Traveling hydraulic working machine

a hydraulic working machine and traveling technology, applied in the direction of positive displacement liquid engine, fluid coupling, servomotor, etc., can solve the problems of reducing work efficiency in some type of work, affecting work efficiency, and affecting work efficiency, so as to improve both workability and work efficiency. , the effect of satisfying the combination of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

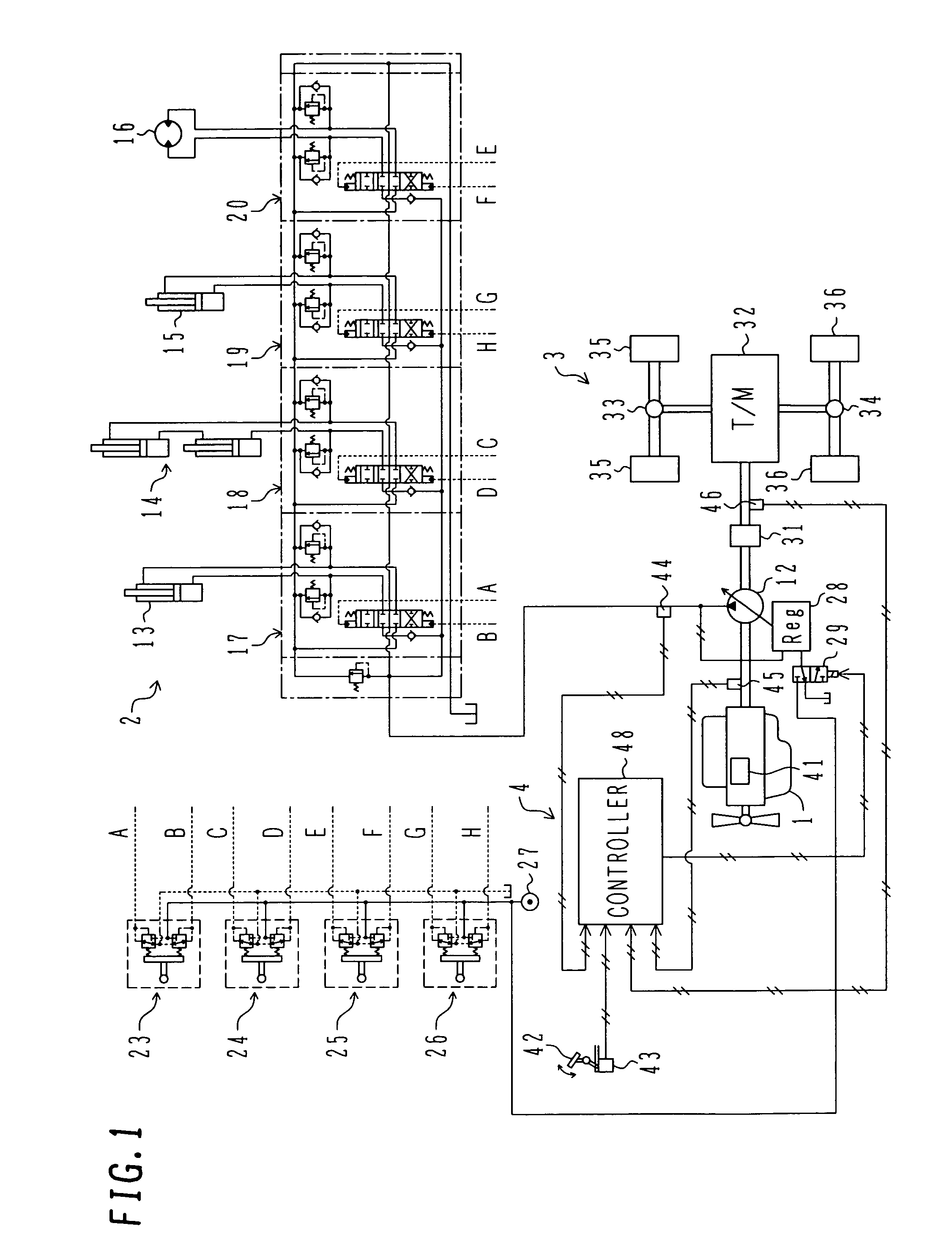

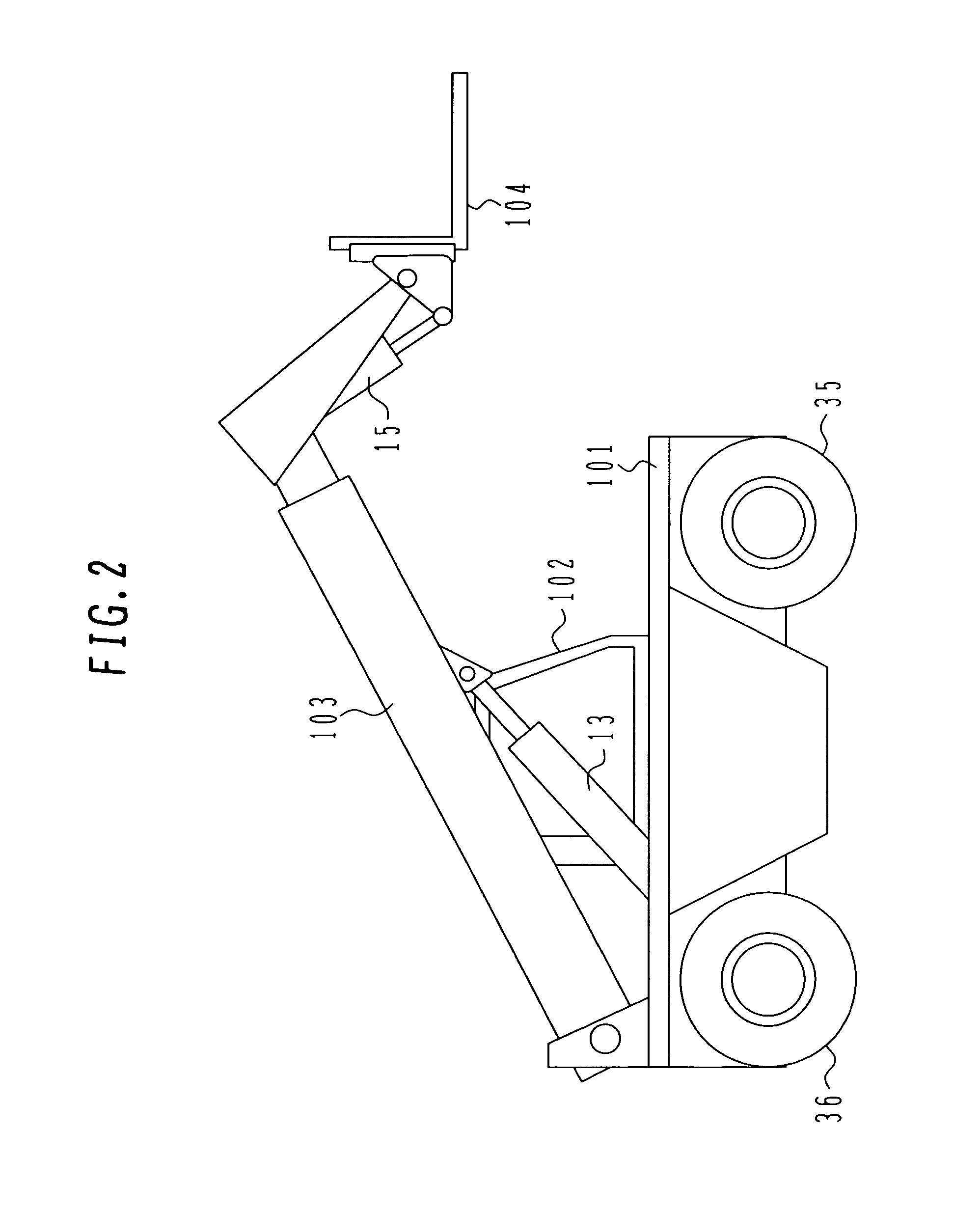

[0083]FIG. 1 is a diagram showing an overall system of a traveling hydraulic working machine according to the present invention.

[0084]In FIG. 1, the traveling hydraulic working machine according to this embodiment comprises a diesel engine (hereinafter referred to simply as an “engine”) 1 serving as a prime mover, a working system 2 and a traveling system 3 both driven by the engine 1, and a control system 4.

[0085]The engine 1 includes an electronic governor 41, and the electronic governor 41 adjusts a fuel injection amount depending on a control input applied from an accelerator pedal 42 (i.e., an accelerator control input), to thereby regulate the revolution speed of the engine 1. In other words, the accelerator pedal 42 serves as a means operated by an operator and commanding an engine revolution speed as a target (hereinafter referred to simply as a “target revolution speed”). The target revolution speed is set depending on the amount by which the accelerator pedal is pressed do...

second embodiment

[0136]the present invention will be described with reference to FIGS. 10 and 11. Note that, in FIGS. 10 and 11, components identical to those in FIGS. 1 and 4 are denoted by the same symbols.

[0137]In FIG. 10, a traveling hydraulic working machine according to this embodiment comprises an engine 1, a working system 2, a traveling system 3, and a control system 4A. The working system 2 and the traveling system 3 have the same constructions as those in the first embodiment shown in FIG. 1.

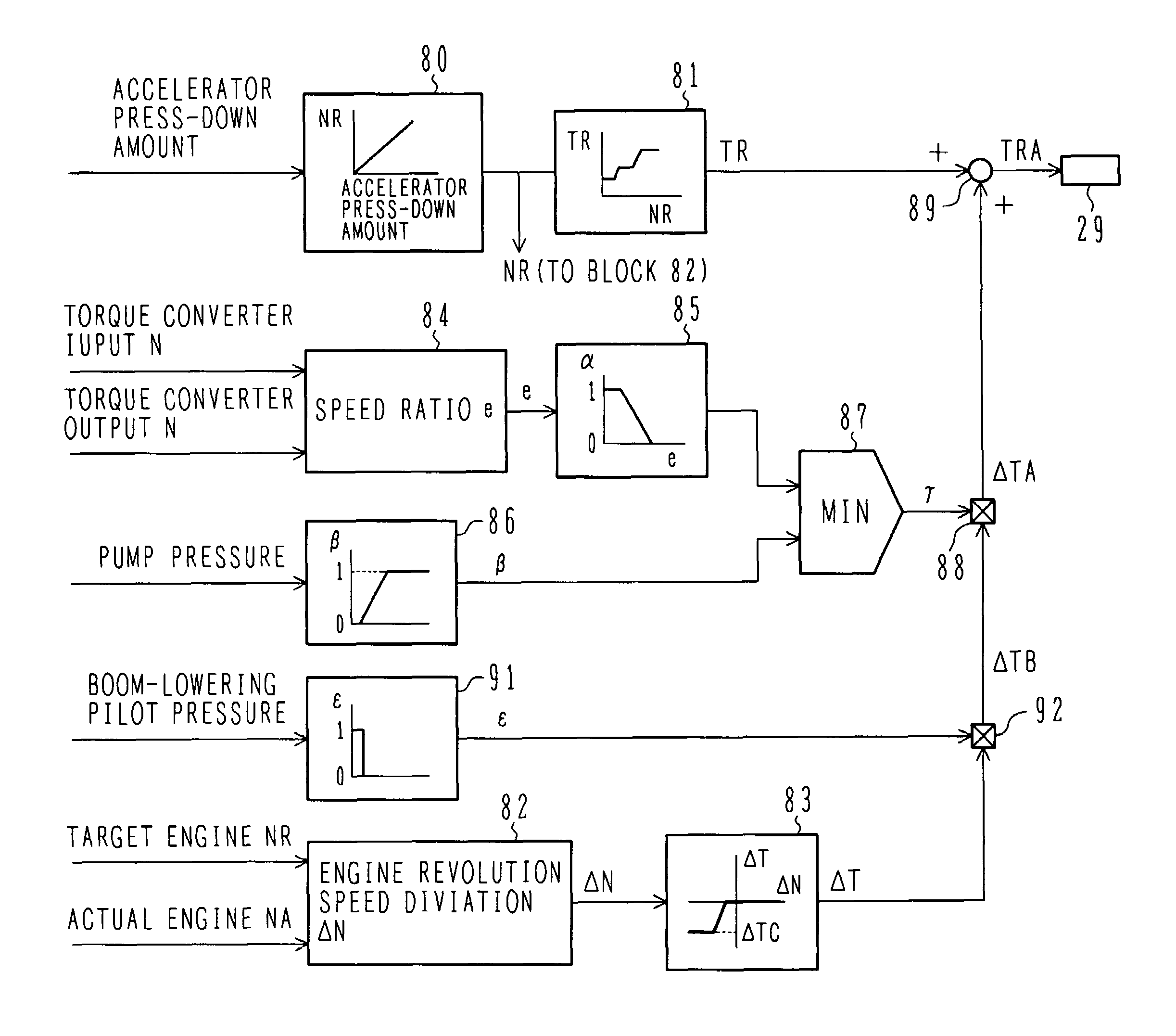

[0138]The control system 4A includes, in addition to the components in the first embodiment shown in FIG. 1, a pressure sensor 61 for detecting, as the operating situation of the working system 2, the pilot pressure in the direction in which the hydraulic actuator 13 is contracted (i.e., the boom-lowering pilot pressure) from among the pilot pressures outputted from the control lever units 23. A controller 48A executes predetermined arithmetic and logical operations based on signals from the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com