Digital pulse width modulator for use in electrostatic printing mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

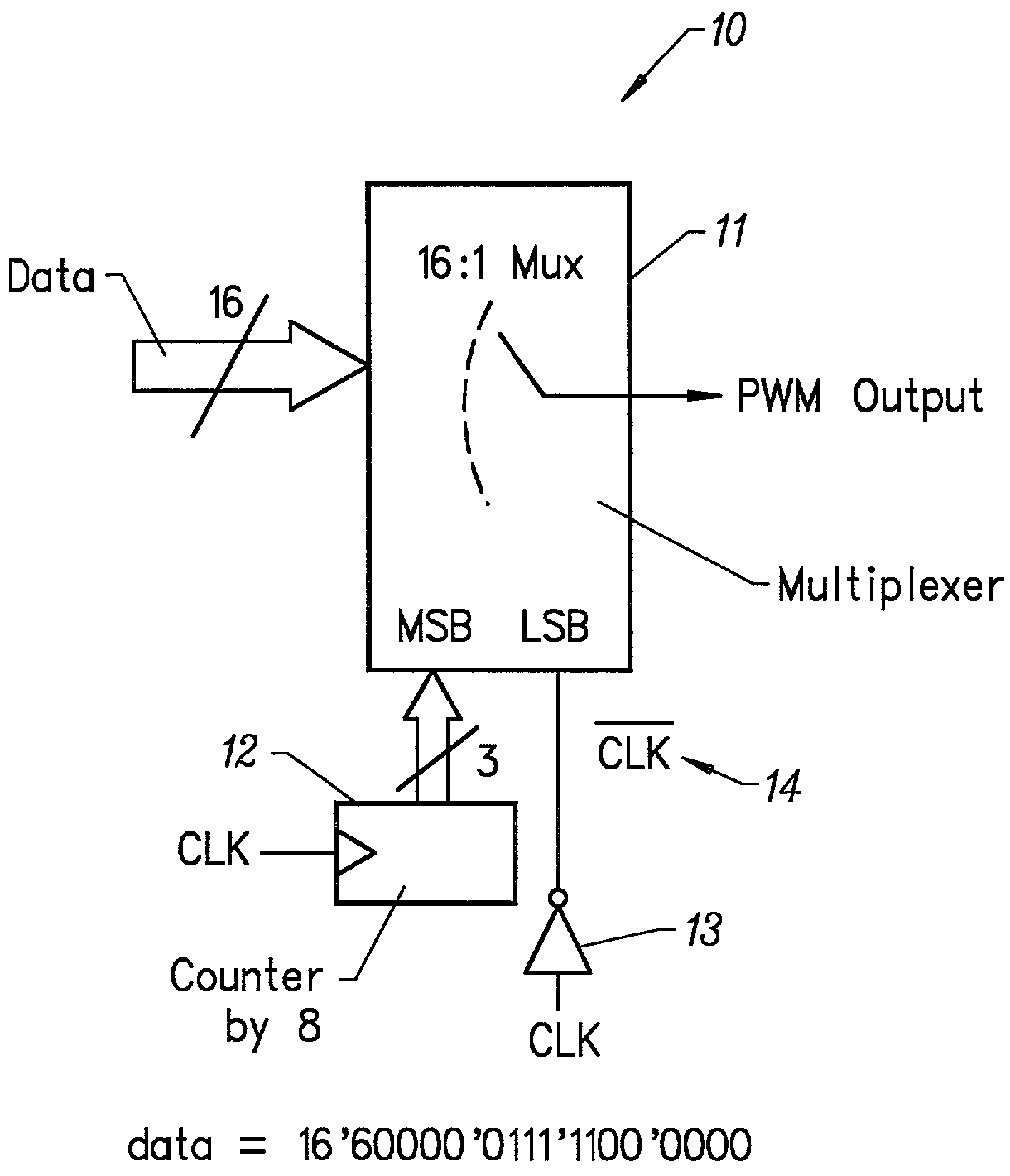

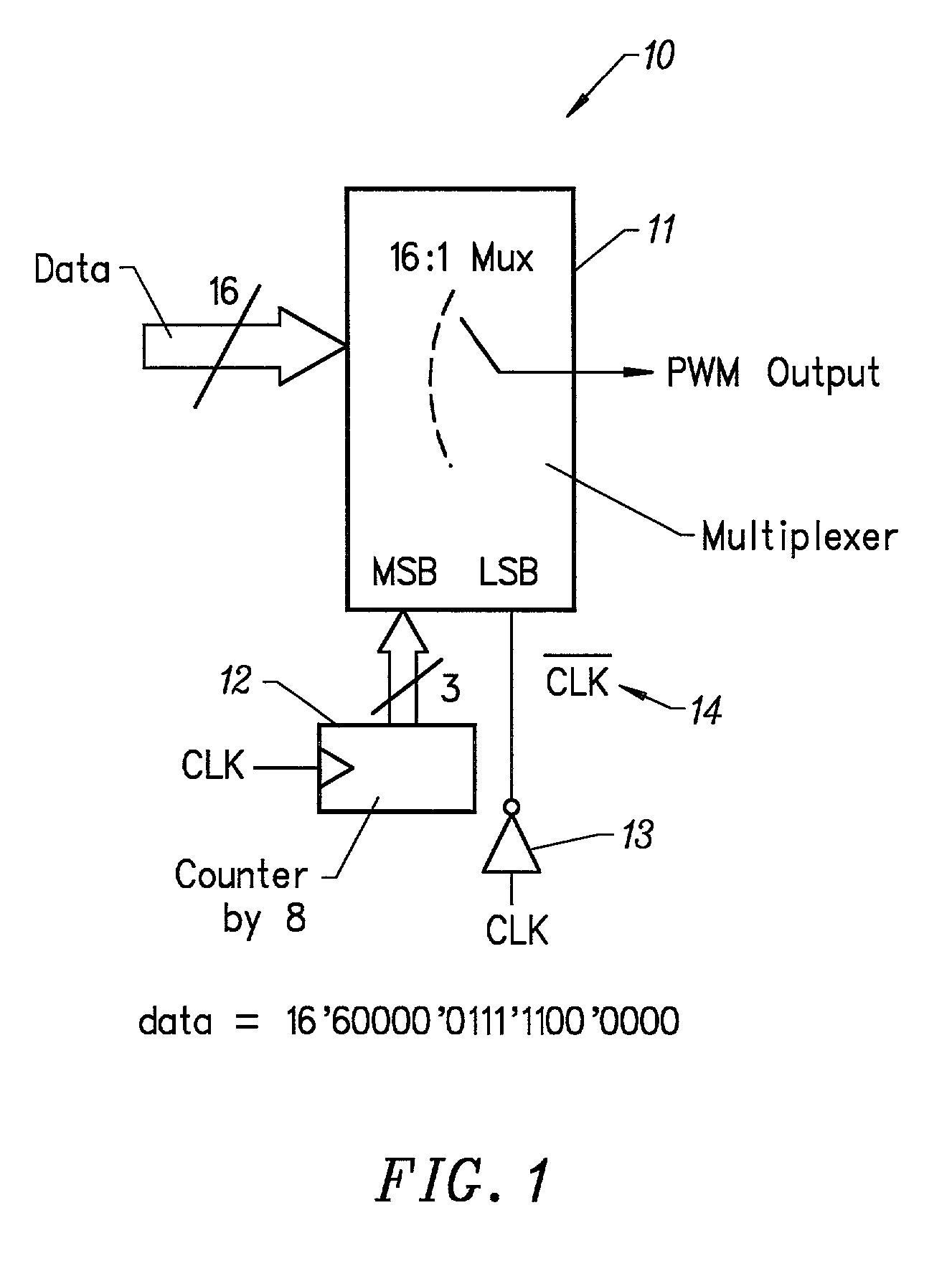

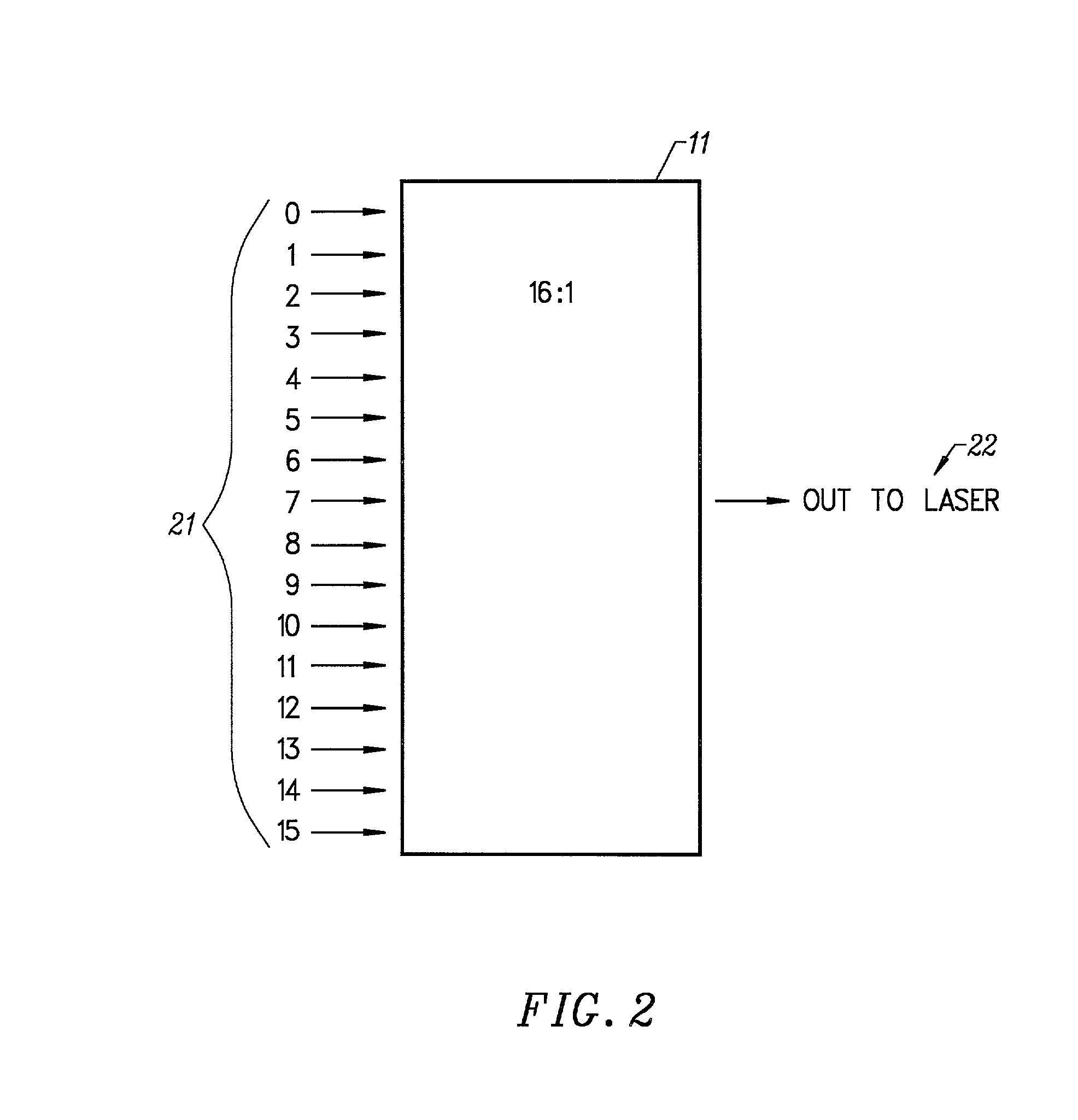

[0012]Turning first to FIG. 1, a system 10 for producing a variable width pulse in an electrostatic printing mechanism is shown. Digital information supplied to an electrostatic printing mechanism of, for example, a laser printer specifies grayscale intensity of pixels to be printed. However, the digital information must be converted to a format appropriate for directly driving the laser, or other light-emitting element. Unlike the digital is pulse width modulators (PWM) conventionally used with electrostatic printing devices, which output one bit on the rising edge of each pulse of a timing device such as a pixel clock, the invention outputs one bit on each of the rising and falling edges of the clock pulse, effectively doubling the throughput of the PWM. Thus, while using the same clock as a conventional PWM, the invention is able to specify each pixel by a 16-bit value, providing much finer resolution, because the 16-bit value can specify more than sixty-five thousand discrete va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com