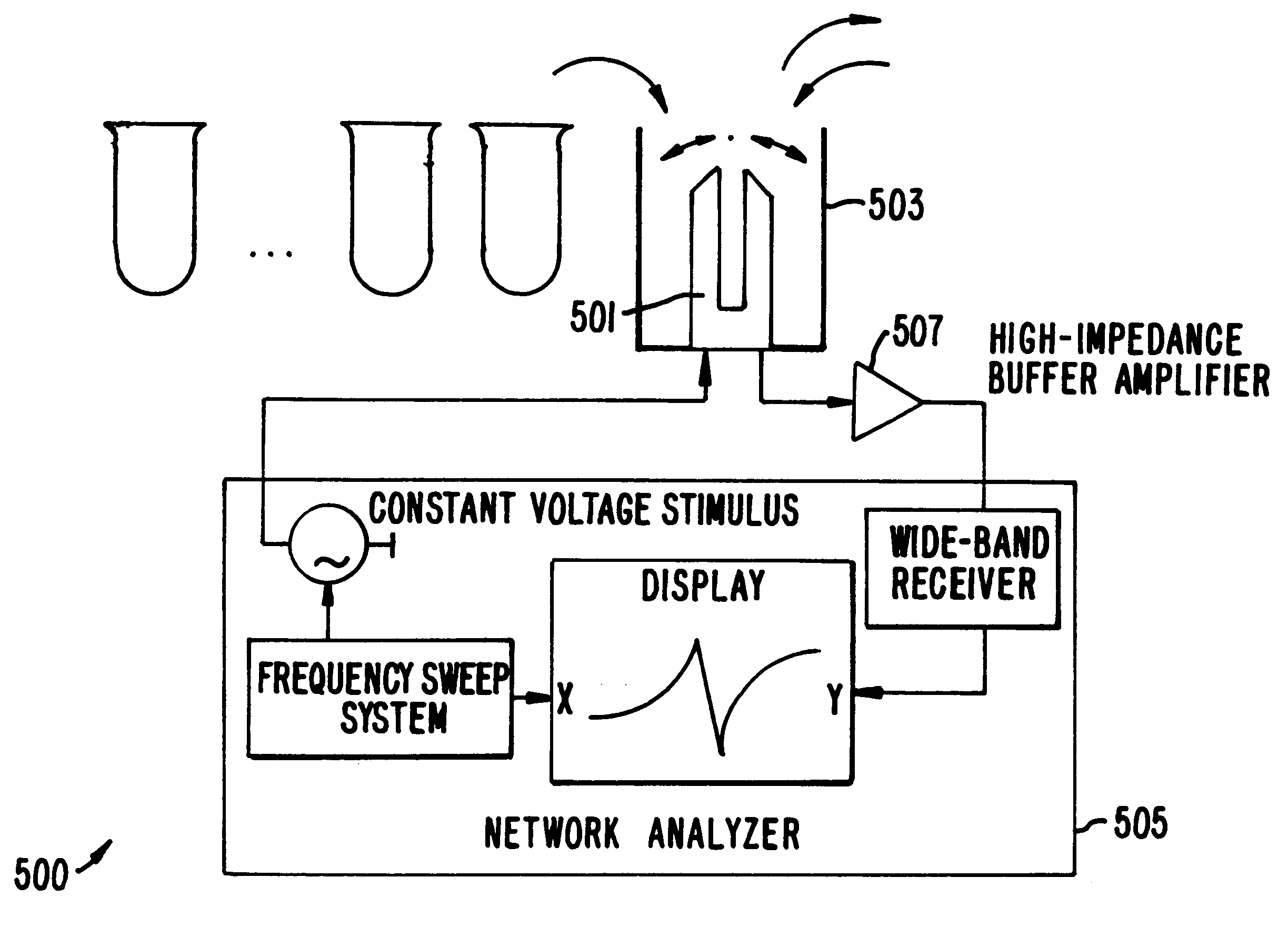

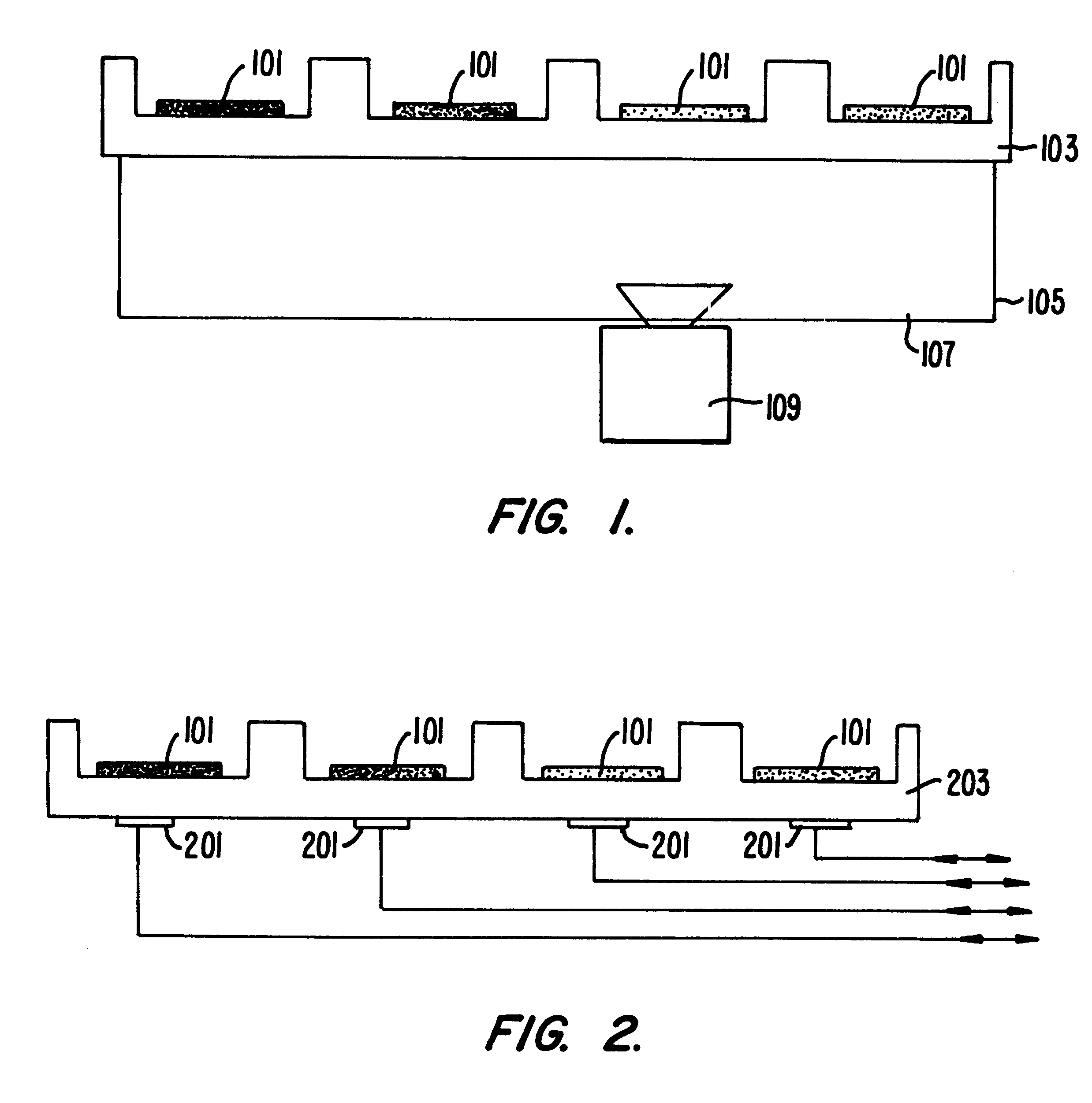

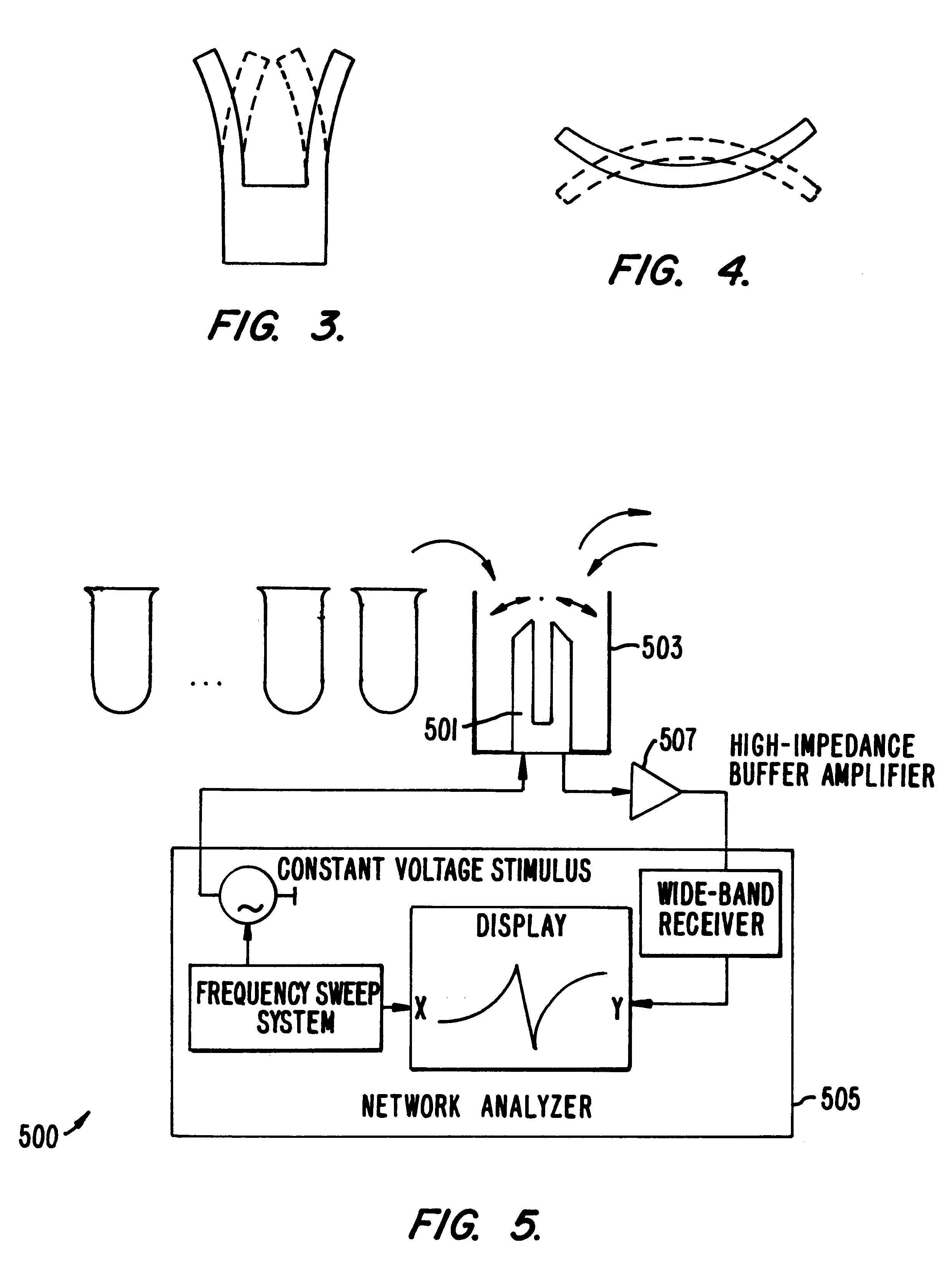

In this aspect of the invention, systems and methods are provided for imaging libraries of materials with ultrasonic imaging techniques. In a first embodiment, an acoustic apparatus and method for imaging of a library of materials is provided. The apparatus includes a device for generating acoustic waves that can propagate into a member or element of interest within a library and a detector for sensing the propagation and reflection of the acoustic waves from the library elements. The source and the detector of acoustic waves may be the same apparatus, typically a piezoelectric crystal. After detecting the acoustic waves propagated from the element, the library and the acoustic wave detector are moved relative to one another, preferably in a raster scanning pattern. The magnitude and phase of the detected acoustic waves and the corresponding scan pattern of the library are recorded so that visual images of the library can be obtained. In addition, by processing the obtained data in ...

second embodiment

In the invention, acoustic waves are generated in a tank filled with a coupling liquid using a conventional multi-element ultrasound imaging head or one of custom design. The library of elements is placed within the tank such that acoustic waves move from the transducer through the fluid, across the substrate, and into the elements of the library. The reflections from each interface and from within the individual library elements are recorded by the ultrasound transducer head. Material properties can be calculated from the recorded temporal pattern. Alternatively, the structure or morphology of the surface of the library elements, or a liquid interface deposited on top of them, may be recorded using a laser probe or other imaging system. Furthermore, since the recorded disturbance is representative of the physical structure of the library, a correspondence between the surface pattern and the geometry and mechanical properties of the library can be constructed. Lastly, the collected ...

third embodiment

In the invention, an acoustic lens excites acoustic waves within elements of the material array. The excited acoustic waves are in a form of short pulses. The magnitude of the echoes produced by the acoustic waves is measured, as is the time delay between the excitation pulses and the echoes from the liquid-material and material-substrate interfaces. The library and the acoustic wave detector are moved relative to one another in a raster scanning pattern and the collected data is recorded. Based upon the collected data an acoustic image of the library can be generated. The time-resolved image can give valuable information about library topography. For example, the first echo provides information related to the impedance mismatching on the element-coupling liquid interface and the second echo provides information about the sound velocity distribution in the element material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface areas | aaaaa | aaaaa |

| surface areas | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com